Do as well ## in console and output

And if you are unable to reply here

Support@ortur3dprinter.com

WOnt reply as fast as is near midnight but will follow up asap

I think however thee might be something weird going on.

IN absolute settings try putting the job at the very center of the machine grid. see if no errors there

Not anymore. ![]() I have bumped your access level, you should be fine now.

I have bumped your access level, you should be fine now.

Ok I filmed video of homing but I dont think can upload videos on here. I mean it looks pretty. normal to me

Try to do anything in the error state will give you a number 9.

To send ANY command to the grbl controller it must be in the ‘idle’ state.

So it’s flame error caused it to go into an error state. It will stay there until you do what is says, I use $X

If you have to, put it on your google drive… if you have access. Right click, set protection to allow anyone with link . Click copy link. Paste it here.

I’m all set. Not willing to do that. I’ll survive not being able to use final half centimeter of available space I don’t need the full 400mm anyway. And I tried that $X first thing I tried unless you’re saying I did it wrong whatever. I got this to use not to stress out about details on forum. I dont care to do all these commands and stuff. If its not working simply it’s not for me

I was going to start new topic but I’ll just ask here in case quick. How do I fix this? Like leading lines into straight square cut… Not sure what this is doing or why is doing this with default settings

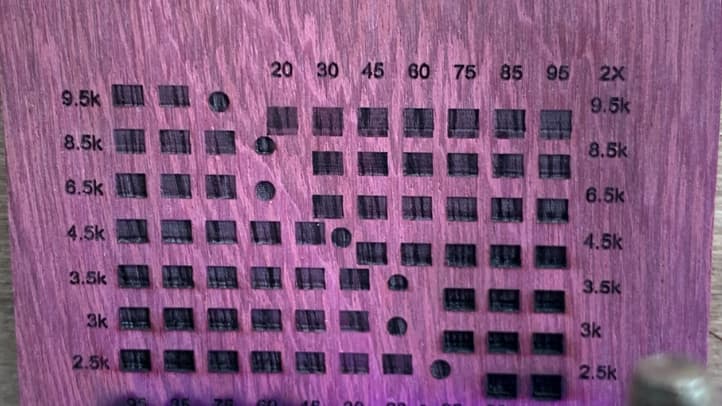

Additionally is there way to fix this other crap where laser is much more narrow/stronger in one direction than other. Like slow down x direction more or something… again its not subtle and seems odd to release product like this in my opinion. This is back side

Virtually no machine will give you the complete limits. If the head is moving it needs to slow down and stop before it can change directions. You have some control by slowing the speed down so it takes less space to turn around and get back to speed.

You can get to the edge on one side and travel parallel to it. But if you want to run the 400mm at a certain speed, you can’t. That’s physics.

Grbl controllers usually have some type of overscan setting. Did you check that?

Additionally it appears to be cutting deeper on the side of the. square it begins on. Is the power fading? Is it catching residual laser from nearby stuff.

I’m not sure what I’m looking at.

I believe the extra line occured prior to drawing the square and thus the physics analogy would not work it just starts the laser too soon as it flies over to it and continuously moves into cut. If it needs to slow down and stop before proceeding into square makes sense to me and also seems like should be default. Disclaimer I do get grumpy when things I think should be simple become overly complicated more than I prefer but I do appriciate all the help

A filled square. Uh idk what how else to describe it. the depth is more in the begining (right side, which is bottom the photo is just sideways)

Furthermore not sure why its cutting like this. Nothing bumped it and cuts following this were in their correct spot…

Was for you complaining you can’t use the whole 400mm. ![]()

I can’t see what’s happening in the photo or where the actual issue is. Is the the coloration around the cut or can you physically see the depth?

If this is your first laser, you have lots information to assimilate. Probably the first is these machines are not like a cell phone a 2 year old should or can drive. It’s a steep learning curve, especially when there is something that doesn’t seem to function properly. Most of the time it’s the operator. That’s only because they don’t know yet…

Best thing for you is to sit down with a coffee or whatever you relax with, think about the problem and how to present it to the people trying to help you. Sometimes it just ‘dawns’ on you without the help just thinking about what’s happening.

Wanna be beat by a pile of junk? Don’t take that from it, show it whose the boss. We’ll help you figure it out.

You might want to try and describe there and what you are seeing that isn’t right.

Take care ![]()

K I was not reffering to the edge thing for “physics” i was over that and talking about the 3 new problems I had with descriptions and pictures. To which i am no further to understanding the issues. That is

-

Leading laser cut prior to defined square.

-

Cutting deeper in the first row of cutting and stair-stepping up all for a constant level

-

Entire sets of squares being cut at a different slightly lower position than defined.

