Hi all

Im brand new here and just as new to laser engraving

I wanted to keep costs to minimum and was looking to purchase the monport 40w or omtech k40 C02

I am getting confused because I am getting conflicting information now on what laser I need to engrave stone/pebbles

Do I need a C02 or a fiber laser?

Here below are a couple of vid’s showing what I would like to achieve

https://www.youtube.com/watch?v=z61sxkEFdT0 https://www.youtube.com/watch?v=cQZDu20CFrw

Any advice very much welcome

Thanks

legepe

Both of those videos show fiber lasers, so that’s likely what you need.

AFAICT, a CO₂ laser heats the rock, rather than ablating the material, and will just mark the surface.

Looking at posts on “slate engraving” and “stone engraving” may give you some idea about what’s involved.

Thanks for reply… looks like I need a fiber laser then. Does anyone have any recommendations on what wattage and/or what brand is up to this type of deep engraving on pebbles?

Ive looked on aliexpress to try and keep costs down, but does anyone have any experience with these chinese type brands? any recommendations are very much welcome

The higher the wattage the quicker it will engrave… there is always a point where this doesn’t apply anymore, such as when too much heat is put into something and it physically shatters…

The second link you provided states it’s a jpt 50W machine in the video.

How the laser will effect the rock, depends on the rock. Most of the time it shatters from heat stress, lava rock melts and some sedimentary rocks engrave like the ones in your video going back to sand from the applied heat.

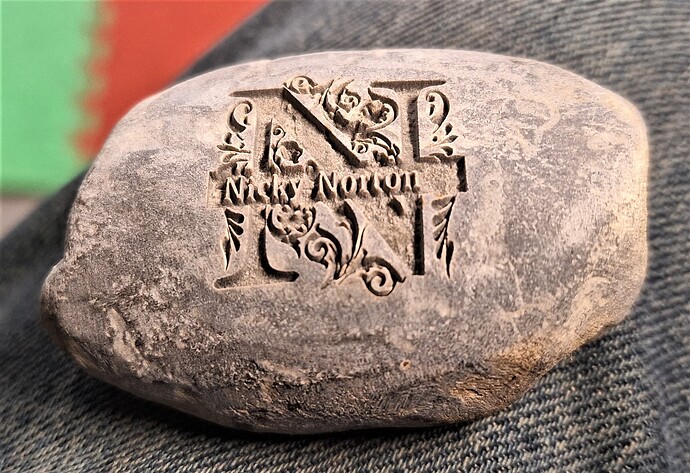

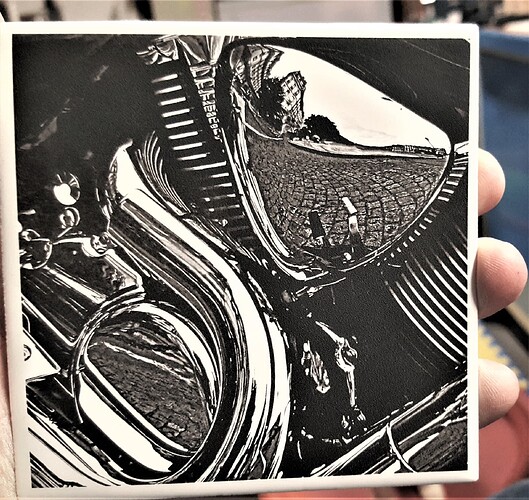

This is a piece from my back yard… doing the materials test… notice it doesn’t really chip at these settings, it heats up enough to turn to glass.

