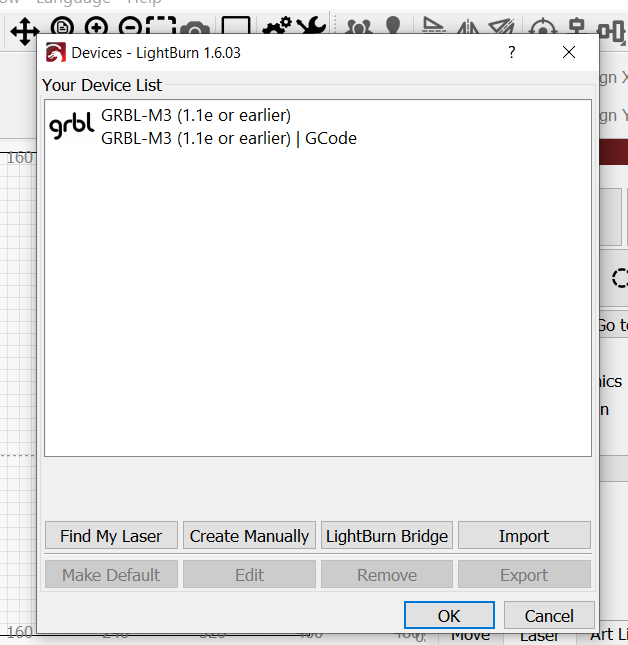

the grbl-m3 is the only option availible to this machine i guess, should I uodate drivers?

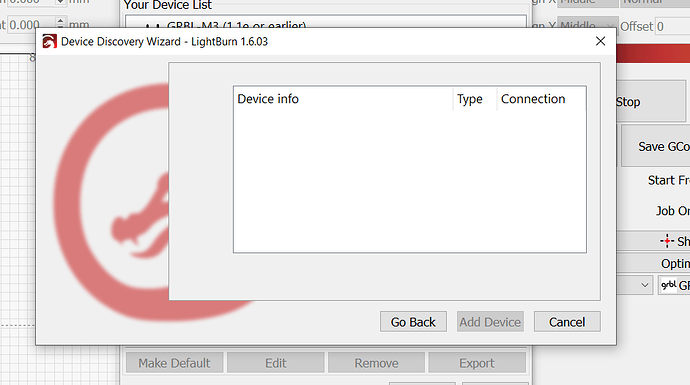

What do you mean by this? Are you saying no other device profile options show for you when you attempt to edit the device profile? If so, can you take a screenshot of what you’re seeing?

No. This is unrelated to the driver that is used to communicate to the controller. The configuration I’m referring to is on the LightBurn side and determines the device type associated with your laser.

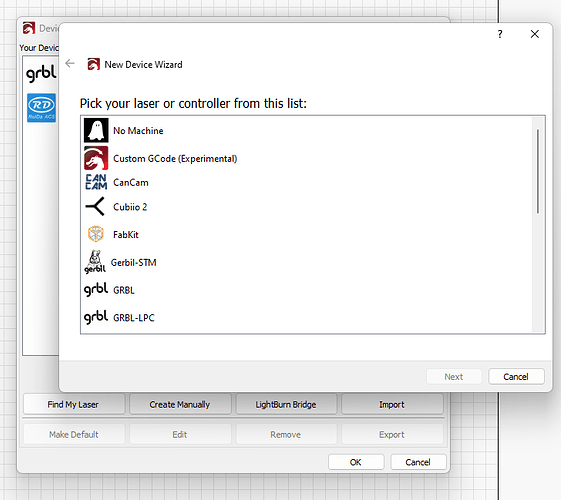

Fox alien is not in there, should I just choose gble?

Please follow my instructions from my earlier post. Select your device named "GRBL-M3 (1.1e or earlier), then click Edit. Then change the device type used to GRBL.

what is this going to do for my system? should I run the tests again in the morning to see if anything changes?

The primary benefit is that you will get variable dynamic power. This allows the controller to dynamically adjust power to accommodate acceleration/deceleration of the laser module due to changes in direction. The result is more even burning across motion.

This makes no difference from a mechanical perspective so won’t affect anything done earlier to resolve the axes calibration.

