I recently bought a LaserPecker 5 - I own an LP4, which I love. The LP5 was advertised as Lightburn compatible, which is why I bought it. It is not. Nor rotary, for one. Also, you have virtually no control over the fiber laser - you can set the power and speed, and that’s about it. If you want to use the fiber laser, you are stuck with the LP Design space which isn’t that bad, but has some serious shortcomings controlling the fiber laser - and it is a quite good fiber laser. Y’all need to crack down on folks saying their systems are Lightburn compatible when they are not. I’ve been burned before buying a laser system that used their own proprietary software and I resolved to never buy another system that was not lightburn compatible, but I was deceived into doing it again.

I don’t think this has nothing to do with Lightburn.

The vendor is claiming compatibility, not Lightburn, as far as I know. You should speak to the manufacturer/vendor about it. Most of these places have roots in China, it’s not like Lightburn has much control over them.

xTool and others have produced lasers that mostly work with Lightburn, but they have special features that are not supported by Lightburn as there is no standard.

![]()

You have more control than you think. Lightburn needs to publish a list of laser systems that are fully compatible with Lightburn, followed by a list of laser systems that are only partly compatible with Lightburn, with functions Lightburn does not support.

Systems which are fully compatible with Lightburn should be recommended for use with Lightburn, those with minimal or no compatibility should not be recommended for use with Lightburn.

A cease and desist letter should be sent to folks who advertise Lightburn compatibility but are not. A list of minimum requirements for compatibility should be established - this can be pretty basic - like compatibility with ALL of Lightburn’s control functions. Advertising Lightburn compatibility but not rotary or depth map (unless you use their proprietary software) is NOT compatibility.

I just ordered an xTool S1 40W, advertised as Lightburn compatible (I wanted more power, and a closed system) - I’ve been using an open frame Atomstack 20W which I have been quite happy with. I haven’t gotten the xTool S1 yet, so I don’t know what functions are not supported by Lightburn - I will find out this week. If I knew in advance what functions were not supported by Lightburn, I may have chosen to upgrade to another system - I have a plethora of Lightburn files of things I make. If the xTool S1 cannot load and run these files, I’ll have to try and send it back and buy something else. I would have not bought a LP5 if I had known that the Lightburn compatibility was virtually non-existent.

I think I’m very realistic.

You want Lightburn to continuously search the Internet and find an occurrence of Lightburn compatibility.

When found, purchase a machine with all it’s options and test it to see if it operates everything correctly.

If it fails, engage an attorney to send letters to companies in China…

You issue is with Laser Pecker not Lightburn.

Any of these that are not standard gcode may not be supported with that option… xTool has a co2 that follow the shape of spoons and such, but isn’t operable from Lightburn. They claim it’s Lightburn compatible.

Hope they take it back from you.

Good luck

![]()

You’re right about this. It’s not at a point where I can talk about it, but I can say there is a plan and it’s moving forward.

Our Engineering Director @adammhaile has an LP5 on hand. The compatibility issue is currently being addressed.

LB 2.0 will have better support but not full. Their rotary works in a weird way and there’s not a ton we can do about that at this point. But controlling both lasers actually works and you can make macros for the various other features. I’ve sent them an lbdev (LightBurn Device Profile) file with what I was able to make work.

We’re actually in the process of doing exactly this. I can’t give much more detail than that at this point, but we have a compatibility list with ratings that you’ll be able to check.

I would be most happy if I could get LP5’s fiber laser to engrave height mapped files from Lightburn. That is my biggest issue.

At present, no GCode-based galvos support this, because they don’t register in LightBurn as galvo devices, just as GCode devices. (I assume you’re referring to the “3D Sliced” image mode, which is galvo only)

Bummer. But, being stupid, after quite some time, I realized a simple solution to my problem. The LP5 software moves the laser closer to the item being engraved with 3d bit sliced image with each slice. This is great for very deep engravings, but for metal, the smallest increment able to be selected is way to large, and the laser goes out of focus after several slices. The LP5 people would not admit that this is a problem and told me to “engrave a softer material”. The simple solution is to unplug the electronic lift mechanism after the initial focus - a bit of a pain, but at least you can engrave a 3d slice image on metal

For all practical purposes, the xTool S1 is Lightburn compatible. Not only does autofocus work with Lightburn, the focus can be manually set in Lightburn in the cut settings - something I may start doing to save time. While you cannot control the exhaust fan timeout from Lightburn, it turns out that the exhaust fan timeout is in non-volatile memory so it can be set with xTool software and it will remain even when the machine is turned OFF and remain set when run with Lightburn.

