I am constantly having issues with my Koenig K1325 cutting wrong dimensions/tolerances when cutting multiple identical parts on the one sheet. Its randomized from sheet to sheet in terms of where it goes wrong. I have ensured sheets not moved, we have replaced belts, replaced sprockets and yet still getting random anomalies as if the software is sending the wrong sizing. Seems to make no difference between sending the drawing directly from the PC or sending it to the machine first.

This is a huge machine!!! ![]()

Generally, this leads to a mechanical problem.

In small machines, I usually advise reducing the speed to see if the problem is related to sudden movements. Sudden movements can cause these types of anomalies.

Is the type of error in the dimensions always the same or does it also vary? For example, is it always 1mm (0.04 inch) or does the error value vary?

After this happens, if you point the laser head at a specific point, will it go exactly to that point or will it be misaligned?

If this is a Ruida controller connected by USB, then that’s entirely likely.

While you can try various USB tweaks, the bottom-line advice is to use the controller’s Ethernet connection.

These discussions explore (in grisly detail) what to do for both Windows and Apple PCs:

Now, if it’s already using Ethernet, then other problems rear their ugly heads, but let’s rule out the obvious cause first. ![]()

I had no idea about that!

I always thought that if there was a faulty communication, it would cause an error in any type of machine. ![]()

It certainly will, but Ruida controllers seem to bring their very own heartache to the party. ![]()

USB was designed for “desktop” devices, not high-current machinery like lasers, and lacks the noise immunity required for “industrial” applications. That many of the controllers are, shall we say, under-engineered doesn’t help at all.

I’ll try not to forget! ![]()

I’m thankful for the clarification. ![]()

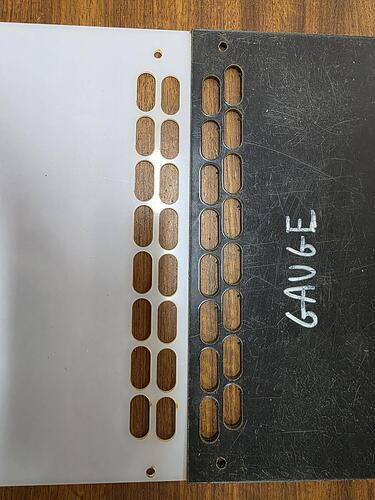

I have switched it over to ethernet and see if we get a different result. Thanks for the advice. Here are some misalignment examples - the external dimensions are all right as are the dimensions of the slot ID’s but their alignments are all wrong. Its strangely randomized - meaning cuts further into the sheet are right so it’s not like it’s all wrong from a certain point or that the material has moved.

Assuming the machine has a Ruida-flavored controller (what’s the model number?), this could be a perverse instance of the PWM Rising Edge Valid mis-configuration:

It usually affects the alignment of engravings w.r.t. vectors, but can clobber pure vector layouts: