I have a diode laser ortur master 2 15w. I installed a camera dead all the steps successfully all the images taken were under 0.09 except for a couple that were 0.12. when I jog the laser to the 4 targets they go right in the center but when I put an object in the middle and select the top corner it jogs about an inch away from it. What can I do to fix this

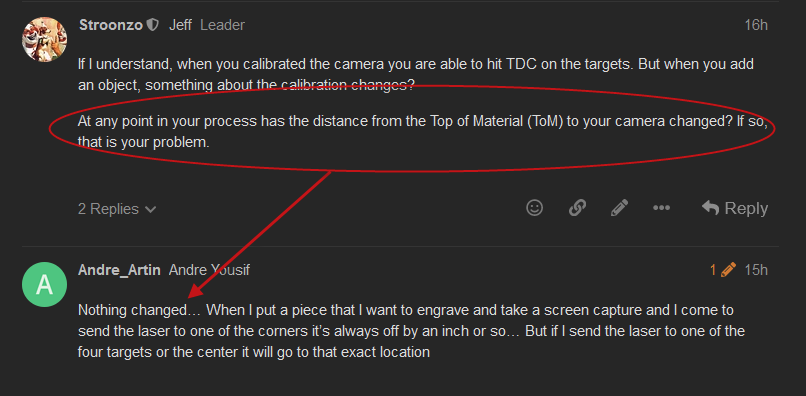

If I understand, when you calibrated the camera you are able to hit TDC on the targets. But when you add an object, something about the calibration changes?

At any point in your process has the distance from the Top of Material (ToM) to your camera changed? If so, that is your problem.

Nothing changed… When I put a piece that I want to engrave and take a screen capture and I come to send the laser to one of the corners it’s always off by an inch or so… But if I send the laser to one of the four targets or the center it will go to that exact location

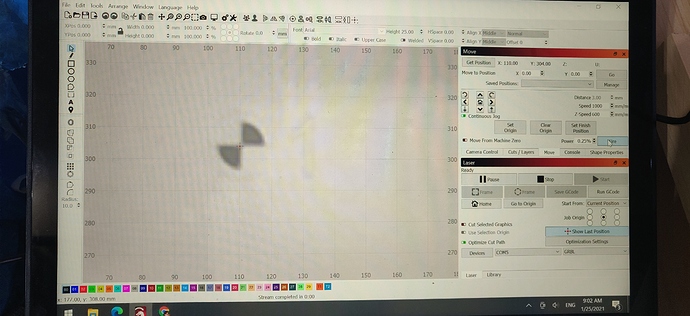

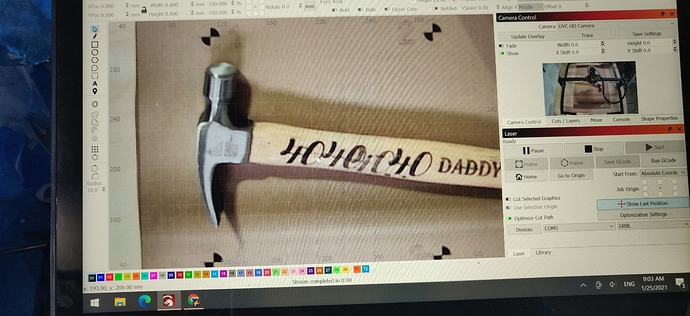

For this example:

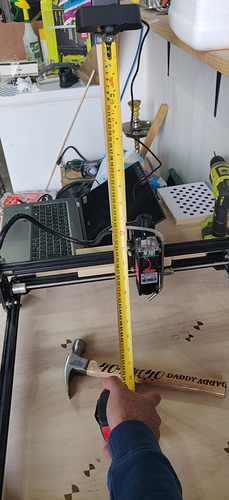

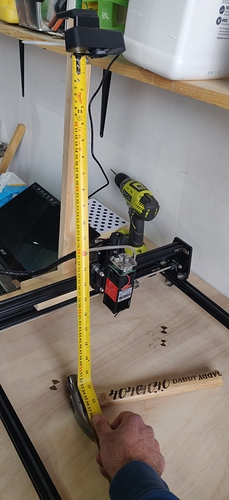

Please measure and share with me the distance between the LightBurn camera and surface of the material with the filled targets.

For this example:

Please measure and share with me the distance between the LightBurn camera and the top surface of the hammer’s handle.

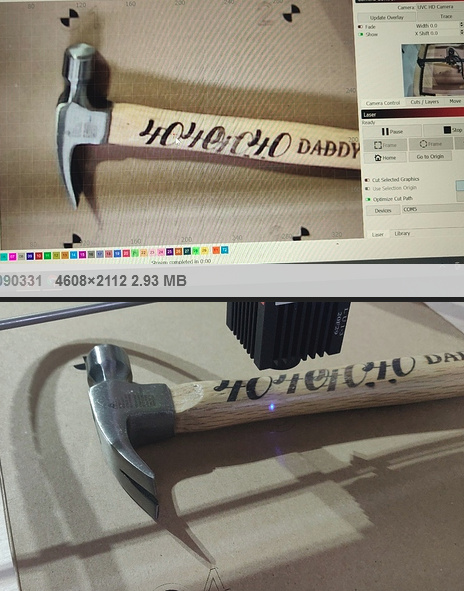

This is roughly where I had it the strange thing is it will go to all four targets and the center circle but if I place any object it won’t go