I use Xtool S1 with Lightburn exclusively and have tested with Lightburn 2.0 rc5. I show the capabiliteis on my youtube channel.

I Love Lightburn with my Xtool S1..

Brian

Fairly sure this will be a rhetorical question, but is there a way to get the framing laser with the LP5 to chill out? I learned the hard way that framing with the LP5 in Lightburn actually causes it to engrave on the material. I love Lightburn and absolutely HATE Laserpeckers LDS software, so the more I can use Lightburn, the happier I will be.

I don’t own a Laserpecker, so I can’t confirm this but:

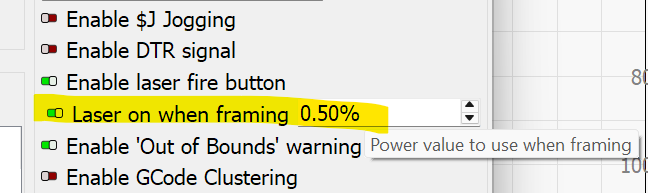

Did you enable “Laser on while framing” in the Device Settings?

You may need to lower the Power value here:

This is off by default with the current LaserPecker Device Profile from here but I believe, they didn’t update it for Adam’s file yet.

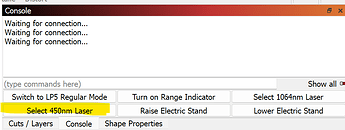

Update: You may need to first switch to the 450nm Laser with the macro from the Console window.

I double checked that “laser on while framing” was enabled and that I am using the 450nm laser. The lowest it will allow me to go is 0.40% which is still enough power to engrave the material. If I go lower than 0.40% nothing happens

I have a LaserPecker5, as well as a LP4 (and other lasers than actually run on Lightburn). I love my LP4 which works quite adequately well with their Design Space. LP5, not so much - i bought an LP5 because it was advertised as Lightburn compatible - it is not. Very limited control over the fiber laser, but LP5 (and LP4) are really not compatible with Lightburn, so much so that I’ve given up even bothering to try. I just suck it up, and use Design Space. Complex stuff I draw in a CAD or Lightburn and import into Design Space. I periodically get after the LP folks to improve the software a bit - even sending them examples of deficiencies - but I’m pretty much ignored. I suspect the LP folks are not in control of the software or firmware. Anyway, on the good side, the LP5 fiber laser is quite good, and puts out the 20W optical power, or maybe even a bit more, that is as advertised.

I agree, the LP5 is a pretty good laser. It’s the LDS software that is absolute garbage.

Which material are you using?

So, if you enter 0.2%, you don’t see anything?

Make sure to first run the “Select 450nm Laser” macro here:

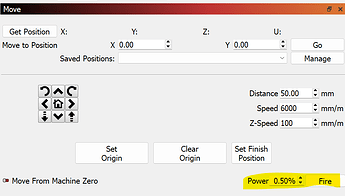

Then press the fire button here:

If it’s still marking your material, try a lower value in the “Power” field next to it.

So, I currently writing my bachelor thesis on a experimental setup, that uses the LP5 as a endeffector. I had to do some characterization and scince I use the grbl style communication interface I thought I might post my findings here as most of it applies to Lightburn users as well. (LP Firmware Version used: V8.0.2)

LaserPecker Design Space:

Lightburn and the horrible, horrible Laserpecker Design Space communicate to the machine in quite different ways: While both can be connected via serial com port, LPDS uses mostly a binary protocol, while Lightburn uses the text based grbl style protocol. I wasn’t able to reverse engineer anything meaningful from their protocol, so I wont go into details about what I tried but my findings are as follows: Files are send in full and then executed, resolution for shape position is 0.1mm (urgh) and at least parts of the toolpath calculation is done on the machine as the transferred data doesnt grow substantially, when the number of moves is drastically increased. I might be wrong on the latter, if there is a parallel communication channel I dont know about … reverse engineering binary protocols is way outiside my comfort zone and capability and I just stopped trying after some days. Surprising was, that LPDS itself uses gcode on some occasions. i.e. when doing deep engravings. That explains why some settings dont work on deep engraving like you would expect. Namely fiber frequency and resolution. Changing the frequency setting does nothing, and any resolution over 2k is as good as using multiple paths.

