Great,

You didn’t say which changes (if any) were made.

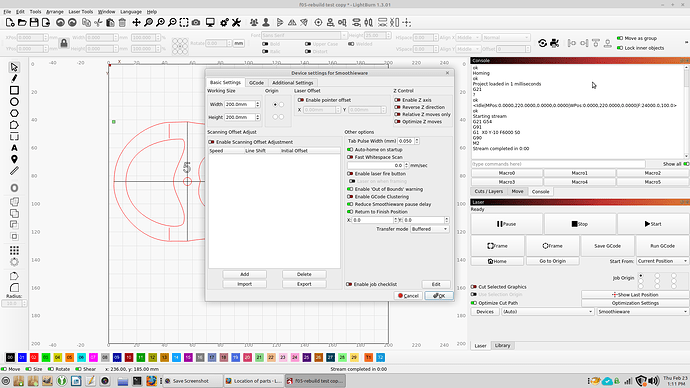

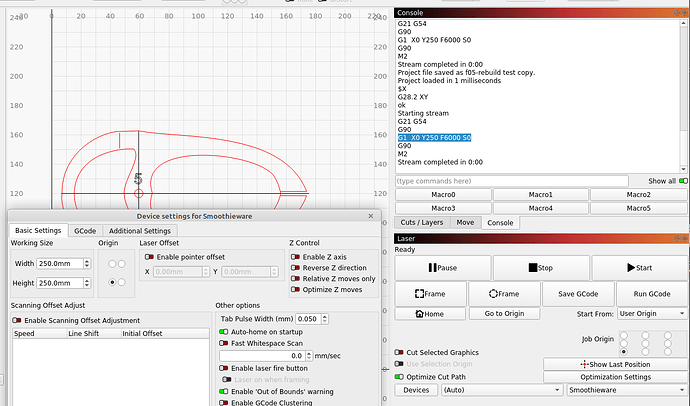

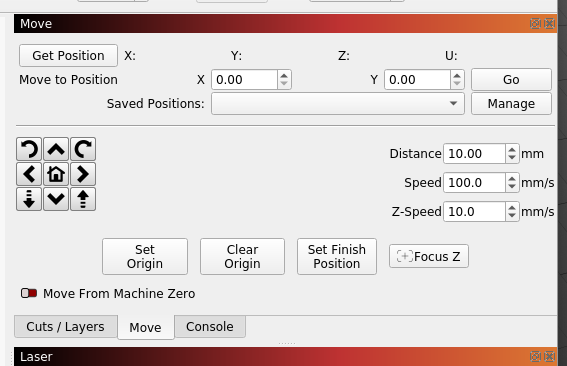

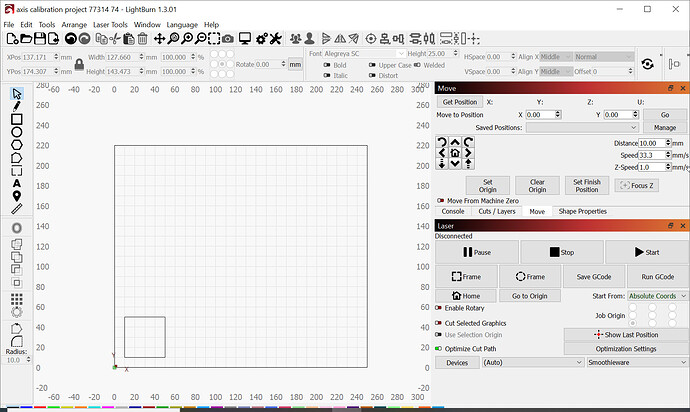

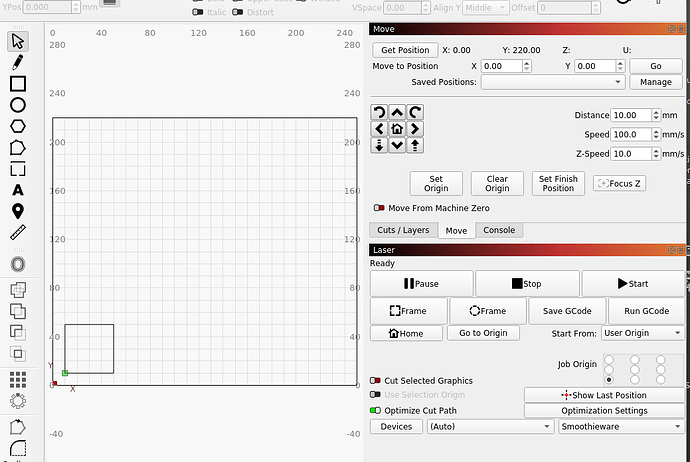

Please zoom out to show the LightBurn workspace with the Move window and the Laser window.

