Rather than being the stubborn old guy I am and not asking for opinions…I am going to ask for some help.

I have been doing the White tile method on my 50 watt CO2 laser with good success but it will not do some images as well as a diode laser can doing the white tile.

I have people always asking me to make them so time to buy one or two diode lasers.

All I will use them for is white tile. So what has been the best machine overall for this. There are so many to choose from I realize best to ask those who know.

So I appreciate exact recommendations and input. I would not know which power to get…going with the more is better may or may not be it so…opinions are welcome.

I realize this is GRBL so I will have to get used to that as well.

add one to your 50W?

Buying a separate stand alone diode laser like an ortur etc. not adding a diode module to the CO2. A stand alone setup like many have was looking at the Ortur master 2 15watt…but that’s just a guess for me. Maybe an Eleksmaker…again…?

Well I agree with you while the k40 or k50s are good they dont have the quality IMHO of a very good diode.

Myself and a friend are admins on the Endurance laser forum and we both use our own purchased Endurance lasers, these are 10 watt and are excellent but a little pricey, there is also a good version from Matteo Borri who makes the L cheapo range of Lasers in the US, I have one and again this is an excellent diode, both offer full lifetime guarantees which you wont get from any chinese laser, both will cut 3mm wood on the 10 watts in one pass with the right lens and air assist working but its takes time to learn that to get it right.

The l cheapo is a lot cheaper on the mark 7 but its very good. the other things with these 2 makers is the duty cycle is very long unlike chinese lasers.

We are in the process of rebuilding our K40’s to make very much larger beds, bigger than ever before by welding in a complete new section into the existing cabinets. this will give us a bed of around 650 by 750.

we are also hoping with a bit of jiggery pokery that we can in fact be able to use the same gantry to run the c02 laser and the diode but obviously not the same time. there is a bit of work to do this but the new beds are based upon the eleksmaker design so should be fine to do it, might just have to manually switch over some wires.

I still think we are not yet ready to dump the diodes , they still have a place and I personally like the style of engraving they do over the K40 or c02 laser. Long may they do as well. also try OPT lasers I think from Poland which are good but no lifetime guarantee. Have fun…

Hi there. Did you ever buy a diode laser for doing tiles? Thinking along the same lines.

from what I’ve read, it has always been said that the best laser diode for engraving on tiles is 2500mW (2.5W) due to the thin and rounded shape of the diode and consequently its focus, used in the Norton method (by Norton himself). Now, new collimating lenses have also been used that better concentrate the focus.

A 2500mW laser diode is quite cheap compared to higher power ones.

I have an Eleksmaker A3…not impressed on tile…but just after I bought it there was a Yora 5.5 watt for sale cheap so I got that…like it better…better diode laser module I think and I can run it at half power to engrave.

However that said I still default to my 50 watt CO2. It’s faster and I get just as good results with an 1.5” lens. Now granted I am not pushing Uber resolution like some are….I don’t have a need to see just how small of a pixel I can get down to.

For me swapping to bullseye 1 2 3 spray paint was way better for the higher power of the CO2. If I use the yora I like the standard white paint used. The bullseye seems…mmm…thicker …maybe a higher percent of titanium dioxide…leaves a thicker fused black coat….which is good for a CO2 imho

I, too, have a little Eleksmaker A3 machine with 2.3W laser module and I have been very happy with it when doing NWT ceramic tiles…

Not yet Nicky Norton quality… but passable IMO and fun to do. Haven’t been able to do nearly as well with any of my other lasers, diode or CO2.

Also, just discovered this today in another LB thread… same machine and laser module.

Having fun again rediscovering what that little laser can do…

– David

Thanks. Will look for the paint!

Nice. How long does it take to do a tile? Might be fun to explore as I can’t seem to get good results on my CO2 laser.

About an hour and a half… 1:30 to 1:45, typically. That also depends on the DPI (interval) you set in as well… more lines, more time.

Thanks for the info!