The grbl style protocol:

The grbl style protocol works mostly like one would expect. The buffer sizes you can request appear to be correct and you can use both streaming protocols documented on the grbl github. Lightburn appears to me like it uses character counting, but with waiting for the planner buffer to be empty before sending the next round of lines. I tested this one against the official implementation as well as one where you can specify a mininum buffer fill before sending the next round and did not find any performance difference exept that simple send response is slower as it should. The settings print out you can requst appears to be generally correct, but change requests are ignored.

Brightness: $30 and $31 describe max and min brightness values, that are set to 255 and 0 and appear to be interpreted a an integer, which explains why 0.4% is the lowest possible brightness setting in Lightburn (0.4% * 255 ≈ 1). This is also the only advantage the grbl style protocol has against the proprietary one as you can only set intensity in full percent steps using LPDS.

$100 to $132 give away the main disadvantages this protocol has against the proprietary one.

Resolution: Steps per mm ($100 to $102) is set to 25. That means one step every 40µm. Thats 2.5k not 8k in theire lines per dm resolution metric. Every position Lightburn sends is rounded to the closest position on a 40µm grid.I checked that with running the laser point over a pinhole sensor in 1µm increments and checking the change in measurement.

You can have higher resolution: I.e. when rotating the line direction by 45° so you can get about sqrt(40µm) ≈ 28µm line interval, but this will result in jagged start and end positions as those will be rounded to the 40 µm grid.

Speed: Speed ($110 to $112) is limited to 360,000 mm/min. Thats 6,000 mm/s not 10,000mm/s as possible in LPDS. You can check that yourself: increasing the speed over 6000 mm/s wont reduce the duration of any program, not matter how many long and straight lines it includes.

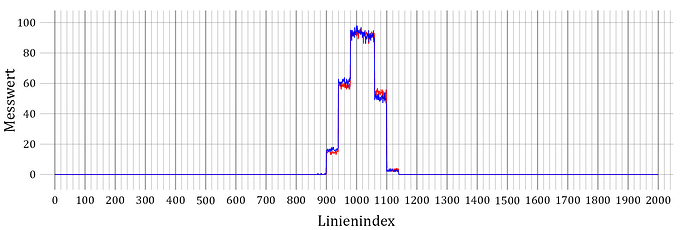

Accelleration: Accelleration ($120 to $122) is set to 750,000 mm/s². I cant compare that to LPDS as its nowhere stated. But it appears to be correct. Checked that by timing the length of different programs containing lots of straigt lines of the same length. Different programs with different line lengths result in different cutoff speeds from that on an increase in speed wont result in an decrease in time. (X-Axis: Speed set in Gcode, Y-Axis: Relative run duration; Lines are measured values, black diamonds are theoretical values).

Hysteresis/“Backlash”: Not quantified yet, but appears to be around 10µm - 40µm, but also varies depending on the position in the work area. Will follow up.

Precision: Not tested yet but I doubt the 0.0027µm claim. Will follow up.

Accuracy: Not tested yet. Will follow up.

Flatness of focus area and consitency of focus size: Not tested yet, might be followed up.

Concentricity of fiber and diode sources: Very bad. Depending on position in work area I get multiple mm of displacement from framing with diode and engraving with fiber.

Real time commands: The only real time command, that is actually executed immediatly is

0x18 (Soft Reset) if you need to turn off the laser source now programmatically, use this. Dont rely on ! (Feed Hold) or 0x84 (Safety Door). Whether this is an oversight by LaserPecker or theire interpretation of “decelerating to a safe stop” (as stated in the grbl documentation) is unclear to me. ? (Query Status Report) works somewhat, but the position doesnt appear to be accurate or up to date, but I dont think a DRO on a galvo is a reasonable thing to have anyways.Fiber frequency: Doesnt appear like the people at LaserPecker even care. There is not M command documented or used by LPDS. Cant be that hard as xtool has one.

HI Aaron, sorry for the delayed response. I have tried using anodized steel as well as aluminum with the same results. If I go below 0.4% the framing laser does not come on at all. At 0.4% it engraves the framing square lightly and at 0.5% it engraves the framing square significantly. I also confirmed on all of my tests that I was running the 450nm laser. I have not tried lowering the power field. I will run some tests playing with the power field to see if I get the same results.