-

Laser is much wider than is tall and therefore cuts much stronger in one direction than other

I have had experience with plenty of larger lasers not owned by me as well as 3d printers i have owned the cr-10S which i spent 99% of my time tinkering and 1% cutting. Laser is about 10x less complex than a 3d printer and its been 2 years newer and this is latest tech. Just because it is your precedent to expect constant tinkering it it not mine. It is 2021 I’m not being crazy to have bought this and expected more plug and play. I dont care if you think your getting better than me by being sly and claiming physics on me complaining. Im well aware of physics as far as going into edge space other person seemed to indicate something else was wrong for whatever reason. You frankly have added nothing to any of these problems which is fine its not your job to and im not expecting any answers they are only bonuses and appreciated.

As for being “beat by junk” lol its not my motivation to stress out over this. The smart thing is to return it and work on one of my 10 other hobbies…with that said I do think some of these issues are not rocket science and I only or possibly with help here may be able to figure out but I am unlikely to elect to spend days on end tinkering just for a hobby.

Sorry, but that’s what is sounded like. I think they are about as complex. Instead of a print head you have smoke and mirrors ![]()

I’m afraid these are tinkering machines.

Have you seen the Glowforge? Lots of ‘less tinkering’.

I take full responsibility for assuming it was going be significantly less tinkering but helpful to know that is still the state of things in 2021 and I will give the noted 4 problems above another couple days to see if I can resolve and a few days to think more and decide weather to keep or not. If anybody has any suggestions regarding the 4 problems listed above that would be helpful. Maybe I’ll look at that glowforge but tbh I’m not dying to use this it was more to build joyfully build a few projects I had in mind and I’ll probably not start a jjourney with another machine. Key word joyfully lol. But yeah I think this one is one of best on market so want to give a chance still

I mentioned the glowforge, it’s an US sold CO2 that is very pricey, but it’s sold as an out of the box usable machine. It has drawback other than price.

I think you’ll do fine with your background. The only difference between a 3d printer, laser or cake icing machines is the ‘tool’ is different. X and Y coordinates control is the same and you can complicate it by adding another axes, but the basic design is the same.

It might seem that a beam of light wouldn’t be an issue but there are many things that influence a lasers beam. It’s more clear with a CO2 type as it’s a ‘bigger’ view. Both generate a coherent beam of emf at a specific frequency. This light has to be gotten to the head, if it’s generated there, OK, if not it passes through mirrors (or fiber) to get there. The lens and focus is where the heart of the power come from. The ‘power density’ of a beam is high, but a beam is about 6mm (CO2) when you focus it down to a tenth of a mm, you get a real high power density. That’s what does the work. The focal length of the lens also determines how fine of a focal point you get and how ‘long’ that focused beam is.

A short focal length has a shallow focus area, where the long lenses have more ‘depth of field’. The 2" lens I have cuts thicker material at the same rate than my 1.5" lens.

They may seem simple, but there’s a lot more there than meets the eye.

Take care, good luck

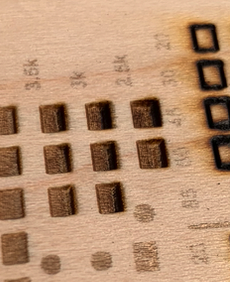

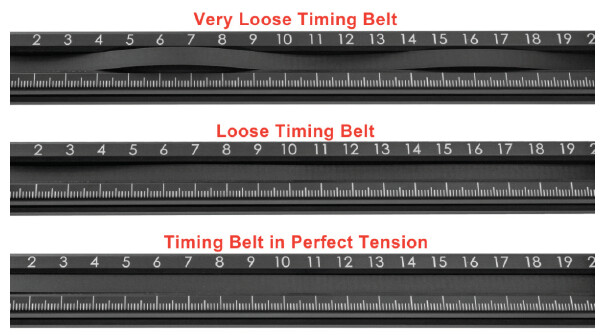

You seem to be having belt tension issues

Could you please take images of your belts while machine is iddle?

Specially on the Y (left and right belts)

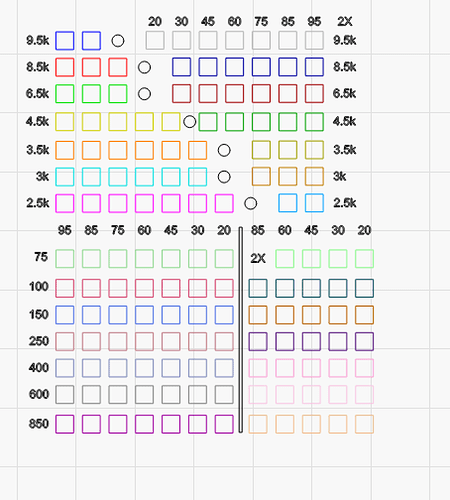

Exagerated representation

The glowforge machines do appear to be pretty reputable and reliable based on first impressions. May look into that more seriously. Thanks! (I also did not realize how significant the fumes would be but it does seem like these ortur style may unusable indoors for cutting which is an issue