Perhaps try rerunning the GrundTest. You should get more consistent burn levels even at the corners of design elements.

I truly appreciate all your time the past few days, you have been a huge help. I will attempt a new box tomorrow and let you know how it goes.

Sorry about the confusion, I’ve had to expand my deadine for this project, I hate having to do that. But Id rather get it done right, and be late than loose a commission. Thanks again

I know you’re probably overwhelmed by these attempts to help your situation. But, if I may suggest (I didn’t read all the comments to see if anyone’s suggested it) checking the alignment of your machine’s frame to the bed?

I had a similar issue with boxes where the they would line up correctly but gradually become misaligned the further the cut went. Like you I was looking at belts, timing issues, axis calibrations, etc. with no joy. Turns out my frame was tilted compared to the bed so as the laser went across the X axis its relation to the material was changing, getting further away and changing angles which cause the fingers to be off.

Thanks for the input, I recently added Z brakets that I made in CNC mode, during assembly I made extra sure that everything was plum and square. I will double check after a few more tests just to make sure. Because I was so careful, I didn’t think of that, but I did have to move it to it’s home.

I will look into that if my proto type doesn’t work out.

thanks

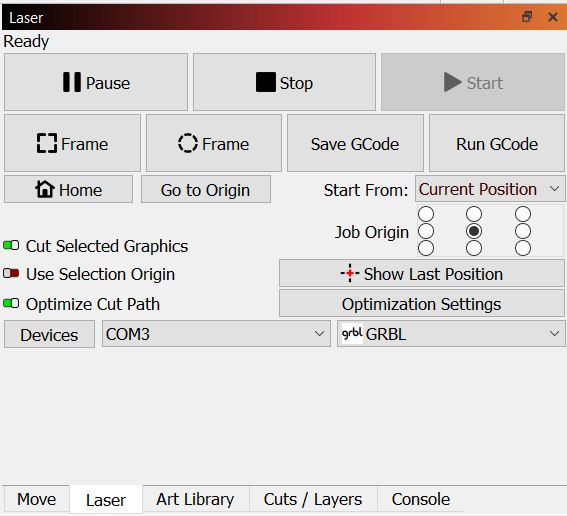

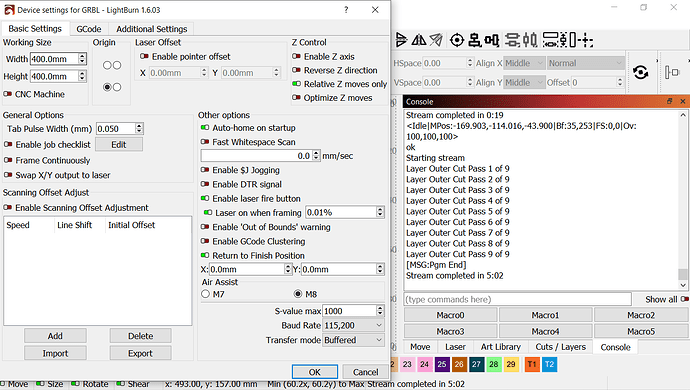

Tried multiple test this morning, After updating the GRBL my Macros are gone, and my laser is not cutting. any idea what the baud rate is for a 20W laser?

Changing the device type should not have changed anything with the device itself. Did you create a new device or modify the one in place?

Baud rate is not related to the laser module. It’s a function of how the computer and controller communicate. If you are able to communicate with the device the baud rate is fine.

When you say not cutting, are you saying the laser is not firing at all? Or it’s not cutting all the way through when it used to?

I suspect the root cause is due to this value in your GRBL configuration:

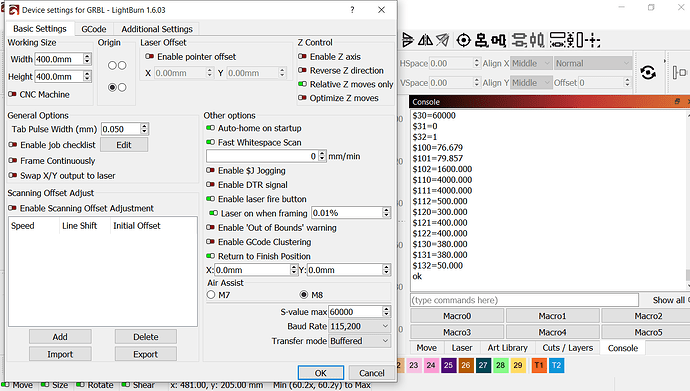

This is a highly unusual value. Do you use your machine also for CNC function? In any case you have two ways to resolve this:

- Change the

S Value Maxsetting from 1000 to 60000 in Edit->Device Settings - Change the value of $30 to 1000 to match

S Value Max.