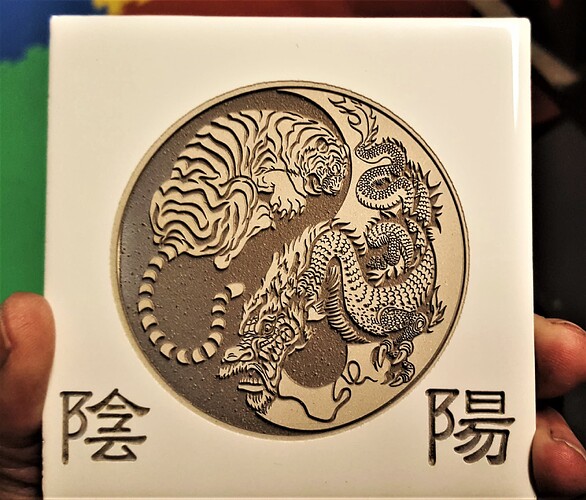

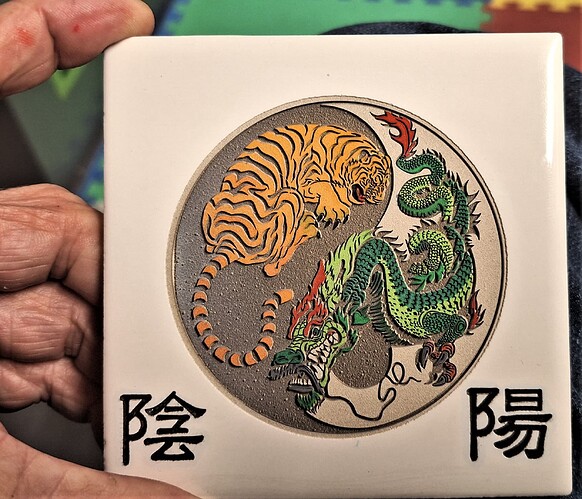

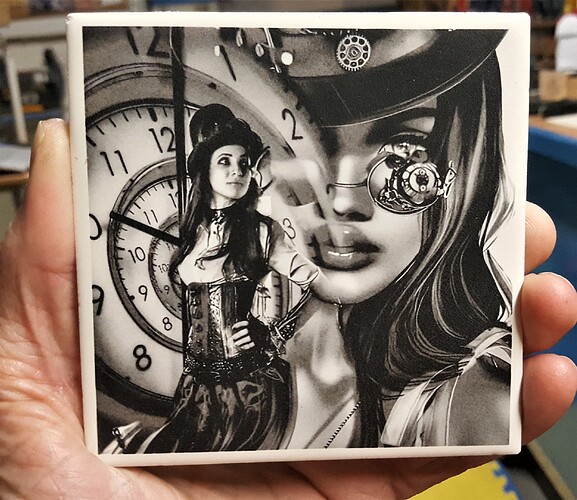

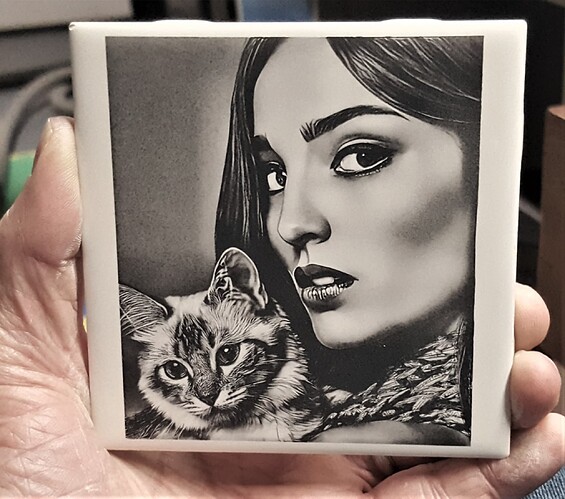

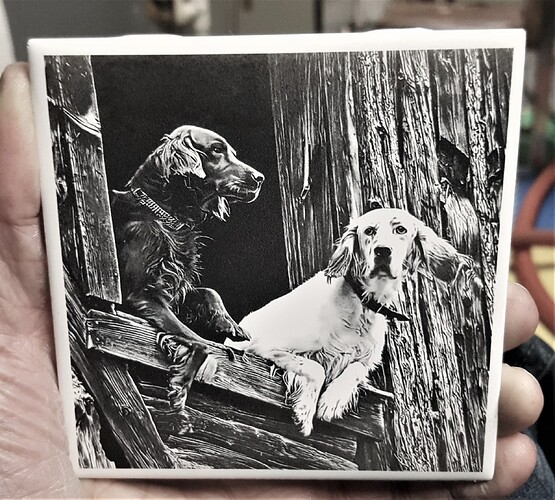

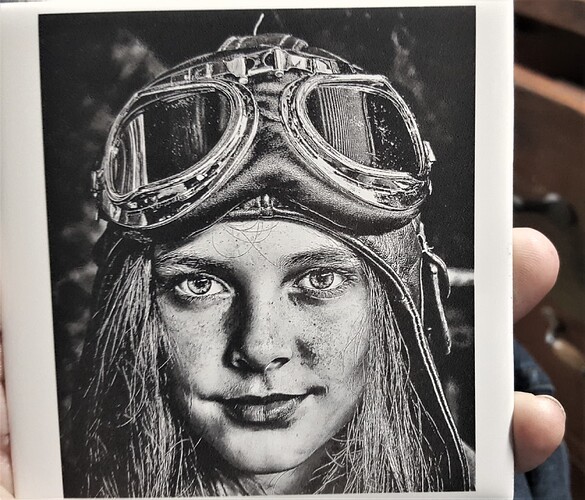

You can do things with porcelain tiles…

I’d suggest you stay under 100W… as soon as you get to 100W, the lenses < 100W go from about $60, when you get to >=100W they now cost about $480… the type of glass must be different to handle the additional power. I got my fiber from CloudRay, my Co2 from OMTech.

I’ve heard good things about Haotion Lasers and a salesman named Pascal, I believe.

I like having a tall column, so I got one with an F425mm lens that covers about 300x300mm area.

The column is about 800mm. The rotary is a couple hundred mm to it’s center line, so it has to have enough clearance to allow a rotary with a long lens.

The source is very important… they have Q-switched and Master Oscillator Power Amplifier (MOPA) types are the most common. A MOPA allows more adjustments and control over the output pulse. I’d suggest a lower power MOPA rather than a higher power Q switched machine.

I’d highly suggest you email them all and ask for quotes when you figure out what you want or can’t decide. A lot of times they make you a deal knocking off hundreds…

Don’t know everything, but ask and we’ll try to help you out.

![]()

Thanks everyone for your advice with this!

