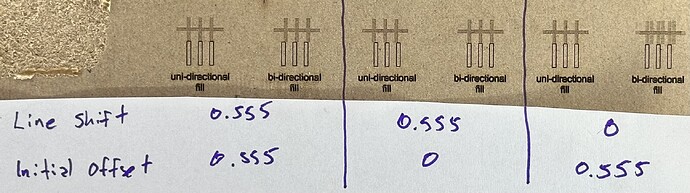

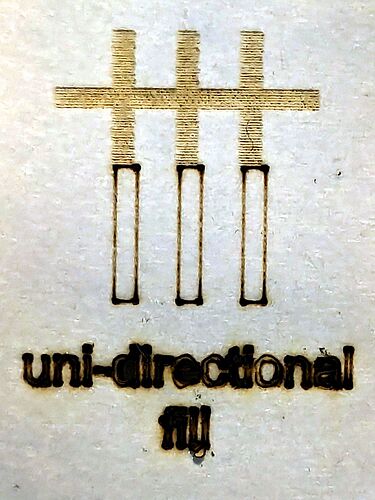

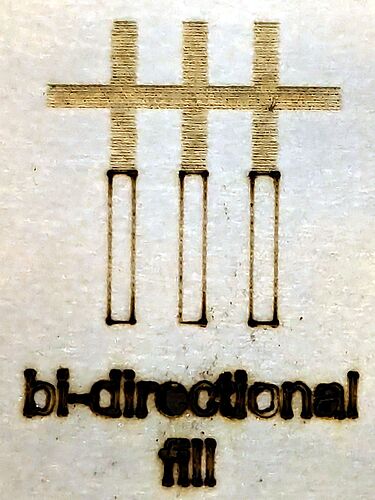

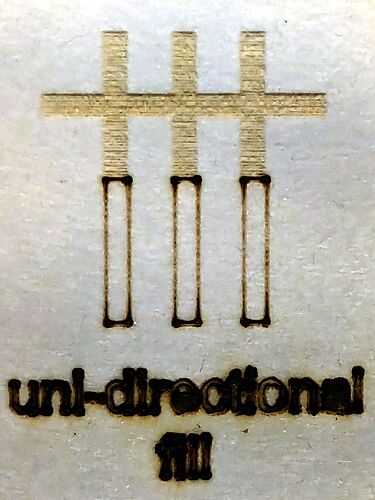

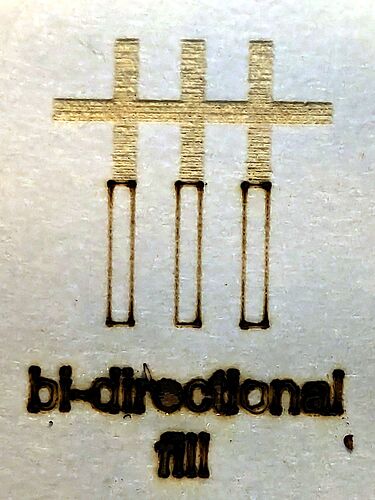

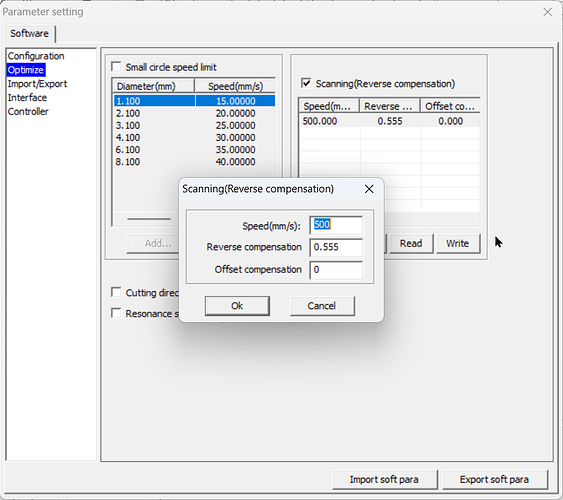

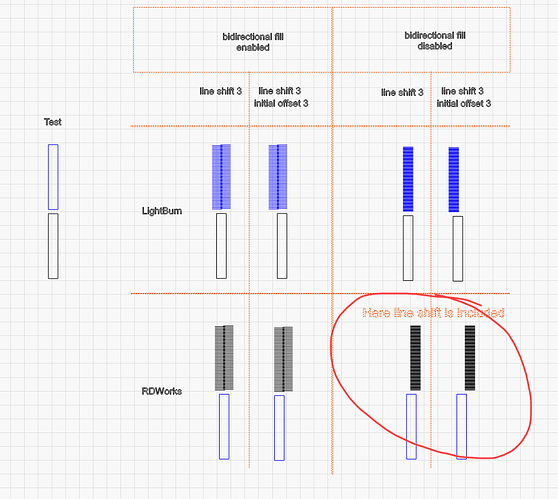

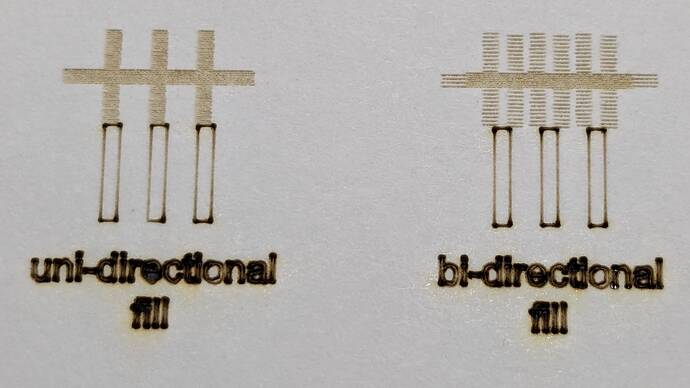

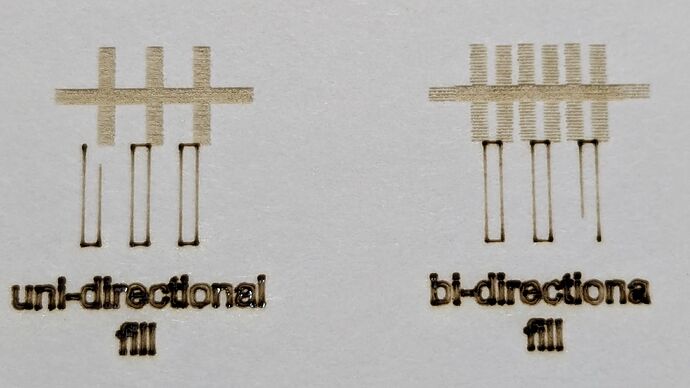

I am able to use Scanning Offset Adjustment | Line Shift to make bi-directional fills perfect, both in terms of alternate line alignment and also alignment with other work (like lines). Alternatively, I can use Scanning Offset Adjustment | Initial Offset to make non-bi-directional fills aligned with other work (like lines). However, there is no combination of Scanning Offset Adjustments that will work for both at the same time (having a layer with bi-directional fill and a layer with non-bi-directional fill, all looking correct and aligned with other works like lines). If I have values for both Line Shift and Initial Offset then bi-directional fills are not aligned with other work; if I have only Line Shift then non-bi-directional fills are not positioned correctly, and if I have only Initial Offset then bi-directional fills are of course not correct.

Am I missing something, or is this a bug? In searching the forum, I found this from 5 years ago which seems related: Scanning offset adjustment seeming to not apply when bi-directional fill is off

OMTech AF2028-60 / Ruida KT332N DSP:23.01.14 / Lightburn 1.6.03