@LightBurn i think i fixed it. Fingers crossed

@LightBurn it seems like i did fix that part but the bed still seems off from the laser for framing.

I honestly have no idea what that means - can you elaborate?

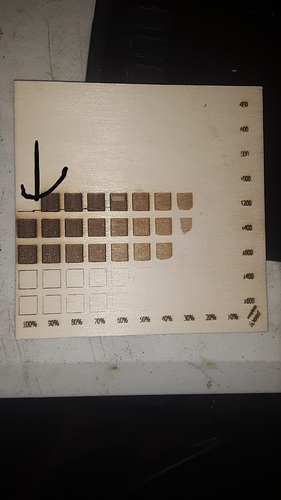

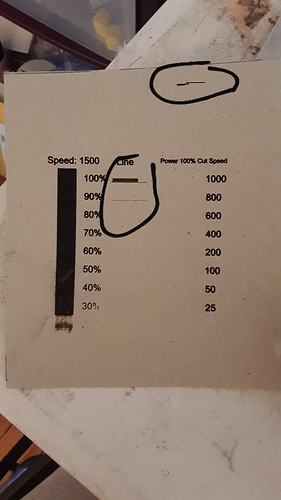

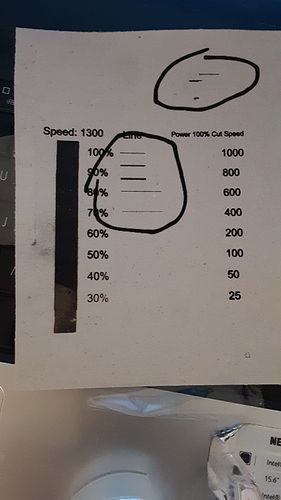

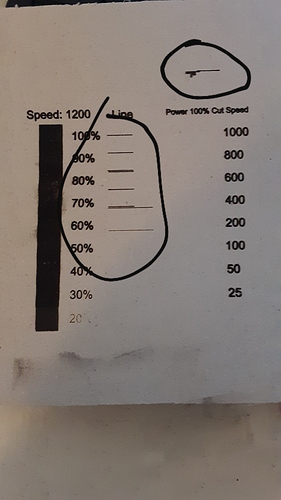

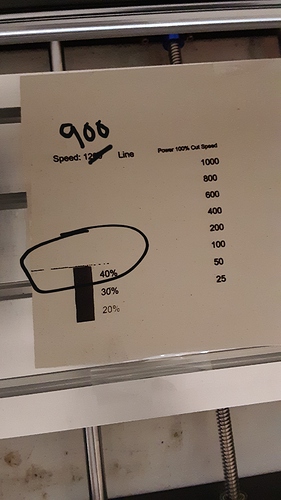

Sorry for my terrible question. I readjusted the bed and it somewhat fixed the issue I was having… But once again had to stop it because it messed up. Can you possibly tell me why this is happening in the picture. The arrow is pointing to a line. As it was working on that last box it made a weird noise I guess jumped over? I’m not sure how to really explain. Maybe the picture will help better

If the steppers ever make a buzzing noise, it’s them losing steps. This can happen for a few different reasons:

- Trying to go to fast

- Trying to accelerate too fast

- Current setting too low

- Sticky rails or bearings

Accelerating too fast and trying to move too fast are the more common ones.

Your acceleration settings are pretty low, but your speed settings might actually be too high for the machine you have. The 3018’s are meant for use as CNC machines, so they use screws instead of belts. To move fast, you have to spin the screws fast, but stepper motors aren’t meant to spin fast - they do best at lower speeds, and lose torque as you go faster, so I’d suggest trying 1500 mm/min as your speed instead of 2200 and see if that helps. (you haven’t said here what speed you’re trying to go)

I don’t have a 3018, so the recommendations given here for them are a bit blind.

@LightBurn thank you for that explanation. When I ran this test I had already changed it to 1600. So would it still be that? I’m going to resend the settings I previously had

If it’s skipping or buzzing when you run jobs, it could still be that. The max speeds set in the firmware are used as the speed for the non-cutting moves between shapes, so you might need to back those off too.

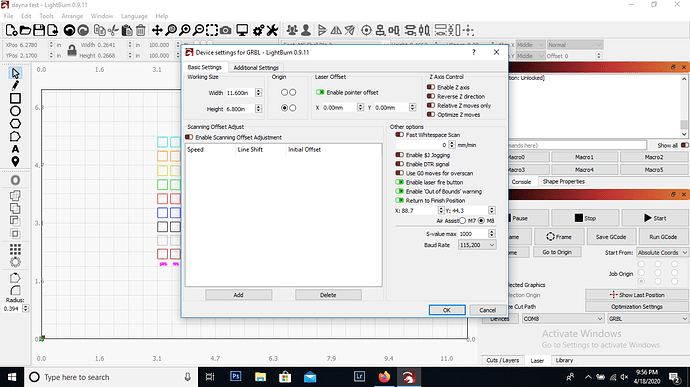

@LightBurn these are what the settings are now. Which $ would I need to change?

$$

$0=10

$1=25

$2=0

$3=2

$4=0

$5=0

$6=0

$10=0

$11=0.010

$12=0.002

$13=0

$20=0

$21=0

$22=0

$23=0

$24=25.000

$25=500.000

$26=250

$27=1.000

$30=8000

$31=0

$32=1

$100=800.000

$101=800.000

$102=800.000

$110=1600.000

$111=1600.000

$112=600.000

$120=30.000

$121=30.000

$122=30.000

$130=200.000

$131=200.000

$132=200.000

ok

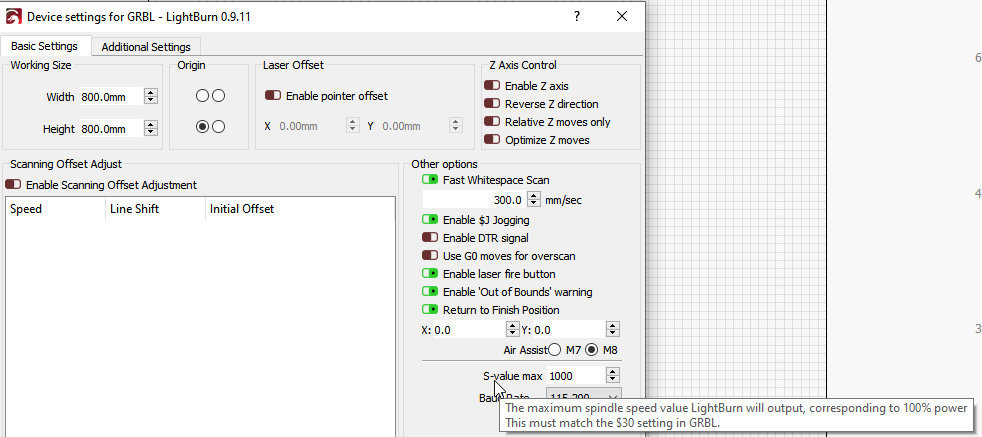

Are you referring to the max spindle speed? $30?

These two are the X & Y maximum speed.

You also have $30 set to 8000 for some reason - that’s going to reduce your power quite a bit unless LightBurn is also set to that number here:

All the $ settings in GRBL are documented and full described here on GRBL’s webpage: Grbl v1.1 Configuration · gnea/grbl Wiki · GitHub

So I should change that 8000 back to 1000?

You can set it to whatever you like, but the two settings have to match - the $30 setting in the controller tells it the largest value it will get from the software is, so it knows what number is 100%. The setting in the software tells LightBurn the highest value to send to the controller, to mean 100%. If they don’t agree, your power settings will be wrong.