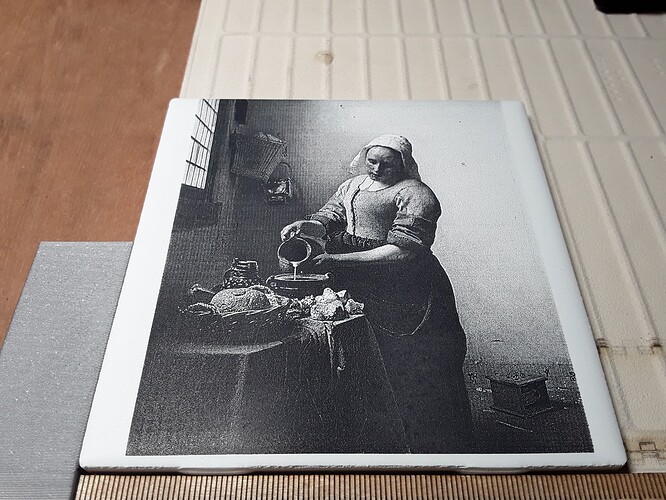

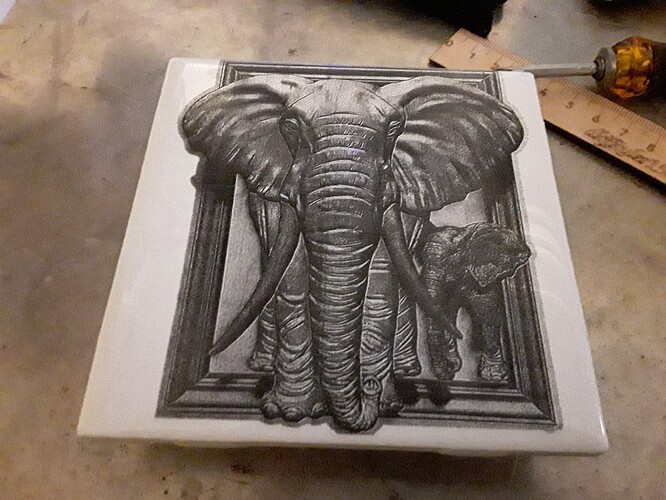

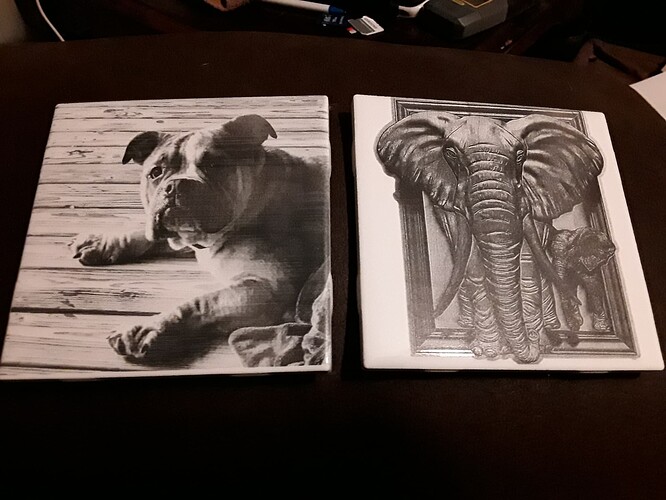

After an abortive attempt last evening, finally got a decent burn on flat-white painted ceramic tile…

Cleaned the lens, slowed down to 1000 mm/min, 100% power, 339 DPI… and a little less than 2 hours. Cleaned off paint with acetone and steel wool.

