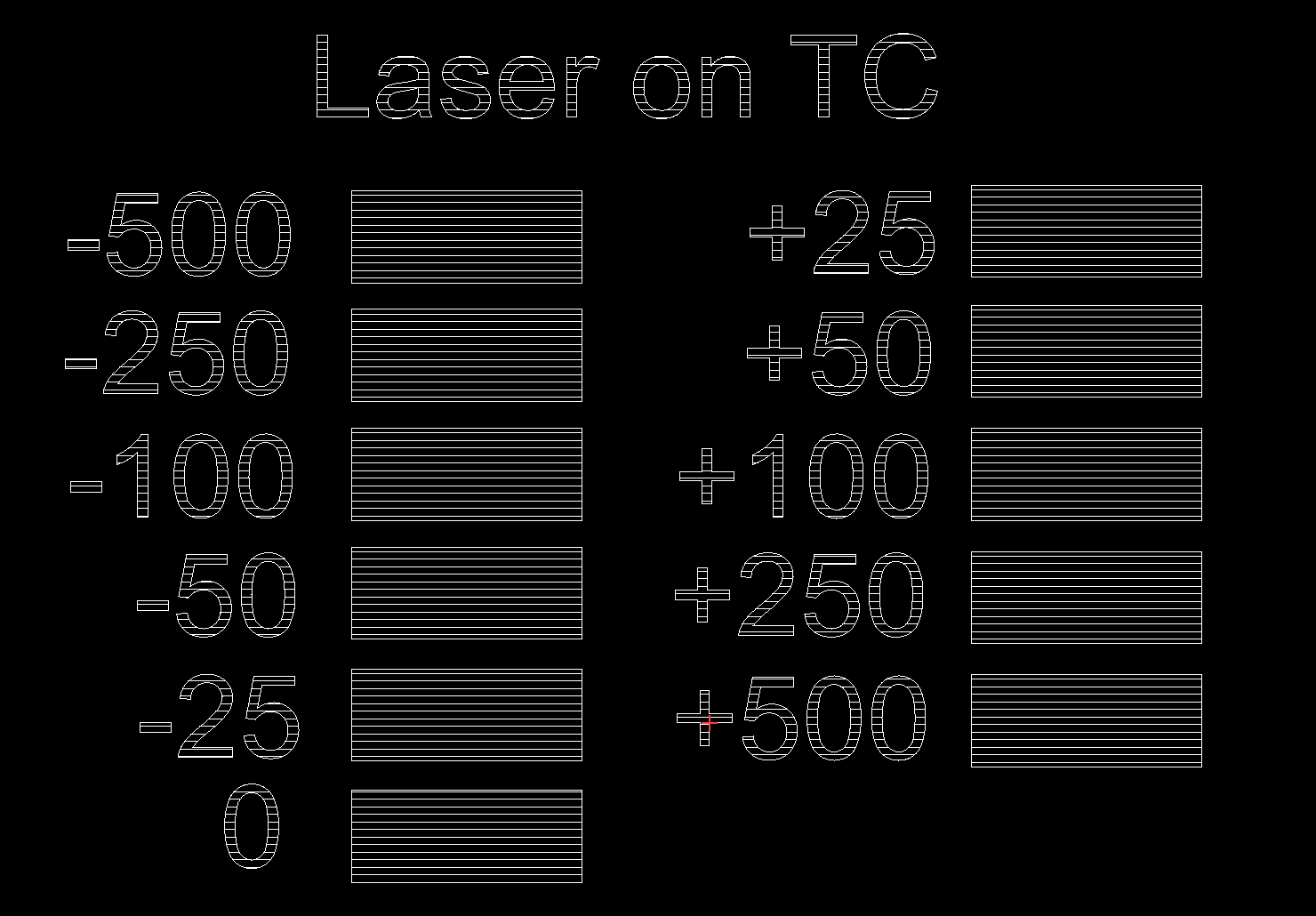

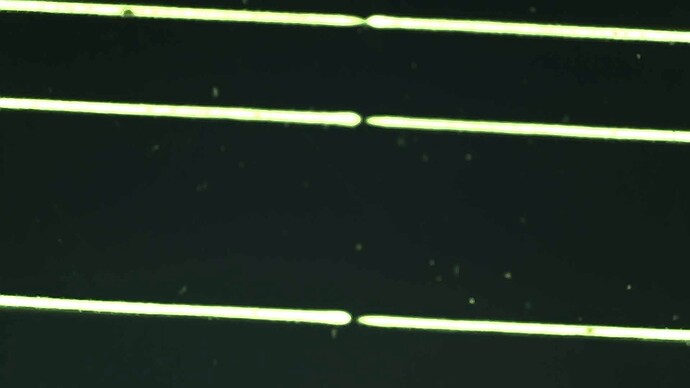

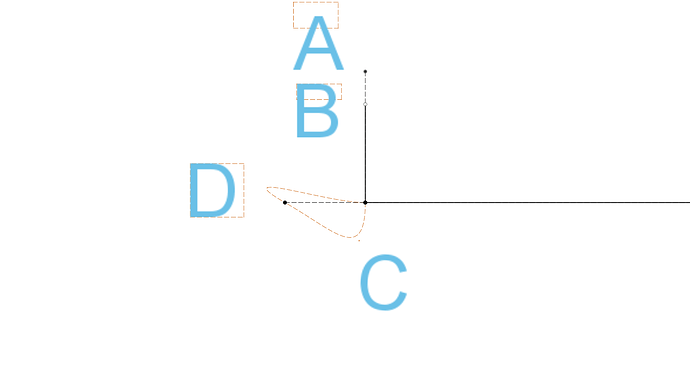

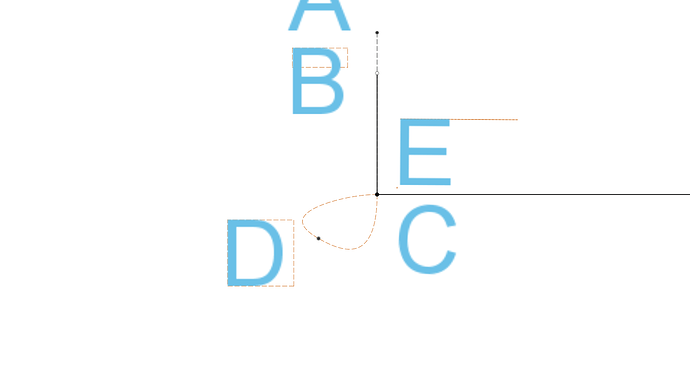

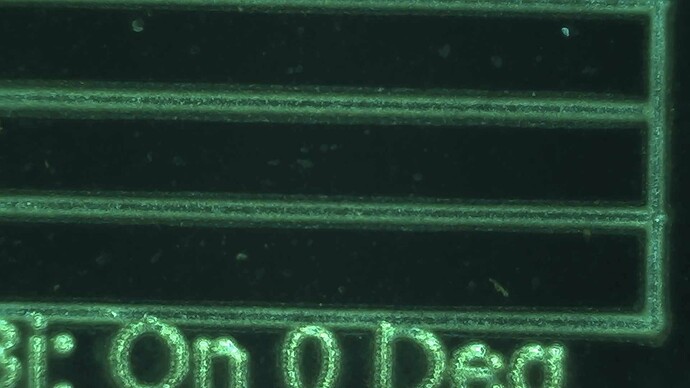

I noticed that the cut is basically flat bottom, except if I look close the edge is notably deeper. I’m running at 5000mm/s with 45 deg rotations and the timing is set very accurately. BJJCZ

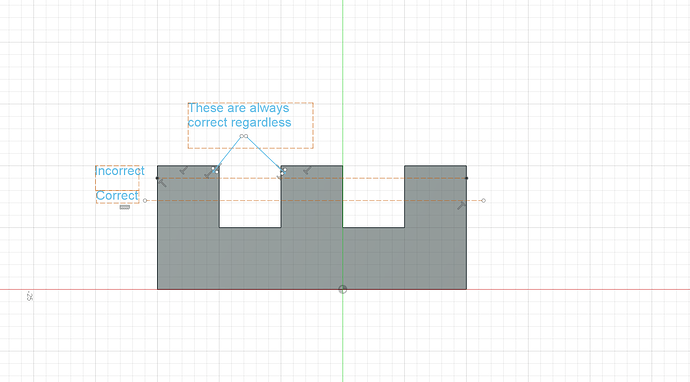

This is making me conclude that LB is commanding the galvo to the start point, and giving it the same pulse density given anywhere.

This is unlike CO2 lasers where the Ruida controller automatically calculates how far it will take to accelerate to the commanded speed, and will start the motion far enough outside the user’s cut to guarantee it is running at constant velocity at all times it is rastering. I know this is implemented in the Ruida and LB doesn’t actually control it. But BJJCZ doesn’t seem to have such a feature.

