Looks like there is wiggle room, big silver cylinder is just a button I never ever use.

I got it 38 days ago, it is also pretty new on the market. not sure which you meant

Hmm, that is an interesting theory, it could explain some things. How do I test something like that?

Do you think perhaps I should send these pictures to support as a possible manufacturing defect? I have a feeling they may not be as picky as you on the bonding looking suspicious, but worth a shot

This sounds like a different problem from the fast traversal problem. Might be worth exploring separately.

Yeah. Doesn’t mean a lot. I remember seeing the Mac firmware installation instructions online. Thinking those might provide some insight as well.

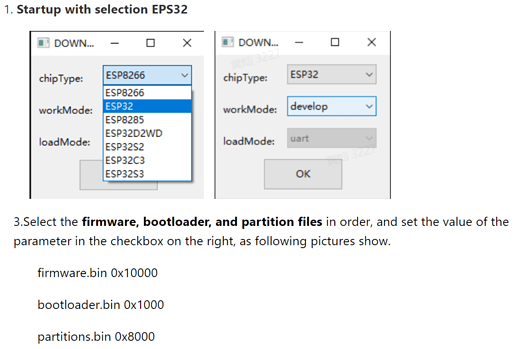

Just remembered to check the firmware update page and sure enough it has the information on the controller. It’s an ESP32. Probably similar or the same one used by the newer Orturs.

Given that Makeblock is using GRBL for this and GRBL is GPLed, you should be able to request source code for the firmware. Whether or not they comply is another matter. It’s likely based on one of the existing ESP32 builds for GRBL but would be nice to start working from where they left off.

It may be complicated because they may have some proprietary components mixed in there. Either way, might be interesting to disassemble the firmware file.

Worth a shot, I’ll ask them nicely and cross my fingers. Thanks.

I have not had time to tear into the firmware information yet, but it bears mentioning that I cannot reproduce this issue in “laserbox basic”.

The white space travel in “laserbox basic” does not appear to speed up as fast as it does in LightBurn. If i were to guess I would say it goes to 60-70mm/second for white space, where in lightburn it appears to try to make 100mm/second, and accelerates there quickly.

EDIT: I may have this figured out, more testing before i put my foot in my mouth

EDIT 2: I have nothing figured out, I thought the Move panel speed was affecting movement speed between shapes. I was wrong.

If I’m remembering correctly move panel speed does change transversal moves for Marlin firmware. But I could also be misremembering. Either way, there are times where it is indeed referenced.

Edit 2: All of this below is meaningless, with optimize cut path turned off the test square makes many more white space moves, and always gets a chance to lose alignment on a few of them no matter what I do. I’ll keep testing, but I didn’t want to raise false hope.

–Original Msg below–

When I had move speed at 45mm/sec it still messed up traversing between shapes when laser was running at 80mm/sec.

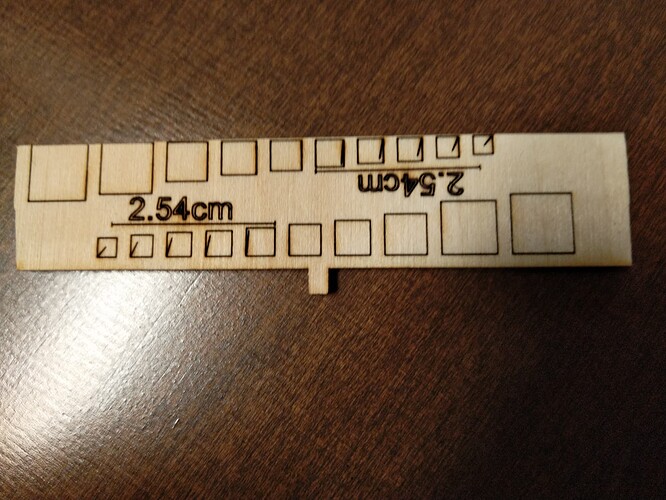

I was using the grid file, previously it was completely random when it would happen, but always when switching rows/layers, i need to run this test more.

I’m running tests on repeat with it exactly matched to the speed I am cutting at.

I have tested when “cut” and “move” are both 60mm/ sec as well as 80mm/sec. so far so good. To bad I use multiple speeds in my production files, but baby steps are something.

Hoping this helps me not ruin pieces until they fix firmware or I do something more drastic to the machine. My ortur pro2 should be here soon so I can take this D1 offline for some real work.

Edit: Continuing to run speed variations with the test grid from 10mm/sec to 100mm/sec (in 10 rows)

With move all the way to 20mm/sec it appears stable at all speeds, I will keep testing to see if I can nail down a recipe for myself and others to work around the locked firmware.

Probably just got lucky and it is waiting for me to post this and lose it’s mind again.

So far so good with new firmware, will keep updating thread. I downloaded new version of Laserbox Basic to upgrade firmware on xTool D1 on 1/22/2022

[Edit: It was “Overcut” setting causing issues. Not sure why it started now.]

It did not resolve the setting globally. The lead out appears to be being done by new firmware, not sure.

I do not see the lead out lines in the lightburn preview…

These shapes are all on the same layer.

The bottom row is with Lead Out turned off

The top row is with Lead Out turned on, but at 0 length

Even the larger squares are burning a lead out, but the angle almost follows the existing cut line. I hope it follows it perfectly on my larger shapes… testing testing

[edit: it was actually overcut setting causing the issue]

With lead in /out turned on, length 0.1mm, I now get the top row in below image. The bottom row is 0.3

I can work with that I think.

It is a minor annoyance compared to the alignment issues, but with more testing maybe you will want the info somewhere other than here.

In all my testing I have not lost alignment once, yet. ![]()

It isn’t over scanning now, even when turned on in layer… still working but…

the edges of my pictures are getting a heavy burn now of course, as it is slowing down in the field

Always something. I guess I need to dive deeper into alternatives, was hoping this update was going to be enough.

Power should be dynamically reduced during slowdowns to avoid burns. Are you configured for GRBL device (vs GRBL-M3)?

Also, make sure that “Constant Power” is not enabled in the cut layer or else power will not be variable.

I’m a little disturbed if the firmware is automatically introducing the lead in/out. That seems odd. I can’t imagine they’re trying to dynamically reinterpret the gcode. Is it possible that you’ve got some residual settings on those cut layers that you can’t see? Try restoring defaults to the layer and try it again.

It does appear to be dynamically reducing the power, but I am asking it to overscan.

[EDIT: My new laser did the same, I have deleted my prefs.ini, overscanning is working now on the new Ortur. I will report when I have time to test the xTool again to see if it was a config issue]

I will double check, but I have been opening the test file from save multiple times, so probably not a changed setting on all 10 layers it uses

I just hung this xTool D1 on the wall and I’m going to see what happens for other people while I learn my Ortur LM 2 Pro, wonder how much I am going to miss that combined laser.

That’s a shame but understandable. You know you could mount the D1 laser module on the Ortur right? if you were so inclined. If it doesn’t mount directly I can’t imagine it would be that hard to create an adapter plate.

Is the D1 a 12V or 24V system? If 12V you’d have to step down the voltage.

Definitely on the list of possibilities, thanks again! It wont hang there forever, but I need to keep working for now

I have been using the xTool D1 for a week with no issues using the new new firmware update.

[XTool D1:ver 40.30.002.01 B1]

I still cannot change machine settings

Will update if anything changes, but this issue appears to be solved

Oh wow. That’s fantastic. Sounds like they finally sorted it out. At least they’re taking feedback from customers.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.