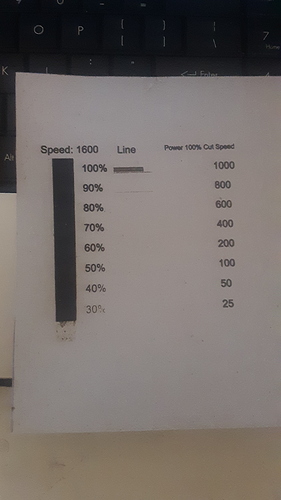

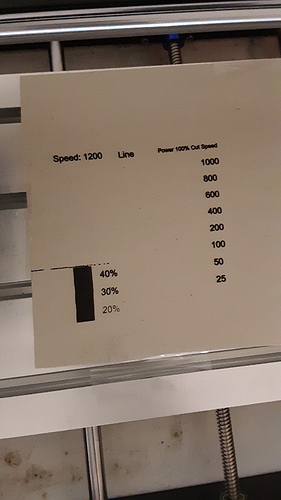

@LightBurn so I’ve been trying to fix. I’m almost there. I finally got it kind of working. But for some reason lines are messing up.

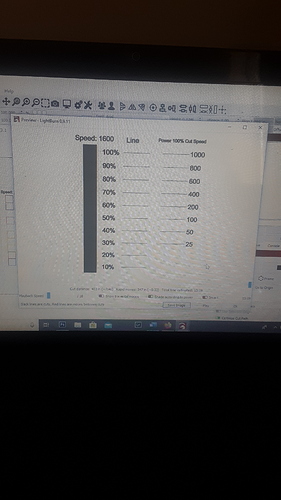

Picture 1. As you see it shows in the preview what I’m trying to do.

Picture 2. This is how it finished. It started doing the lines but then the bed moved idk why because it didnt do it while framing

Picture 3. Shows where it moved to when starting the lines part.

Can you provide any insight please? I appreciate the help.

The bed has to move - that’s the Y axis. From your description, I’m not understanding what went wrong.

I can say that using a diode laser to burn on pure white paper can be pretty hit or miss - white reflects visible light really well, and diode lasers are visible light. You’ll get more consistent results with slightly darker card.

@LightBurn not sure if these pics better explain. It’s not white. It’s just how it may look on camera. The last pic was actually speed 900 and the one that days 1200 but marked out 900 is actually 1200

Ahh - that looks like it’s skipping again. Do you hear the motor buzz when this happens? You might need to reduce that maximum travel speed again. I’m surprised though - so far when others have increased those speeds the machines have held up relatively well. Try setting the $110 and $111 values to 1200 and see if it behaves better.

@LightBurn @Blake

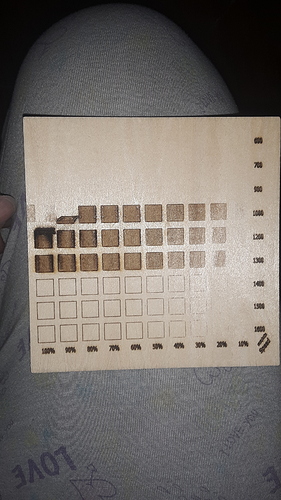

I am not understanding what I am doing wrong. I feel like I am getting closer and closer to getting it but something like this always happens and I don’t understand why. I am posting a picture as well as the $ settings. Please if anyone can give me some pointers on what I may need to change to correct it it would be greatly appreciated. I have also lubricated everything which it moves smoothly without making the loud sounds it was before. The frame is aligned. I am really trying to get the hang of this. HEEELLLP!

$0=10

$1=25

$2=0

$3=2

$4=0

$5=0

$6=0

$10=0

$11=0.010

$12=0.002

$13=0

$20=0

$21=0

$22=0

$23=0

$24=25.000

$25=500.000

$26=250

$27=1.000

$30=1000

$31=0

$32=1

$100=800.000

$101=800.000

$102=800.000

$110=1600.000

$111=1600.000

$112=1600.000

$120=60.000

$121=60.000

$122=60.000

$130=200.000

$131=200.000

$132=200.000

ok

Make sure that the machine doesn’t have any dirt obstructions on the rails or threaded rods that move the machine around - it looks like it was fine except in that one spot, but it was moving slower there than before. It’s not likely that you’re doing something wrong, and more likely there was something physical that happened - stiff spot on the rails, maybe slightly out of square… Hard to say.

I don’t see anything wrong with them, no.