Do you have a backup laser power supply to swap and test?

This video recommends swapping power supplies to confirm if the tube is failing.

Do you have a backup laser power supply to swap and test?

This video recommends swapping power supplies to confirm if the tube is failing.

I currently do not. Was considering buying a new L-PSU to replace as well. Just not sure what to get as of yet.

It’s much easier to check the output of the tube for proper TEM00 resonance or mode. If the tube is in question and it isn’t in TEM00 mode, it will never work or align properly along with poor operation.

If you have

They work.

Start with the tube…

If you don’t see an issue with it’s mode, then I’d move on…

One of the guys on another site has a K40 and claims to have run his for the pase 7 years…

![]()

Besides possible tube/LPS failure you should optimize your drawings.

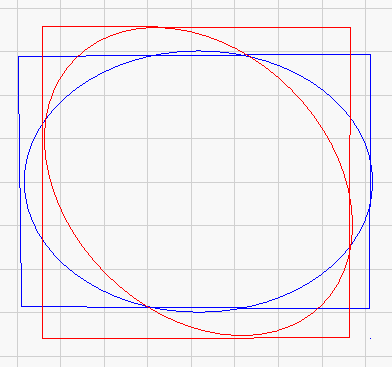

Something not right about the image you have. part of it looks off. I wonder if something got messed up. How did you view that?

So the original image I used was a bitmap that I then did a trace on.

The Ruida can store programs, right? Maybe it is getting near the storage limit. I think I read somewhere that they go off in La La Land when the memory is near full.

Worth a shot. Let me clear some of the old files out and see if theres any improvement.

Found out how to clear all jobs stored on the Ruida. Cleared some 90 jobs still loaded ont the controller then ran the job twice. In two different spots and came out darn near clean now. I dont know if that really was the issue or part of.

Making Progress!

Those light strips appear symmetrical in the pattern.

That pattern should not be sitting on top of something else, like a big filled circle.

That is just my opinion and I have no science to support it.

Agreed on points 1 and 2. I need to see if theres still some artifacting going on. The circle was a drawn in object and then grouped with the image to create a single object which I then did a flood fill job with. The light line does appear to be in the same spot as normal and only when I run the jobs using 0 degree scan angle so it’ll engrave bottom to top and left to right. when I ran the job on a 90degree scan they lines weren’t present.

To me that is a clue that it has something to do with the ratio between the X & Y in the laser dot. When traveling primarily in the Y direction, the dot is about 25% wider. Maybe increase the DPI 20 or so and see if it fills in using 0 degree.

where at would I do that?

If you think it might be to do with dot size/shape on a diode, I rotate my work 45 degrees in lightburn, this will give me an effective dot shape of a square regardless if XY ratio.

Ok, I spoke out of turn. I forgot you were on a CO2 machine. 90 good and 0 bad tells me you have a mirror alignment or dirt issue. @jkwilborn knows these machines verrrrry well, so I will ask him join in.

Yes, that will do it for the diode. You will get a lot more inertia motion on the Yaxis though. Too bad they can’t design the laser head that way.

By the way, I am getting better at Node editing!

Yes they could design it that way but it is really a cost decision by the manufacturers I would imagine. yes there are things like speeds that need to be taken into account, if you do you can get some great tab/slots on boxes and no glue required.

With the people I know, no glue is not an option. ![]()

In testing i made an acrylic box that I could drop from shoulder height with no movement of parts.

I think your problem is the wood itself, have you tried to do the same job but engraving at 45d