– David

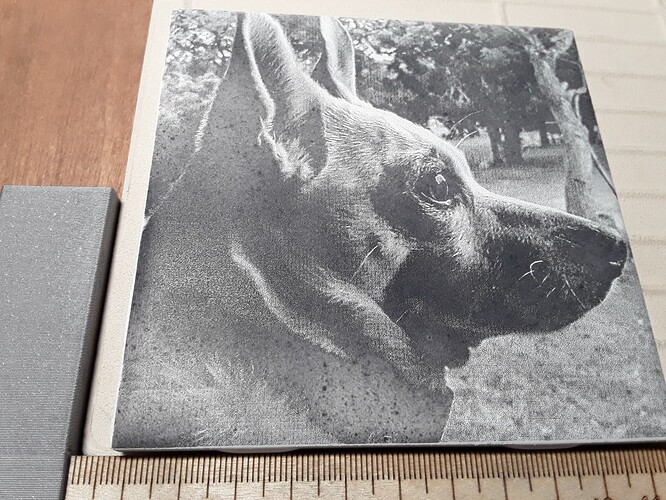

Kids got the new dog, so it seems expected that I do something about it…

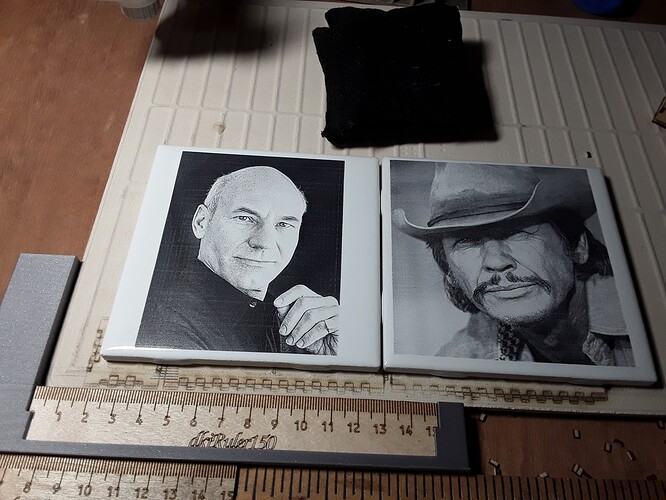

Mentioned cleaning the lens last post and I think it really had a positive effect. I was able to up the speed and power back up to previous levels (1200 mm/min and 85%) and started getting far better results…

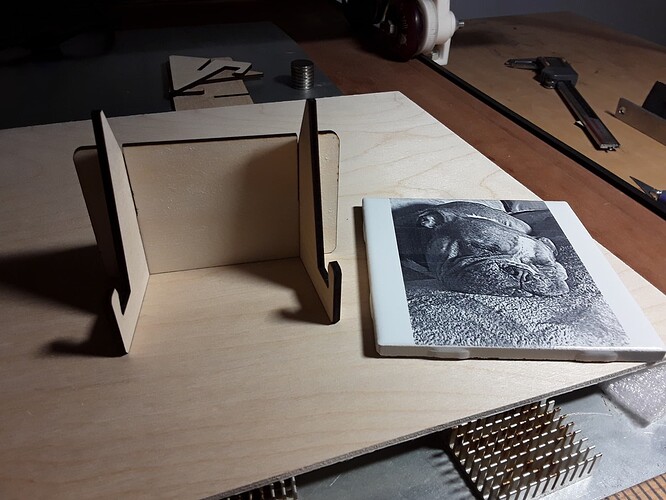

Daughter and I decided we need a small photo/tile stand… so cut one from 3mm plywood with the Neje A40640 laser module. And, of course, had to laser another photo of dog…

Finally, after a tough day (and following the dog’s example)… I took a nap.

– David

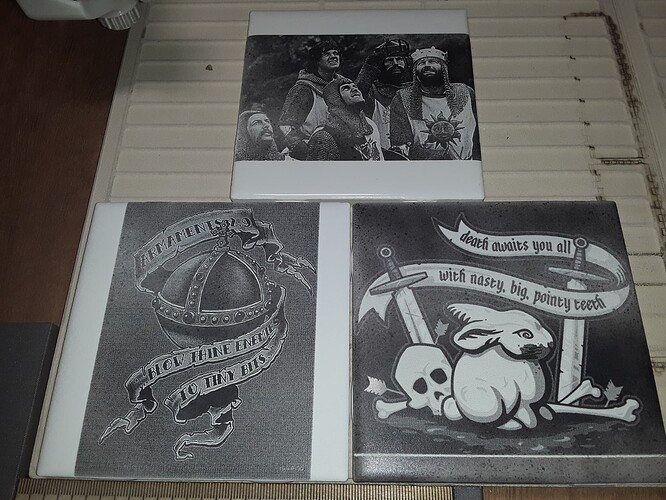

Wow those really came out nice…I’d be happy with that all day long. Yah one thing with nwt method is it is very sensitive to nailing the exact power density levels to get it to look great.

And I like the Baltic birch stand…I make similar pop together stands for air plants👍

@dkj4linux you use grayscale or dithering?

Not grayscale. I’m using LB Jarvis or Stucki dithering for these photos, 254 to 339 DPI, 1200 mm/min and 85% power with a Banggood 2.3W laser.

Merry Christmas! – David

Thanks for infos… Merry Christmas and Happy new Year to you and family

I bought an American Photonics 1.5" for my K40 and I also love the detail. It’s only 40w. However having said that, I don’t like the cut with 1.5". If I’m not going for super detail, I use a 2" meniscus lens. Gives adequate detail and cuts well. Been doing some hybrid projects of fine detail with my D1 diode then dropping it in the K40 and aligning using lightburn camera then cutting. Works out well on items where you have a detailed cut but also want fine engraving.