I will contact various companies including JPT and i will mention you Ricky in the processes

Can anyone tell me what are the advantages of a fiber over a C02 for engraving stone/pebbles/tiles etc…?

Also, I know Ive said that I need a machine for pebbles but are you not more restricted with size of object to be engraved with a fiber vs a C02?

Excuse my ignorance here, I am a complete newbie!

The machines operate completely different as far as the beam/material application of power.

A co2 is an analog device that uses a CW mode when operating… A 50W co2 is producing it’s power continuously.

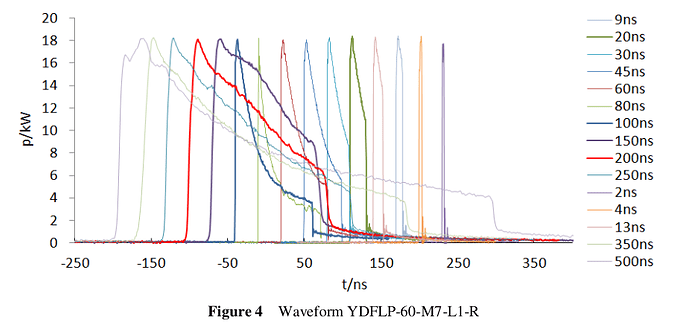

The fiber is a pulse laser… my 60W fiber produces 18kW pulses… this is much more destructive to a lot of material.

I have a few diode lasers, along with a China Blue co2 and a JPT M7 MOPA.

IMHO, for doing rock, you need a fiber… A co2 can mark stone, like slate, but it’s poor at applying any kind of depth.

![]()

Thats great… thanks very much for this information Jack!

Would this machine in the 60W be ideal then?

I totals £2423.74 including the shipping. is that a good price?

My other question, as i am a complete newbie. are you restricted on the size of material/object with a fiber laser?

Most of the machine specification I can tell about are ok.

The only problem with this machine is that I doubt this machine will work with Lightburn.

It has a Z axes stepper motor. That usually indicates EZCad3, which isn’t supported by the current software.

