Hi everyone ! hope I can get some advice. I’m using LightBurn software with Neje Master 2S with N46030, 30watt engraver. I’m trying to do engraving on Tiles and appreciate if anyone can recommend settings on LightBurn. From what I see in Youtube there are different recommendations for different engraver. Appreciate and suggestions etc.

Thank you.

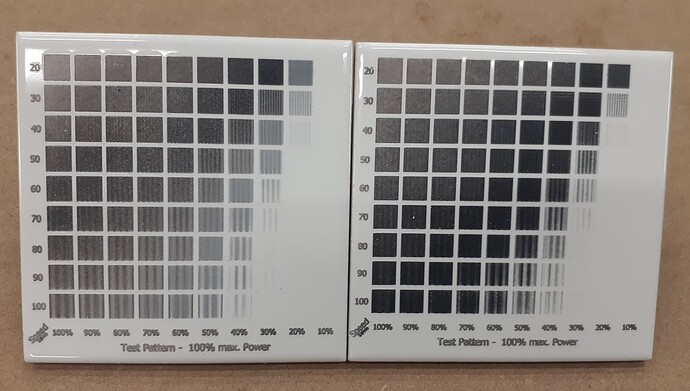

The first thing you should do is a test tile.

This will tell you the best setting for your particular laser.

Was this from ‘Laser Tools → Materials test’.?

This one is nice also,

https://www.o2creative.co.nz/laser/lightburn_basic_generator.php

Good luck

![]()

Yes, Its basically the same thing.

I just modified it a bit.

I moved your thread into the Unofficial channel and tagged it with a few of the topics to get a little more information for you. The test tile is a very beneficial step.

Dear Jack

Thank you for your reply and recommendation. Been a great help . I will test it out over the weekend.

John Ng

Hi Jack Thank you for your reply and advice. I log in to the website you gave to check

Lightburn PowerScale Generator - O2 Creative and it’s quite interesting. I’m not one of those specialised computer user and notice that in the website it indicate using something similar with Photoshop. It also work with LightBurn. Can you advice which one is the correct software in case I decide to order one.

Thank you and take care.

John Ng

What software you chose to use is up to you.

Photoshop, isn’t available for me, one is that I run Linux and don’t think they’ve ported it and two, I generally only pay for software I use, like gimp. Gimp is an open source image program similar to Photoshop.

I use gimp, but it’s abilities far exceed my abilities to drive it.

If you use package A a lot in other things, it might be frustrating to learn program B that does the same thing in a different way. Would you recommend a box end, open end or crescent to loosen the bolt? Depends on what you want to do and what you have on hand many times.

If you can create something in one of the Lightburn importable formats, it’s always best.

I generally use Lightburn for many of my designs. When I build something that the dimensions could change, I will draw it up in Freecad using parametric parameters. I can change a dimension and Freecad will ‘generate’ a new dxf file that I can import into Lightburn.

No easy choices. The OS, personal choice, what you wish to do and cost.

Good luck

![]()