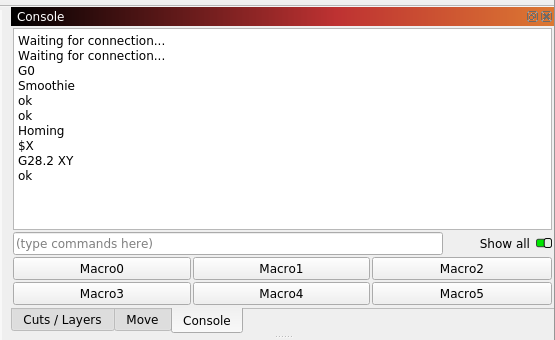

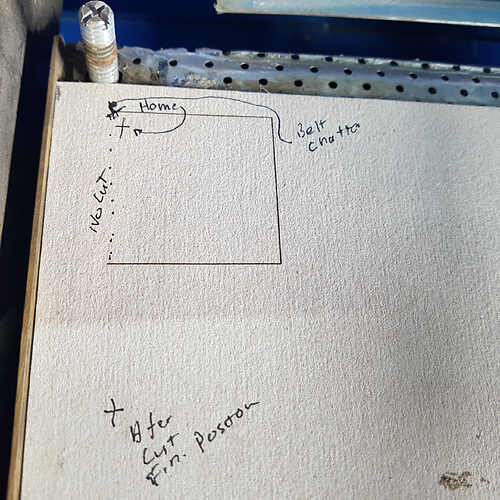

Great! That’s a welcome relief. It sounds like the Y-axis crash is remedied.

This is possible but should be confirmed.

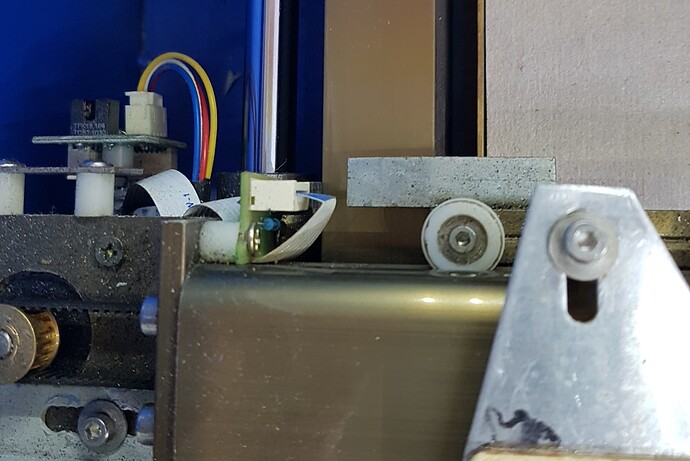

With the Power off…

Please measure the distance from where the Y maximum limit switch touches the gantry when homing and the same point where the gantry would be when the switch is depressed.

This number should be 220mm + the pullback as we’ve defined it.

The Laser will show us in the Move window where it understands that it is.

This should be what the engraver calls the Origin.

It should have arrived at what we’ve defined as the origin.

If it doesn’t arrive at the distance from the switch that we’ve defined then other Lost Motion has happened.

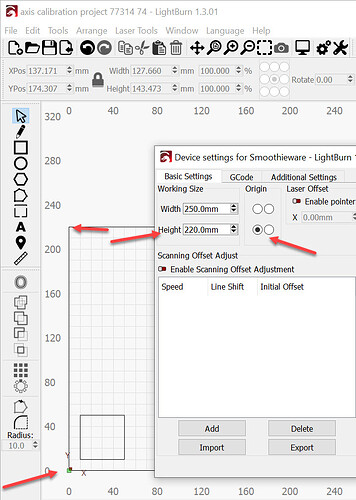

If the engrave head arrived at the Y=0 that we’ve specified and If the head has more available room to travel toward the front of the engraver, the Y-axis values can be increased in the workspace and in the Config file up to a point.

With the measurement in mind, after homing, you can pull the laser head forward and see how much motion remains in the mechanism.

If you find 10 or 20mm of travel available please don’t add the full amount back to the Y max. It’s wise to under report the maximums by a small amount.

The Y-axis values must be small enough to allow the switch to pull-off at Y max, and to never allow the hardware to ever touch the Y min (front) edge of the engraver chassis.

When contact (touch or collision) occurs, the laser controller continues to count steps when the steps aren’t moving the laser head. The position of the engrave head becomes unknown to the controller and worse, it doesn’t know that it doesn’t know. Because the engraver is holding the incorrect count, the engraver proceeds to put part of the engraving work in the wrong place after the collision. Holding the wrong count is called ‘Lost Motion’ and the collisions were certainly a contributing cause of the displaced lines.

Lost motion can also be caused by excessive acceleration, loose belts, loose drive sprockets and high speeds. None of these appear to be the issue here - but we’ll know with much more certainty after you measure the distance.

