You may only have half that Lead-screw length available to you depending on how the Z axis is supported.

The first thing I’d recommend is reducing the speed and acceleration of the Z axis. We’ll start with the Motion Settings:

In the Console window in LightBurn please type the following in preparation for calibration:

$112=1000

$122=100

Press Enter after each command. These aren’t written in stone - they’re an educated guess at best.

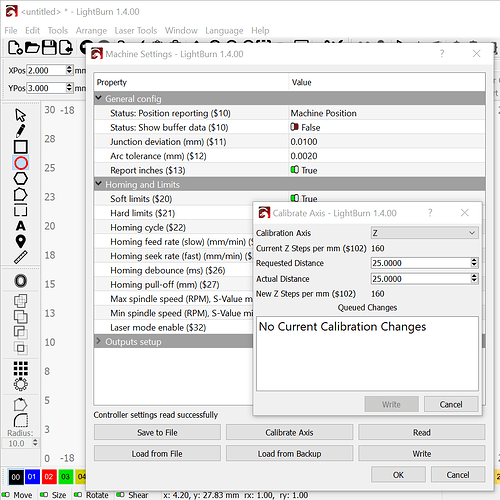

Calibration for the Z-axis (steps per mm) is shown for $102.

Would you be willing to fasten a scribe or an awl to the engrave head that it points horizontally? It doesn’t have to be perfect or dead level, It just needs to hold its position to make half a dozen marks. You’ll get great calibration data doing this with a sharp marking tool - it will outperform a felt pen by a considerable amount. It’s also much safer than turning the laser sideways.

In the jog window in LightBurn, lower the engrave head and confirm that the up-down arrows are behaving correctly. Make a mark on something cheap and recyclable with the scribe attached to the engrave head. I’d use an aluminum can or coffee can, a piece of scrap is fine as long as it’s repeatable.

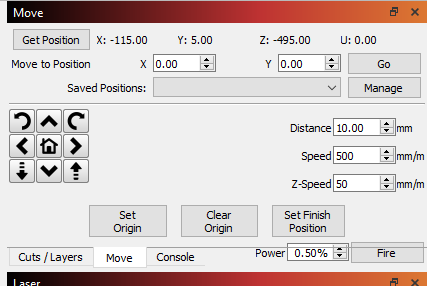

In the Move window set the distance to Jog upward 100mm.

After that one upward Jog command, scribe the selected object again.

Measure the distance between the two scribe lines (a Vernier or Dial Caliper would be a good choice).

If there is a substantial difference between the 100 mm Jog distance and the distance between the scribe-lines we can freehand the first adjustment by changing the ratio in $102.

You are also welcome to adjust this in the Machine Settings window in LightBurn:

Click Edit, click Machine Settings, click Calibrate Axis, and select Z for the Calibration Axis in the top box of the Calibrate Axis window.

Enter the Requested Distance (100mm) and the Actual (Measured) distance then press the Write button.

I would expect a first pass to be about 95% accurate.

Jog the engrave head back down - by the measured amount from last time. The measured amount will be closer to much we want the engraver to move now that the calibration is closer.

Mark the object with the scribe again, Jog upward 100mm in the move window and mark it again. Repeat this calibration process until you can no longer detect a difference between the Requested Distance of 100mm and the Measured / Actual distance.

Post measurements and observations as you go. It’ll be interesting for us to see how different the calibration is.