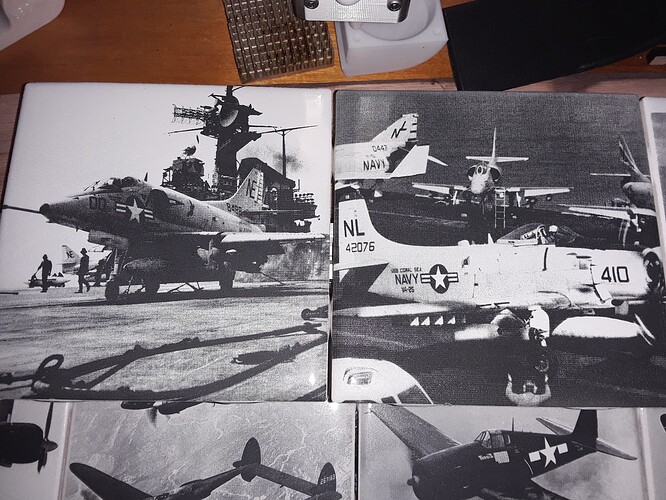

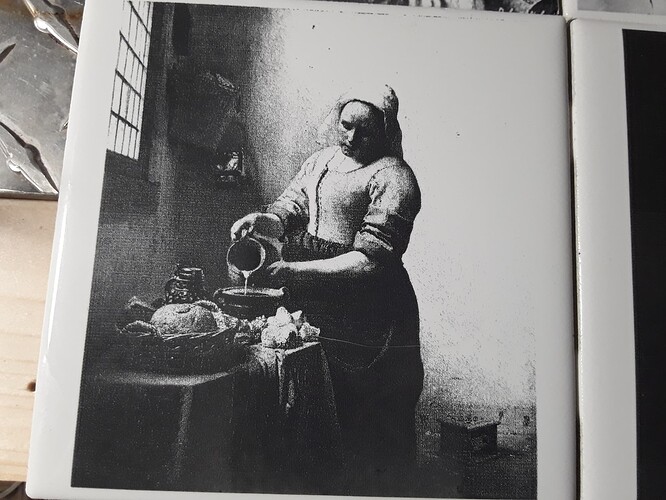

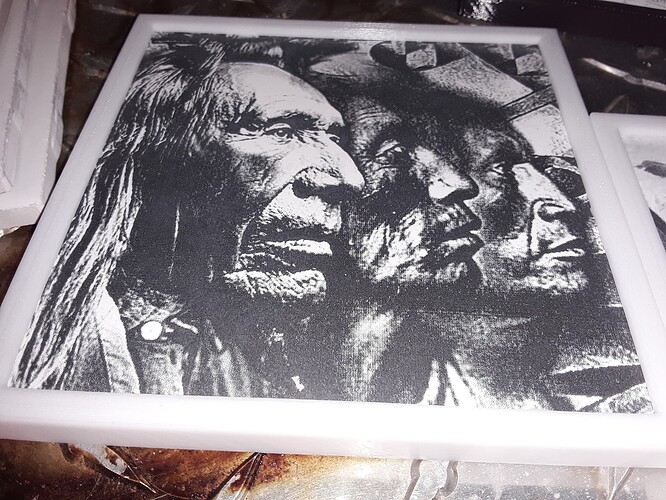

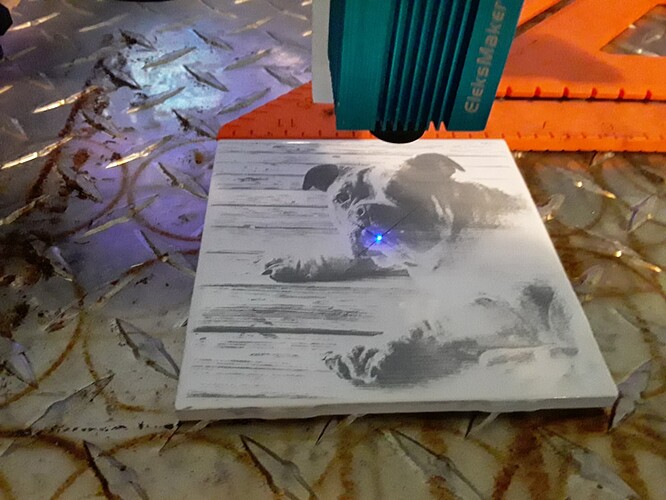

I had occasion recently to laser a couple of tiles for a house-warming gift…

They turned out so well I decided to do a few more of the series I’d downloaded…

I used the Norton White Tile (NWT) Method… which leaves a permanent fused-in image that can’t be scraped or scratched off. It’s’ the TiO2 in the flat white paint (Krylon ColorMaxx Paint+Primer works well) and the laser that do the “magic”. The NWT process is simple and uses tile, paint, and acetone (or thinner). Please be aware there are folks pushing other lasered tile methods which are not NWT and do not leave a permanent fused image (just engraved paint, clear-coated over). Just saying…

I first clean the tiles with acetone and then spray tiles with a light coat of paint (allow to dry for at least a couple of hours)…

and then laser the image onto the tile. Here I’m using a little VigoTec cantilevered laser engraver with an Eleksmaker 2.3W laser and my printed Z-adjuster… running at 1500 mm/min and 90% power (determined from the test tile in the 2nd photo). All “photo processing” was done within Lightburn… 339 dpi and Jarvis dither…

and then clean off all paint/residue with acetone. Finally, I just wash the tiles, as you would a dinner plate, and allow to dry. Get the recipe about right and you’re left with these…

or maybe these…

or these…

or possibly these…

Get your 3d-printer involved making frames… and possibly laser-cut a photo stand to display your work. It’s a pretty easy process and great fun for pretty decent results IMHO… ![]()

– David

It looks great.

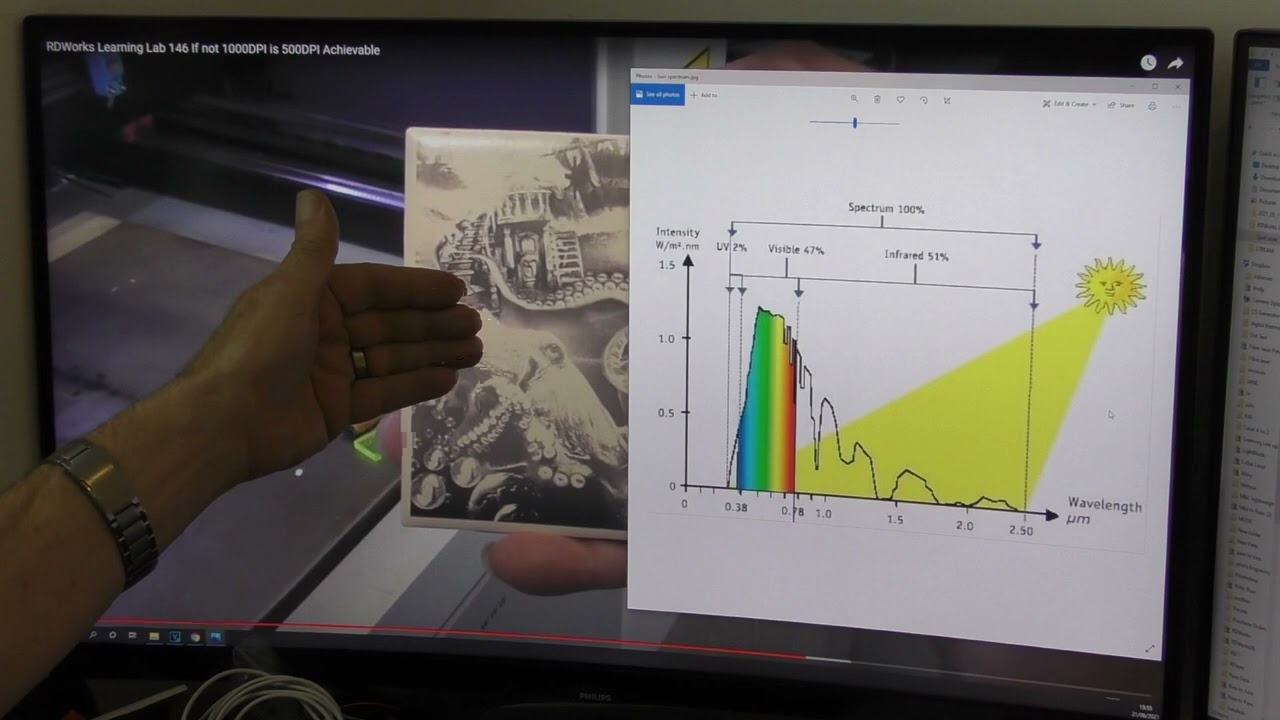

Russ Sadler has a few videos that you might like.

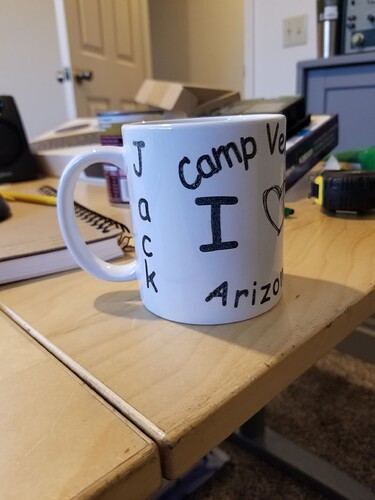

I did a mug just playing around. No real graphics…

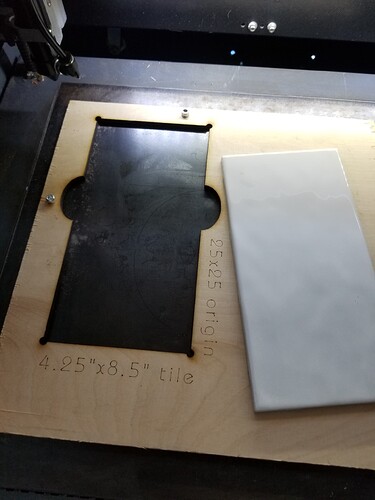

I do have a jig for some tiles, but haven’t spent any time to see what I can do with it…

Have you tried something like a table or wall… putting together multiple tiles for a complete image?