This appears to be jumping to the start point, telling it to fire at THAT point, with no “runway”, and maybe the same on the stopping edge?

Galvo are fast, but the acceleration is actually far from instantaneous.

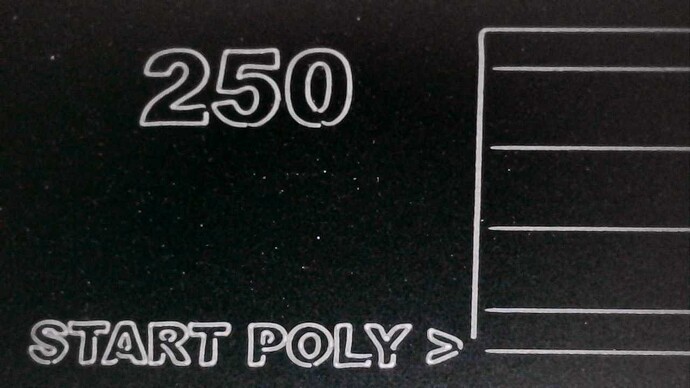

This is pretty bad news for my attempt at precision-depth fills. Show-stopper, actually.

No, we can’t just go slower. Well, you could, but at quite a cost. I’m working on carbon steel and I can see that, on my 300W, 80ns gives a smooth bottom and will not cause bluing from excessive temps. 0.0150 LI works with the 110x110 lens’s spot size. The best result seems to consistently come from making the freq of the spots spaced the same as the LI, so freq= speed/0.015

I have been going back and forth. Longer Q-pulse keeps meaning the scan has to be slowed down more and more, and freq scaled down to maintain the sq pattern, to avoid creating a HAZ (heat affected zone). Now,100ns can also cut without creating a HAZ, but the speed and freq must be lowered together below the HAZ point and then the net removal is actually slower.

Similarly, 60ns can scale up speed and freq higher than 80ns. But of course there’s still a limit of speed and freq before 60ns creates a HAZ. Testing shows that the removal rate possible without creating a HAZ is worse than 80ns.

So, 80ns is looking great. My JPT M7 300W datasheet says the cutoff freq of 1050KHz for 80ns. That’s where I’m using all the machine’s power.

I’ve been iterating to understand this “sweet spot”. It’s quite real. I can still get a very accurate scan at 5000mm/s, the freq is still speed/LI=333KHz. Until I can upgrade my SG7110 head with the SG7210, I probably can’t go much faster.

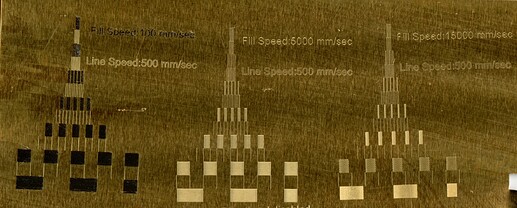

But, the faster I go, the deeper the cut is along the edges. If I slow down, the edge effect is ultimately less dramatic. That tracks, the distance needed to reach 300mm/s as opposed to 3000ms is much shorter and shallower- but it’s still there. But then we’re crippling the machine by limiting the freq output due to this prob. The machine needs to be able to use this speed.

The answer seems obvious: the BJJCZ isn’t inserting raster “extend space” like a Ruida. Can LB add some padding length at the start and stop of each raster line?

If not, galvos are going to be flawed at a pretty fundamental level.

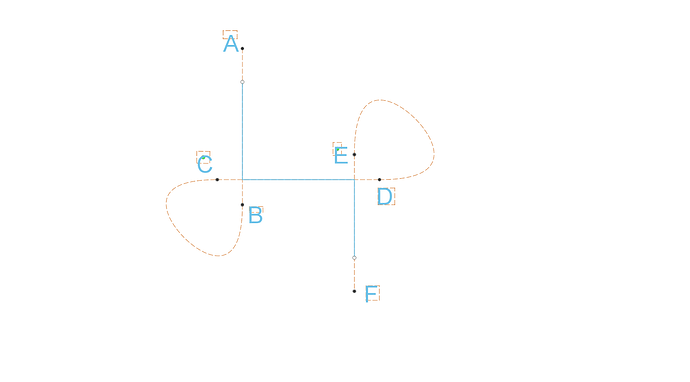

Or am I missing something fundamental and don’t have all my timing settings right? This is the TON/TOFF that makes a horizontal raster line doing GRAPHICS mode line up its features with a prior vector cut running vertically. So I think that’s correct