Hi. I have an Emblaser 2 and have downloaded lightburn but it goes straight to the work space and won’t give me options to put in my liscences key or choose my laser. Please help.

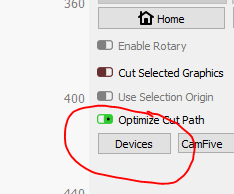

Go to Help/License Management and you can enter your license details. You can click on the “Devices” button on the laser tab on the right side of the screen to get to the device add wizard as well.

Most likely you’ve set it up at some point before, possibly with the trial. For the license, go to Help > License Management and you should be able to enter the key there.

Once you’ve done so, click the ‘Devices’ button at the bottom right, delete whatever device you have already set up, then re-start the software and it will prompt you to set up the Emblaser.

Hey thankyou both for the information. I got the machine working and it is engraving beautifully. However I cannot seem to get it to cut. Can you tell me what I may need to do setting wise to make it cut. cheers.

When you want to cut something, setting a layer to ‘Line’ will tell the laser to follow the path of you vector art. Setting the appropriate speed and power will be based on what you are wanting to cut. Your settings for cutting paper would be different than those used for cutting wood.

Cutting with a diode laser is slow going, and usually takes multiple passes, and air assist. You haven’t said what you’re trying to cut, so I can’t be any more specific than that.

Thanks Oz. At the moment I am just trying to cut a sample out of 3 mm balsa wood but my main cutting will be from 4 to 5mm plywwod. I just want to make sure I have the setting right but cant seem to find any exact info in it. Just trial and error I guess. Cheers.

4 and 5mm plywood is going to be VERY difficult to cut with a diode laser. Have you considered buying a CO2 laser, which would be the right tool for the job?

Oh wow really. I cant afford another laser. I bought this because I specifically thought it was able to do that. Bugger.

I regularly read here in the forum that there are some people who can cut 3mm plywood with a diode laser. I’ve also been able to cut plywood but with 10-30 turns with my 5.5 diode laser. This result was not usable. Today I use a K40 and there are still once in between plywood (3-4mm) which cannot be cut properly. Try searching the topic here in the forum, you might benefit from the experiences of others.

If you have air assist it will make things go much faster. Still slow, but it will work:

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.