Looks like the quality is there. I think it would be beautiful…IMHO…

Thanks for the detail, I can use it…

![]()

Thanks for the kind words, Jack.

I love all of Russ’ stuff… but for tiles like this I’m pretty much following @Bulldog’s NWT recipe. TBH I’ve been in a weird funk/malaise for most of the past year and haven’t been nearly as active in my hobbies. The house-warming gift kinda gave me a kick in the pants to start playing again… and I’m enjoying getting back to doing something useful again.

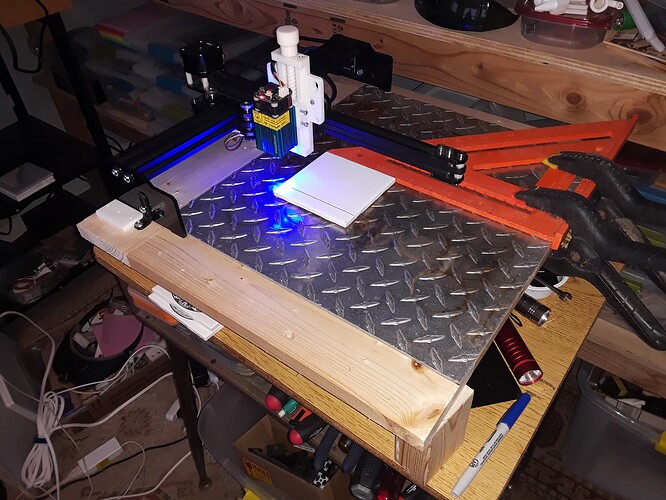

My “jig” for these tiles is simply the orange square clamped to my worksurface… and a junk tile with the center cross-marked. I align the upper-left corner of the junk tile with the tip of the square and manually move the laser to the cross. Then I remove the junk tile and replace it with a freshly-painted one, ready to go. All my gcode files (generated in LightBurn) have the center origin so everything lines up nicely…

I do have a rotary fixture for this same machine (under the diamond-plate) but haven’t played with it enough yet to do anything useful. Probably ought to start though…

I’ve thought of a panel or table top of display tiles… and I think @Bulldog has displayed a bunch of his work that way. The multi-tile image on a backsplash or in a bathroom would look cool as well.

Sadly, at 75+ years, I’m really slowing down physically and can’t/don’t do much in the way of woodworking anymore. I’m a retired EE and CNC hobbyist/builder as well… but, historically, I’ve always gotten a bigger kick out of building and playing with the machines themselves rather than using them to produce anything useful. And, since I have little/no desire to make/sell stuff… not surprisingly, I live alone in my clutter… ![]()

Thanks again, Jack, for the response and kind words.

– David

I’ve been trying to use NWT on an RF-CO2 and DC-CO2. I’m having trouble in that I get no mark, or I burn off the paint and end up punching a similar hole through the white surface that I’d get anyways with no paint, except there’s a black halo AROUND the hole. This isn’t yielding a quality image.

I’m not sure what change to make. Lowering the laser power to something much much smaller and going slower presents a problem for the DC-excited CO2 tube at least, because they don’t lase consistently on the low end of wattage output.

I use a 2.3W diode laser to do the ceramic tile engravings. I have more powerful diode lasers and a 50W CO2 laser… and they simply do not get the quality result I get with the 2.3W Eleksmaker laser. The process can be “overpowered” so easily that a few speed/power grid tests are pretty much vital to determine the best speed and power to use for a given material and laser.

@Bulldog (Nicky Norton) is the authority on the NWT method. He is a denizen here and he’s left his recipes in numerous places. I’d recommend this particular one to study closely as it gives tips and instruction for both CO2 and diode lasers…

I know there are a few folks getting decent results with higher powered diode and CO2 lasers… hopefully one of them will chime in and be able to help. Good luck.

– David

Sounds like the problem! I had suspected this.