If the engrave head did not travel the beta_max_travel + switch pullback then we check the belts and sprockets and reduce speed and acceleration. Moving the engrave head along the Y-axis moves more mass (the head and the gantry) than moving the engrave head along the X-axis. The accelerations and speeds are usually similar in the defaults but what is possible is definitely different. The greater the mass the more time it takes to change direction with the same power given the same motor and the same motor driver.

Users can fine tune the X-axis acceleration and Y-axis acceleration by increasing them until Lost Motion occurs then reducing them back down enough to stop it. This is optional and can be done at your leisure.

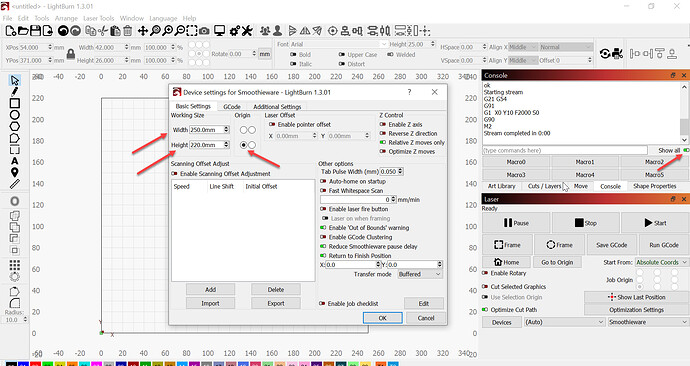

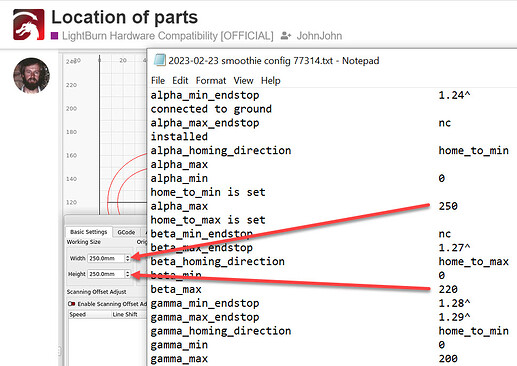

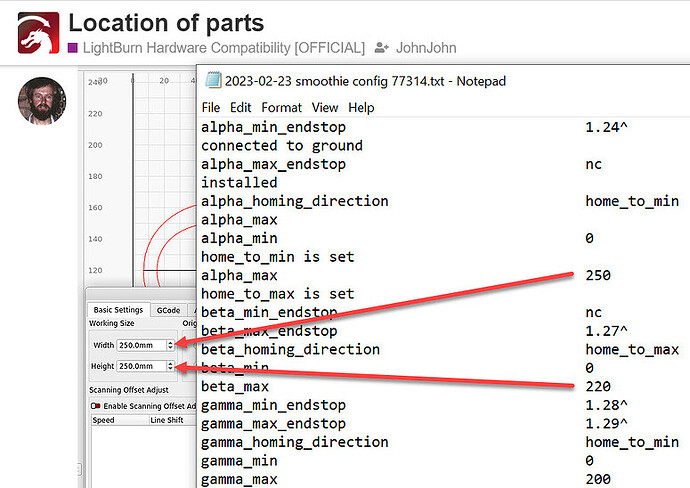

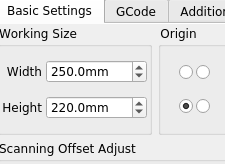

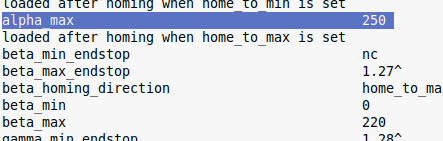

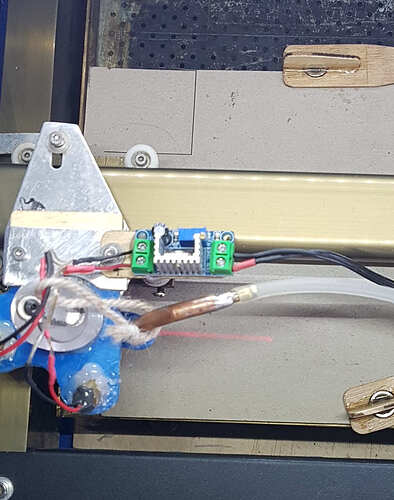

This picture is intriguing. The laser should be sitting at 0,0 - as we’ve defined it. The X axis position looks very close to the edge of the bed. I can’t see the X limit switch to confirm that it’s pulled off properly but it hasn’t seemed problematic.

Adding distance back into the X-axis (alpha_max_travel) is similar to the Y-axis (beta_max_travel) except that after homing and after the pullback is complete, (with the power off) you measure how far you can move the engrave head to the right before it collides. Be sure to under-report that number slightly as alpha_max_travel in the Config file and the LightBurn workspace (at your leisure).