It needs to run EZCad2 to be Lightburn compatible. Of course, the add says EZCad, no specifications if it’s 2 or three…

I don’t buy stuff from Alibaba… I’ve been shafted too many times over low cost items. Many people had fine results… but I repeatably get taken, well twice, so I avoid them.

It’s your money – so it’s your choice. Use a credit card.

![]()

Hi I checked this machine with the seller and they say it is lightburn compatible, it also states on their website that it is EZCad2

Ive also, found this machine by the same company - rayfinetech, that looks like it may be able to do stones/pebbles, but I’m yet to receive a price

Would you say this machine is ok for what I need?

MOPA 100W 60W 50W Fiber Laser Marking 3D Dynamic Focusing Fiber Laser Engraving Machine for Mold Coins Deep Relief Engraving from China manufacturer - Ray Fine Tech

OR

Is this one ok? priced at $3500

https://www.speedy-laser.com/240416155700.html

The “Ray Fine” has a “Feeltek” motorized head:

Thanks for this information ednisley… I am obviously out of my comfort zone here with the different lasers, but want to learn more. My initial budget started around £500 to £600 pounds, but it was with a degree of ignorance towards what I want to achieve with a laser, and what is required!

I was thinking initially to just dip my foot in the water so to speak, however, if I am going to spend several thousand pounds on an idea of something I know very little about, it has made me think, possibly i need to somehow recoup some of the costs of the machine, and set out to learn everything I can with it and maybe turn it into a small business (even if its just a sideline) Maybe I am just thinking crazy as I am very rural where I live, so I would think that this is not advantageous either. but my budget just seems to be increasing and increasing on what i may be prepared to spend. I would now consider buying a machine that provides the latest features and technology, but do not want to find Ive made some sort of mistake. If you, or anyone else here has recommendations as to what I should do, or buy, it would be very much considered and appreciated

The machine with the 3d laser head came in at $5400, and as you have pointed out it cannot be used with Lightburn… I am confused with all these options!

Either type of laser will work for you. However, if you’re lucky enough to be able to afford a CO2 laser from the start you would be ahead of the game. The biggest difference between the two lasers is that the CO 2 will do the job (any job) quicker and much less power. Additionally, the real difference between the CO 2 and the fiber is whether you want to go professionally or not. A CO2 will allow engraving faster with less power, while a fiber laser could require double the power or more to engrave. What it really comes down to is if your looking foe speed to get the project done. Many people will tell you that you cut a 6mm board just as fast as a CO2 laser, by increasing the power and lowering the speed. The results will not exactly be the same, cause by increasing power, you can and most likely will have burn marks around your cut. By the way I have both and run testing all the time cause things like the strength of the laser change, I am sorry but I can’t give any exact settings. - Good Luck and if you can afford it, I’d buy a 40 Watt fiber and a 150 watt CO2 laser and you’ll see what I mean. This what I have my 40W is for small slow jobs and my 150W is for bigger commercial jobs. Again, Good Luck & keep in touch, I’d love to see what your decision was and perhaps we can trade stories…

It’s a large boat, hop in and join us ![]()

![]()

Thanks guys for your advice and comments, much appreciated

I think ill end up purchasing a fiber mopa lasa to begin with and learn what I can with that, then contemplate the C02

So far, I am getting quotes from two different companies in China - Speedy-laser, and Rayfinetech, anyone any experience with them?

Can anyone recommend courses that I could go on to learn more about Lightburn and the use of these types of machines?

This guy knows everything lightburn

Click me here

Hi again… Would you say this is a good approach for getting started within the world of laser engraving, or should I look to get something different?

“I think ill end up purchasing a fiber mopa lasa to begin with and learn what I can with that, then contemplate the C02”

Ive been in touch with a couple of machine suppliers for prices and advice, and theyre telling me a fiber laser is not what I need… and it is the C02 for deep engraving stone

In the process Ive also spotted a used HPC Laserscript 6090 60 Watt - 2.5 years old, for £2750

Im very confused as to which type of machine would be best for me to get into this? And any further advice from any of you guys would be very much appreciated!