If the 60000 value is deliberate then I’d suggest following the first method. If not deliberate then I’d suggest changing $30 to 1000 as that’s a very typical value and will be more inline with others.

If you want to do the latter then enter in Console:

$30=1000

These are the current settings, Laser is Firing,

The first attempt, didn’t even mark the 4.75 foam material.

I changed the S val/$30 to 60000 and no smoke. You would think that going through a lighter material would take less time and power before moving to plywood.

Was the laser light more intense than prior to the change? What are your cut settings?

What is happening instead?

I went back to the GBRL 3M and now I’m getting some cutting action. Changed $30 to 90000 and matched S value.

[4.75 box proto.lbrn2|attachment]

(upload://iWNk4IroMgXh1euTNp3OMs4IqiP.lbrn2) (195.5 KB)

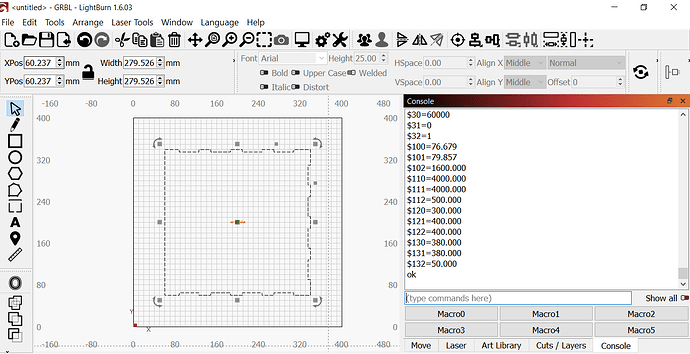

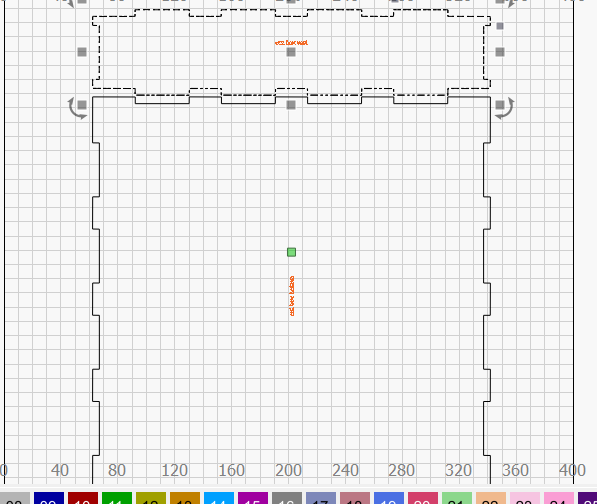

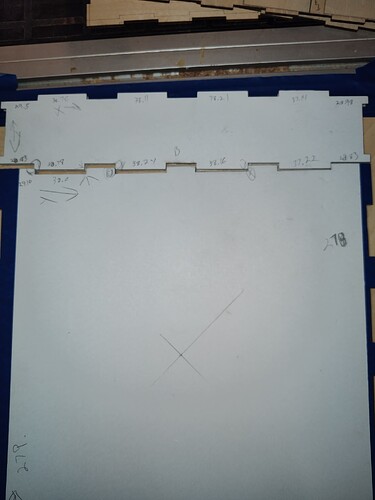

SO there is some good news, The machine is not cutting over @12mm. However, The file and the results are still not lining up properly.

There are no divided segments, and all looks to line up and fit on the screen.

What are you trying to address with this change? Unclear to me.

It looks like you may have been trying to upload a file here but has not gone through. You may have replied before the upload was complete.

I’m looking at an older version of the file and can see where portions don’t align. I assumed this was to address kerf issues but I’m now questioning that.

How did you determine the 0.063 kerf value that you used when generating the design?