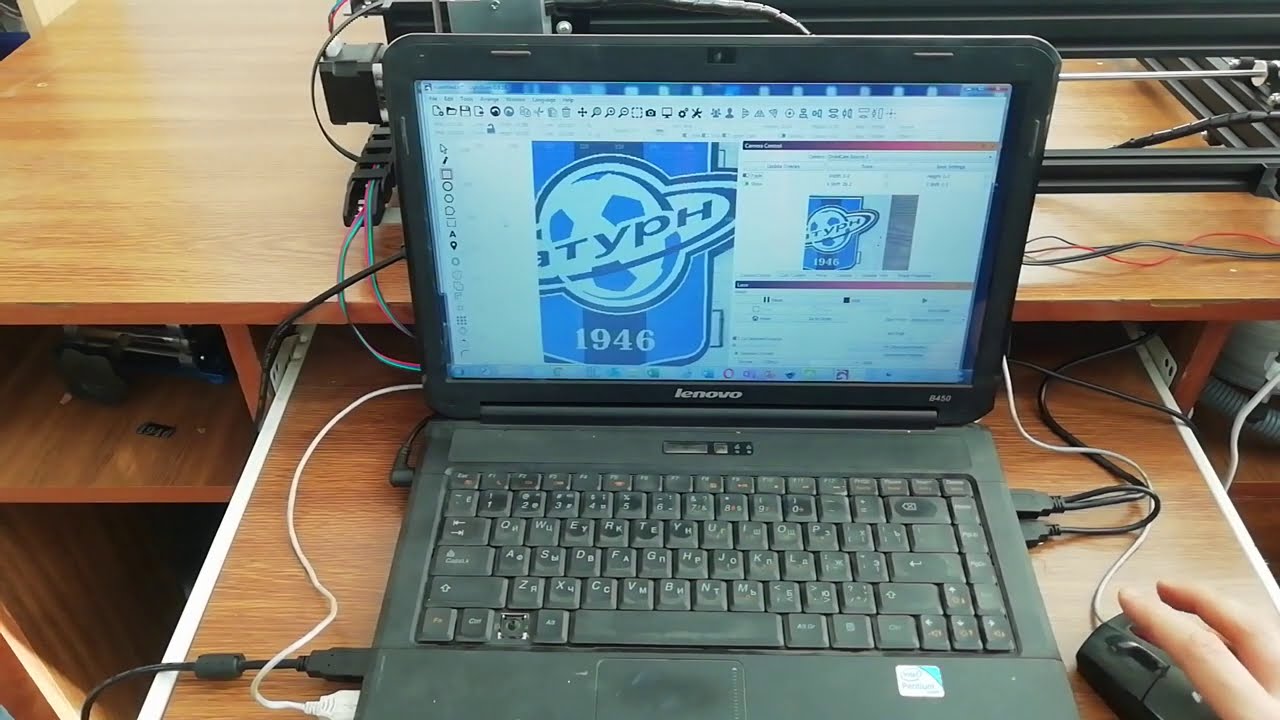

I have an idea that the camera should be aligned at the height of the work … You have the alignment on the table, but the engraving plane is much higher …

But it has. You just illustrated that when you place your hammer on the bed, the distance from the ToM of the hammer is shorter than what you calibrated the camera to (the ToM of your bed).

I was thinking about that but then won’t that defeat the purpose of having a camera, where every time you put in a new material you have to reprogram the camera

I thought with the camera you set it up and then when you add your work piece you take the picture and do your work on top of it

The camera should be installed in a manner that maintains constant distance to the ToM. In many installations, this is accomplished by having an adjustable Z on the bed.

Thank you I just thought I saw people using it with this machine and no bed

That is possible if you calibrate the camera to a specific material height and use primarily that material. Also, you can install the camera on the same plane used for focusing. If this is not your bed, then perhaps it is your laser.

Keep in mind that any (even the slightest movement) in the camera mount will affect the accuracy in the calibration.

You have to do the alignment marks at the same distance from the camera as the item you are engraving. The camera alignment is only accurate for the height that the markers were done at. The system is designed to work with a laser that has a Z bed that raises and lowers, so the top of the material is always the same distance from the camera.

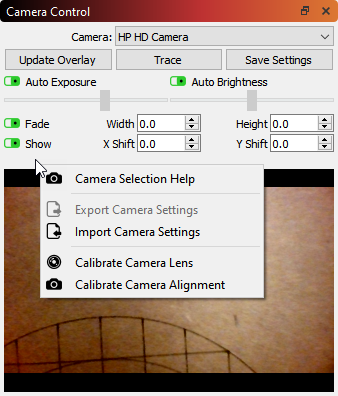

It is possible to run the alignment marks on a piece of material that is lifted to a specific height, then save that calibration by right-clicking in the Camera Control window and saving it with the height in the name. If you use 3mm, 6mm, 9mm, 12mm material, you can just save one alignment for each height and then Import the correct one when changing material thickness.

Thank you so much I’ll do that

Hi can you send me some screenshots if it’s possible. I still can’t figure out how to save different thicknesses.

Thank you in advance

Right Click in the camera control window and you can export / import camera settings:

Do an alignment at a given height, and save that with the height in the name. The next time you want to use the camera with material at that height, import it.

looking at the pics… it looks like your burn is spot on ! what I mean is with the camera looking at the hammer AT AN ANGLE… if you execute your burn directly on the calibration surface…then laid the hammer where you wanted to burn directly on top and aligned with that surface burn… then burned the handle… the burn would HIGH of center line on the handle. BUT in your camera view…the hammer would appear low of center where you burned on the surface.

clear as mud right?

I had this type of issue…hence a new box build with my camera dead center above the middle of my burn surface. BUT that same type of ‘thickness’ create visual error grows as you move out from dead center.

ptegler

ptegler