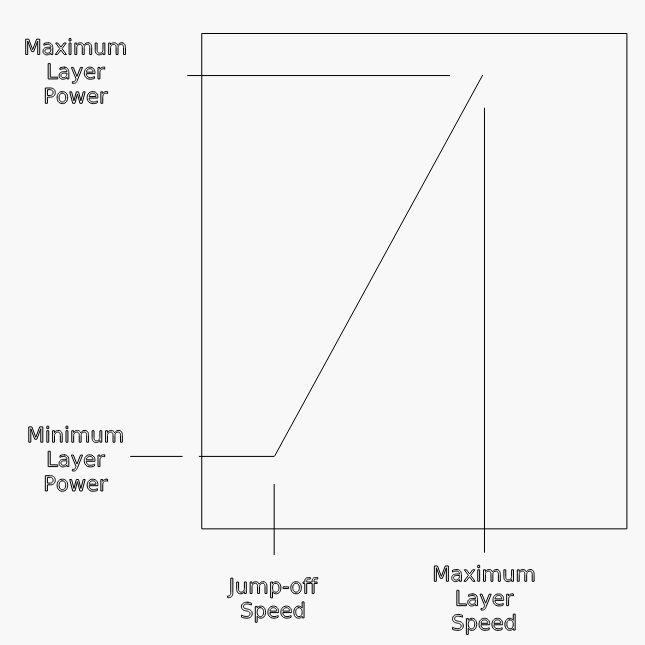

Ruida has a “start speed”, and while it technically can be set to 1mm/sec, it will add inexplicable random unrelated bugginess if you go below 5mm/s. You cannot set it to 0. You can’t ever set it to 0.5mm/sec (30 mm/min). When the head is going below the start speed, it uses Min Power. Even if it’s not due to acceleration limits at that instant but rather the Layer asked for a lower speed intentionally.

15% power may be difficult to get most lasers down to in an orderly fashion. They become less stable. There’s no good way to get a 100W DC-excited CO2 tube to produce, say, 10W. It’s a steep slope of output power vs duty in this area, and inconsistent. You can come up with an exact, say 12% to get 10W, but then 11% is no beam at all and 13% is 15W, and the power you get at 12% varies, sometimes giving 15W and sometimes no-beam.

So, a Ruida’s start speed can be a problem. And the larger the DC-CO2 laser would be, the less stable it is trying to get something like 10W output

Thank you Jack. Will play with it again over the weekend. This is my hobby and I use Laser engraving mainly for my leather work which is also a hobby but specialised now. Out of curiosity I’ve been going through Youtube to watch how to do engraving on Tiles and its interesting.

Thank you John Ng

Dear Danny. Thank you for your reply. Will definitely go through it to learn more.

Be Regards

John Ng

I think you’re referring to the ‘jumpoff’ speed. The start speed is how fast that axes initially starts, at least that’s my understanding.

![]()

Other way around. Jumpoff speed is a weird choice to not use acceleration rules at first and just go directly to stepping at that rate. Start speed is where it only uses min power until it gets past that

I use the jump-off speed and it seems to work… This is from the Thunder laser

x Start Speed, y Start Speed: Off scanning speed in the use of stepper motor drag, do not

began to accelerate from 0, but can start work directly from a speed…

The ‘jump-off’ speed is not very clear either…

Strange beast…

![]()

I did some more testing last night. I’ve got over 200W of RF-CO2 here. I got it to “kinda” work but only when the speed in absurdly slow, like 10mm/s.

The laser can throttle down to pretty low power and still produce stable output, but Ruida doesn’t like any of these parameters. Ruida’s lowest possible start speed is 1mm/s, and power too. Oddly, 1.5mm/s just “broke” Ruida and inexplicably turned the output into dashes that made no sense and this didn’t happen at 2mm/s.

At only a few points did I get burns where it turned the primer into black glass that sat in the burn spots. Turning off air assist made the black glass easier to create.

Otherwise, all too easy to overpower and blast off the primer, resulting in just a white glassy spot on the tile, or slightly gray, or a hole that drills deep into the tile, also with the primer lost.

In lots of cases, I can get white glass at the burn point, but a black halo around it. Usually that black halo comes off with the primer removal, too. Or other times I get a sooty black in the dots that washes off. Or sometimes a light infusion of black into the glass that just makes a gray.

But I did see some points where it’s making glassified black spots.