UGHHHH I am so frustrated! I have literally tried every setting and can’t get my A5 pro to engrave brass or steel plate. What settings do I need to use? Power?

How are you attempting to do this? Normally blue diode lasers would not be able to mark brass or steel.

I’m currently using the setting in laser Grbl for brass. 100% power at 15mm pass. It’s not working at all. Absolutely nothing. The metal isn’t even getting hot. I thought the A5 pro could

Etch metal but I can’t find the settings to use to make it work

This is a post from @Rick in 2021, I do not believe this situation has changed for diode lasers

Cutting or marking metal with this diode laser is not possible. You can paint a product (several to choose from) onto the surface, then when lasered, a chemical reaction bonds this paint to the metal. You can also remove the finish from a metal surface, such as anodized aluminum or the paint one finds on Stainless-Steel water/coffee containers (think Yeti - https://www.yeti.com/en_US/drinkware or La Tazza Drinkware - https://www.latazzadrinkware.com/ ).

Are you using mm/m?

The advertisement says metal but it only shows them cut 0.05mm Stainless.

@berainlb has a good point about visible light lasers not working too well with metals.

With copper, you may not be able to do much.

I don’t use my led types for this, but I have a fiber and engraving copper has a lot of issues that effect how it’s engraved

Copper has a higher melting point, according to the Internet on lasing metals. It also is one the of the most heat conductive metals we have… makes it great for cooking… but not so great for lasers.

On the fiber I have to make big changes to get much of an effect…

Dropping the speed is about all you can do if you’re at 100% power.

I’d drop a note to the vendor and ask them.

![]()

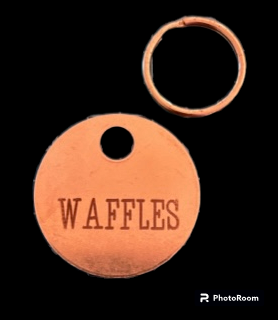

I’m not sure. It’s the setting suggested by laser Grbl/ atomstack. I did probably 15 passes and nothing. What kind of laser do I need to do metal engraving? I wanted to make tags for my dogs

A fiber laser is what you will need to successfully engrave metal, however they are not cheap !

Fiber lasers are generally for man made materials and co2 for natural. Of course there is some overlap…

You probably need a fiber I’ve also heard some uv lasers work, but have no experience with them.

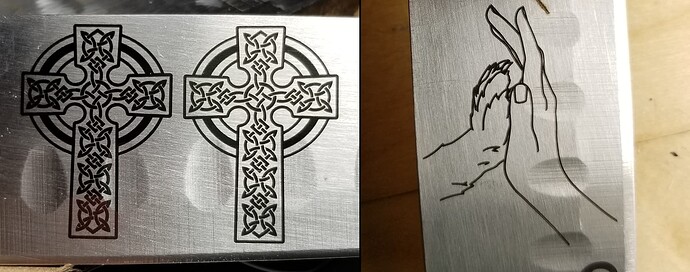

I’d say a fiber is the best bet, but also the most expensive. these were done on a fiber… they are all annealing marks, not engraving. You can’t feel the mark with your finger.

These are a couple of cheap dollar store kitchen knives…

How deep are your pockets?

There are anodized dog tags and you should be able to removed the anodized layer with your laser.

They are low cost and my be worth trying a few pieces.

![]()

I’ll add few more options in case a fiber laser is not a viable option:

- There are IR laser modules that you can buy that can mark metals. xTool offer such a module and Atomstack offer the R30 that I believe works similarly.

- There are techniques involving using sprays or other materials to pretreat the material that allow you to mark metal. Cermark and Laserbond are some examples but there are many other similar products.

I’ve got a NEJE 40630 laser and I could never get LBT100 to work with it. I asked the factory people and they don’t recommend it for led types.

Most of these coatings are not low cost. This is it from Amazon, and another version, Brilliance laser marking, along with OMTech version.

