I tried reaching out to Ikier and got the predictably useless response … “here’s a link to the user manual”. Basically the same response I got when pressing for a firmware that addresses the extension kit. I’m tired of bouncing emails back and forth with people that don’t speak English (nor I, Chinese) and clearly aren’t technically informed. Took me a week of back-n-forth to get the most basic “change $131 to enable extension” sort of response. Thanks. I got that on my own. Machine still won’t use the full bed offline. Not that I care, but it still ain’t “right”.

ANYway,

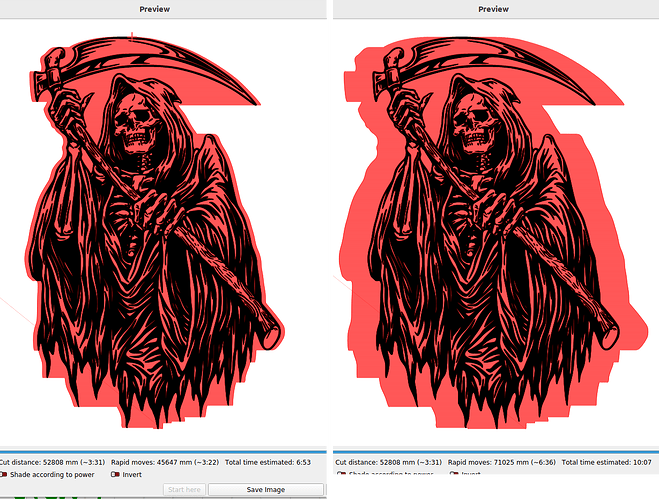

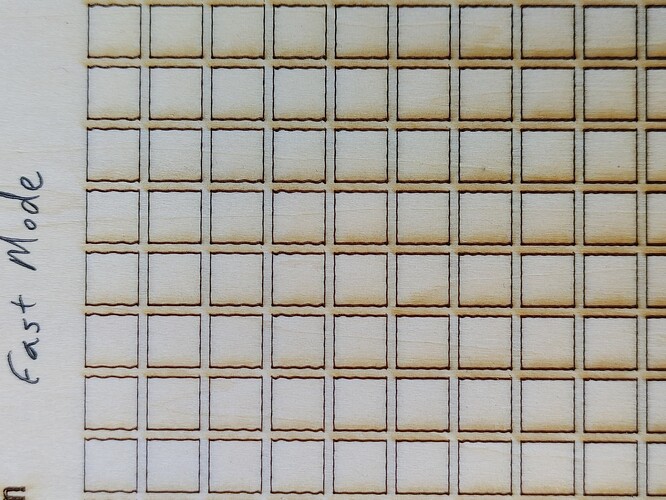

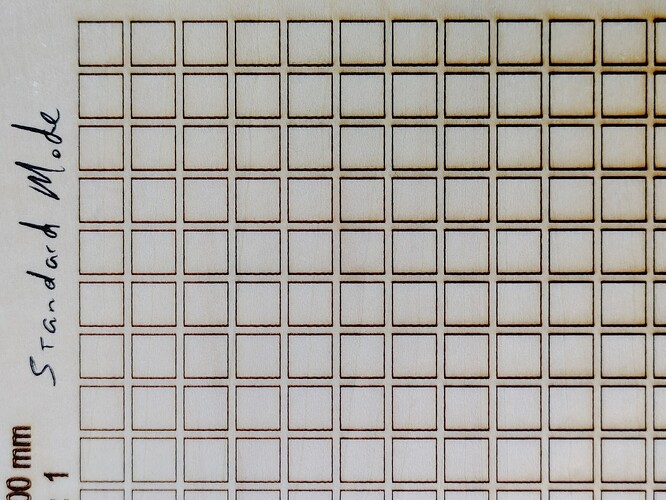

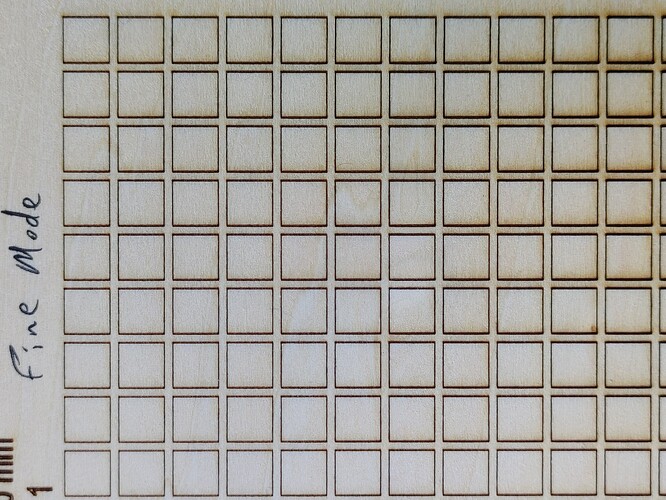

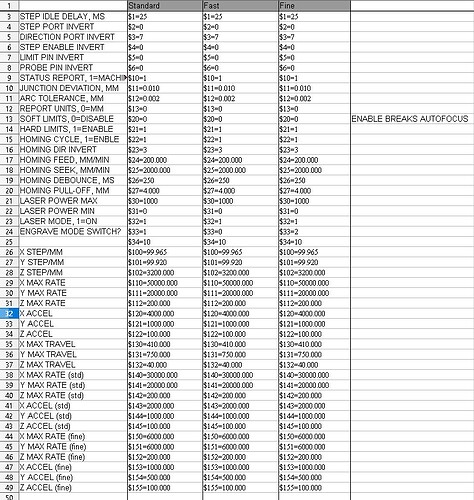

These machines have three “modes” available thru the offline/integrated touchscreen. “Fine”, “Standard”, and “Fast”

Per the manual, this is all that’s said (verbatim)…

“Fast - Highest speed, normal engraving accuracy”

“Standard - A precision-speed-balanced mode which can be used as a general mode (factory default mode)”

“Fine - best accuracy, slower speed”

OK. Sensible enough, but I want specifics.

If anybody out there knows, I’d like to know…

Does switching these modes somehow affect external machine control (Lightburn) or is it limited to offline/thumb drive control only?

It would seem to be altering machine parameters (interrogating and rewriting gcode prior to execution seems unlikely), but is it restricted to volatile settings or a table-switching feature in the firmware or what?

What exactly is is changing? Max speed and Accel seem obvious, but what about stepper motor parameters and other things?

Up to now I’ve only used “standard” mode.

I hope to investigate a bit this weekend by changing modes and comparing $$ reporting. Maybe try running the same file thru LB using the three different modes to see if I can tell a difference.

If anybody can shed any light on this, I’d appreciate it.

Also thoughts on an enlightening test procedure and/or files?