I have a new Gweike Cloud Pro 2 55w laser running lightburn 1.7.07. When i power the laser on, the axes home out just fine. When i press the home button in lightburn, it sends the axes to their “home positions” (if the head was elsewhere) but does not engage the switches and reset the home position. If the axes are already at their home position then nothing happens at all. This isn’t much of a problem until something happens that causes a motor to lose some steps and throw off the position. When that happens, and you press the home button, the axis that lost counts will slam into the home swith and sit there. You can jog off the switch and pressing home again will just slam into the switch again. The only choice seems to be power-cycling the laser so that it auto-homes.

I s the machine bed size set to 510 x 300 and homing at right rear, also the machine motor should not be loosing any steps i think that might cause it

Hello Keith and thank you for your reply. Yes, the bed size is set correctly. The lost steps are another problem that I didn’t address in my OP. For some reason, when I use the framing function, and the job is more than a few inches away from home, the X and Y axes stutter really bad while moving to position losing counts along the way. The framing ends up happening at the wrong location and when the head returns home, it stutters even more, and then it slams into the home switches. I don’t know why this is happening. I thought maybe belt slippage, but they are tight. When I start the job (without framing), the head moves to position smooth as glass, completes the job and returns to the home position perfectly. It almost seems like it is trying to move too quickly during the framing job and can’t keep up. I can’t find anywhere in Lightburn to slow down the feedrate during the framing function. Another thing I noticed, when I use the rubber band framing, the head movement is very rough. not smooth at all. Thoughts?

Home doesn’t invoke the homing code in a Ruida, it just sends the head to 0, 0, so this sounds normal.

The home switches are not limit switches. Once the Ruida boots it no longer considers input from the home switches. So it if misses steps or for some other reason is lost you have to home it again.

On mine, I can’t run it out of bounds, if it boots correctly.

If this occurs, it’s lost it’s position, so it needs to re-home.

I can reset my controller from the machines console and that causes it to perform a home operation. I don’t know what you do if you don’t have a machine console to perform a machine reset.

The only cause of steppers missing steps is usually the acceleration rate in the controller, it should not loose steps.

I believe Gweike machines have a modified firmware in the controller, so I can’t explain much of what a Gweike does.

My suggestion is to figure out why it’s loosing steps… If this continues you can’t do any work, so the number one fix should be getting the machine to work properly, which includes not loosing steps.

If this is a new machine, I’d contact Gweike.

![]()

Hello Jack and thank you for your response.

I didn’t realize that the Lightburn home button “does not invoke the homing code in Ruida”. I just came from 2 years of using GRBL with my diode laser and incorrectly “assumed” that it would/should behave the same way.

Thank you for the explanation on home switches vs limit switches.

No, I don’t have the Ruida display console (I’ve seen people add them though). Cost savings, I guess.

Rebooting the machine seems to be the only way to get it to re-home.

The camera does work, I just haven’t calibrated yet so, in the future there probably isn’t a need to “frame” the job especially since there is no red dot or laser output during framing anyway. Just force of habit.

Thanks again. Appreciated.

You mean power cycling the machine?

As far as I know, the Ruida has no way to initiate a home sequence from software, only from the machines console.

I don’t even know if the Gweike you have has the ability to add one. I know there are videos on Youtube about adding them to an OMTech Polar. The new Polar+ models have a console in them from what I’ve seen.

Have fun

![]()

Jack, Yes - power cycling the machine to force it to home.

I’m not sure if a console can be added to a Gweike either (custom firmware and all).

I watched a video somewhere that showed a person ordering a console and plugging it into his existing Ruida board then mounting the console in a 3D printed box which he sat on top of his laser enclosure. Probably was an OMTech.

Might read through this…

Have fun

![]()

Hi Steve, I had so many issues with my gweike crashing into the side and back, skipping teeth on the belts , after contacting gweike support several times they finally ga me a solution that works and had no trouble since I slowed the y machine max speed down to 150, if you still have trouble with skipping and crashing into the side / back this could also be your issue, ![]()

Jack, Good info. Thanks.

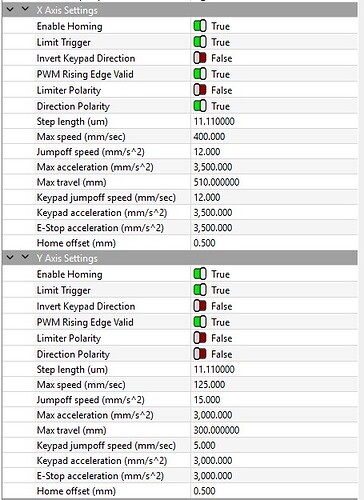

Keith, this may be the key. I’m pretty sure my Y-axis is factory set to 1000mm/s ![]() and my X-axis is set to about 400-450mm/s. I experimented with setting the Y-axis to equal the X but it still skipped (probably was still too fast). I will try backing both axes down to 150 and see what happens. If it works, I’ll start bumping up the speed to see what I can reliably get out of each axis individually.

and my X-axis is set to about 400-450mm/s. I experimented with setting the Y-axis to equal the X but it still skipped (probably was still too fast). I will try backing both axes down to 150 and see what happens. If it works, I’ll start bumping up the speed to see what I can reliably get out of each axis individually.

Keith, after reading some of your other posts on this subject, maybe I’ll just set both axes to 100mm/s for now.

Two things effect the machines performance.

Acceleration values for that axes and the mass of that axes. Acceleration values are limited by the motors torque or power to be able to get the axes to the set speed.

It’s conceivable that if the machine changes direction in the right directions, acceleration could be more than it can handle, resulting in a loss of location.

I assume you’re speaking about each axes speed being limited, not the acceleration values set within the Ruida. I’m also assuming that your tube is mounted on the Y carriage? This adds substantial mass to the Y axes, so it’s acceleration/speed values will be more limited or conservative.

Again, assume a speed limit, not an acceleration value. Realize that the tube/lps can only respond withing a certain period. All of these I’ve seen have a placard specification of 90% voltage within 1mS.

Taking 1mS (1/1000 of a second) as worst case, if running at 1000mm/s - the head is moving a mm each mS. You can only toggle the machines tube state every mS or mm.

| Speed mm/s | Best possible DPI |

|---|---|

| 1000 | 25.4 |

| 500 | 50.8 |

| 250 | 101.6 |

| 125 | 203.2 |

You can easily outrun the lps on most of these.

I still think if it’s setup properly you should not have these issues, so I think there is something in how the Ruida is configured that’s causing issues.

Have you posted the machine settings along with someone else with the same machine?

![]()

Yes, all of your assumptions are correct.

I left my X-axis speed set at 400 and set the Y-axis speed to 125 (was 1,000).

Now the movement is smooth as glass no matter where I fame a job.

Thanks for the speed vs DPI chart, I hadn’t thought about it like that. So much learning to do.

What are your acceleration values for each axes?

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.