I’ve used it successfully with glass on the fiber…

As these get more powerful, maybe it could be a good option.

![]()

From what I have seen success for the marking sprays is a function of the following:

- material itself. Stainless seems to have the most success

- strength of diode laser. The higher the better. Many diodes can mark stainless even without the spray

- bonding spray brand. It seems not all sprays work equally well under all circumstances. But I’ve seen enough examples of this working not to dismiss it.

Ok I know with a 5.5 watt laser I can’t engrave S/S (stainless steel), but I can mark it, that can’t be removed with a brass wire brush.

I used PVA Glue and a bit of laser toner.

on the other one I used Meths and a bit of Toner. (Meths = Methylated Spirits)

Meths is Denatured alcohol in NZ.

Edit: My conclusion is the PVA is ok and is hard to remove the Meths is easy to remove but you have to be careful after it is applied that you don’t touch the surface cause it is easy to come off.

The PVA was applied with a sponge brush but I used the stirring ice lolly stick to spread the meths and toner the brush was removing the toner making it hard to apply a second coat, have to try a spray next time…

This is similar to using TiO2 and PVA… The laser heats the TiO2 and binds it to the material…

You’re using laser toner to bind to the material…

The pva I use washes off pretty easily… is it water soluble?

Have you tried it on glass?

![]()

Jack…I have not tried it on glass (weather here in NZ is crap) when I get a chance will try glass, tile also, the PVA I use is water soluble but I found it hard to remove !!!

How much to TiO2 do you use…

I have access to more toner and it’s color (what’s the chance of it working).

Will keep you updated later in the week…

![]()

Here is a link

Acrylic mix with TiO2…

Both are kind of long…

Sorry about the weather there ![]()

![]()

I used the xtool infrared laser. speed 4mm/s power 90%. no etching compound needed, I just cleaned it with alcohol first, it came out quite nice and was a nice engraving in the brass. customer was very pleased.

Hi Jack, I use Rust Oleum Black Flat Protective Enamel on glass with my 20 w xtool laser and it works very well. Easy clean up with hot water and if the surface feels too rough hit it with some 220 wet/dry sand paper. Customer loves it.

speed 100 mm/sec power 80%

Hi Jack, I use Rust Oleum White Gloss Protective Enamel on tile with my 20 w xtool laser and it works very well. Easy clean up with hot water. This was just a test, one of many lol.

speed 15 mm/sec power 100%

The paint on tile is the original Norton Tile Method (NTM) that you read about… Heat causes the molecular bonding of the TiO2 to the glass… It works on other materials also…

What most of us don’t like is dealing with solvents to remove the unwanted paint after lasing. A lot of us have tried to use water or other non-volitile or toxic types of coatings to try this without the problems of solvents…

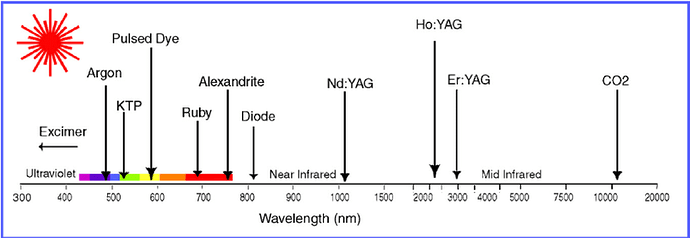

My co2 and my fiber both reside within the IR region… this is very broad… the co2 will not work on metals without a coating, but the fiber has no problem… Both are IR, but the fiber frequency is 100 times the frequency of the co2.

Yours and most are diode-pumped solid-state laser (DPSSL) lasers that are basic Nd:YAG types… with an output around 1064nM.

You can see Nd:YAG frequency on the chart compared to co2.

Most of the ss led types I’ve seen in the ir spectrum are in the 1064nm frequency, which is similar to the fiber.

Nice work, thanks for posting…

@Bulldog does magical work with these… he’s using a fiber, but it’s the same frequency as your ir… he’s got a bit more power available… but you should eyeball his work…

Have fun

![]()