Al ! – Having given it some thought I found a way to make your beast waterproof. Go buy a 4 to 6 man camping tent, set it up in the back yard

then tell the Mrs. & kids they have to sleep outside from now on. (caution -

you may be putting your own life at risk when informing the Mrs. So make sure you have good spot to hide in when informing her). There, nothing to it, you

just waterproofed your beast and enlarged your shop area by a several fold.

Last Nov. when we first started talking about these endoscopes, I bought two,

had to!! I plugged straight into usb with LB and it worked fine. best focal point was at 2" for me. Here’s my problem, with only a 12" monitor the image on my screen in LB was only about 1/2" sq. That’s a problem ! My win 10 has a camera program already in it, I never knew that until I plugged in my endoscope. I get a full screen image. So I just click back and forth from LB to camera. Works fine for me. This pic is my console with the 12 monitor. The move control window is only 3/4" sq.

And this one is where I’m going to mount my camera.

Those 4 T nuts came installed in my actuator.

So I’m going to get a piece of alum. channel 1/2" wide by 3/4" tall. I’ll drill two holes through the back side,(1/2" w) and mount to the actuator. I’ll drill one hole in each of the two 3/4" side walls to hold the scope. It should work fine,

I hope !

Already pulled that one off, that’s where the mustang hides from the weather.

LOL!! OK, time for a new plan.

thank you peter !!

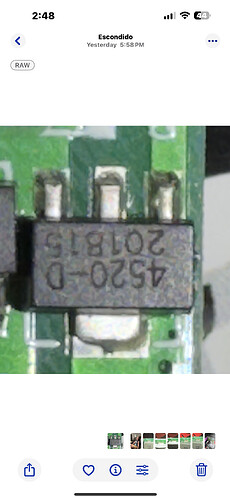

Hey Randy I was sending u a message cause I seen that u have a Zeus laser also. I have the Zeus x 7w and I fried a part was wondering if u might be able to help me identify what the part is so I could order a new one thank u

Hello Bryon: What you are looking at, (in your pic) is a “mosfet n-channel” power switching transistor. Used for PWM applications, power management and load switching. I don’t see anything wrong with your transistor. No burn signs, no cracks, little chunks or holes blow out of it. Most of the time you can spot the bad components and sometimes you can’t. A diode laser does not put out a solid beam like a flashlight. That diode turns off and on thousands of times per second. The hotter you run the power the longer the diode stays on per flash. So you might have a timing ic-chip or something else gone bad.

Power is not temperature but rather a measurement of time. So just going by what I see in your pic tells me something else “may” be wrong. And yes I have had many power transistors gone bad with no external signs of damage.

https://www.mouser.com/?srsltid=AfmBOor8R8TDMiY1LFWNhL_oFldkKPViWfW60bm84IOIm

https://www.jameco.com/?srsltid=AfmBOooyd1vtlU3Trw4no_E0gQ-9Z3GdeBBU4Ze43bFchugKKh_QQTxv

These are the 4 that I order from the most. I don’t really trust all the sales/auction websites out there! To many china made knockoffs that are bad news.

Let me know the outcome of your repair project.

Hi randy

This comment just got me thinking in a new way.

“Power is not temperature but rather a measurement of time.”

Do you know what I could read up on to get a better idea of the Speed/Power-(Time)/Settings relationship for diode machines.

hello Peter: One of my posts here in LB or maybe LA Hobby guy forum I tried to post a link only I could not get it to post. So I told everyone where to go to watch a vid that explains all that stuff in simple terms. I’m looking for the post now. Will let you know ASAP.

Randy

Peter: My post is here in LB. Scroll back to last Dec. around the 2nd or 3th.

I posted the vid on lasers. The vid is called Drone Killers. It’s a U-tube vid.

Three post back I said power is time. When a laser fires, it fires at 100% full power every time it fires. Using “pretend figures” lets say it takes 1 full second to reach full power in your diode when it fires that one flash, if you have your power setting on 100%. Now you set your power to 20%. That means that your diode is only going to fire for 20% of that one second in time. If your full power firing shoots a beam that is 1000 degrees in temperature, then your laser beam when using 20% power is only reaching 200 degrees temp. and so on.

Now forget time !! You are working with power and speed. The more power you run the faster you have to travel. I say power equals speed or speed equals power either way. Now you are cutting/engraving on hard wood like black oak and you are running at 60% power and speed is xx mm/m or even mm/s. You finish your burn, (as I call it), it looks great!! Now you swap out that black oak for something soft like balsa wood and you forgot to change your speed and power. Now you just ruined your piece of soft wood, chopped it up real good and maybe even set it on fire. LOL, I did that a time or two.

I hope this helps. Now I want to make one thing clear, yes I am an electrical engineer retired for 20 years now, but I don’t know computer “IT” stuff and I know almost nothing about lasers. I bought my first $200 laser about 3-1/2 years ago when I joined LB. Everything I know I learned here in LB and watching utube vids. You are going to end up making a lot of test charts for burning different stuff. I have a bunch of charts for burning tile, wood and canvas and several others.

Hope this info helps.

There a lot of people in that can help you better than me. jkwilborn, Nick,

and several others. Jack, (jkwilborn) is the one who taught me about power being a measurement of time.

Call out if there is anything else I can help you with.

Randy

Randy, Thank’s for passing on the learnings.

I’ll track down the Videos and learn what I can from them, but I think doing it will bring the real knowing.

I developed a rough Idea last sunday morning to burn a color chart per given material, about an inch x width of cutting deck. Divide the width into ten segments (invisible border) and burn from left to right at a rising power for each segment & speed for each new row of burns.

I’m not trying to reinvent the burn chart but when you build something from the ground up, you have this much deeper knowing of it.

Also looking forward to defocused burn experiments.

As it is, I’m learning the personality of Polycarbonate sheeting for enclosure lid and its ability to Not conform! LoL

Thanks again

Pete

If you plan on cutting that sheeting material with your laser, you better make sure that stuff doesn’t off give any bad gases. If you don’t know, go into “community laser talk”, make a post and ask.

Randy

I just did a search for “laser test files”. then I clicked on images and found a ton of test burn files/charts. Go look at those, get an idea of what you want.

You can also go to Esty and buy a lot of those files for charts.

Although it is an important issue to avoid toxic gases, the problem here is more that PC cannot be cut with a CO2 laser or can only be cut very poorly. There are various posts on the subject here in the forum.

Thanks for the heads up randy but I won’t be cutting any plastics with laser. I’m using a reciprocating trimmer tool for the cuts, heat gun for the bending “which is tricky” and two stage drilling of holes and mini sander for cleaning the edges of cuts.

After cleaning take a little torch and lightly go around the edges. That should give a give it a new smooth shinny look. That is what I do on some of my led lit signs. Some times I use fine sandpaper on the edges and that gives the sign a type of glow.

Thanks a lot I really appreciate ur help.

I’m just seeing your message now and I ordered a part from nexperia

Thank’s for the edge finishing idea’s randy. No luck finding the diode video…but I’ll find it.

I literally only turned it on for maybe 3 seconds max and after seeing that it wasn’t turning on I opened it up to take out the batteries and smelt something burnt… I know that’s probably all it would take to burn something out. lol but also I noticed that there was a lot of play in the battery compartment enough to be able to shake it and hear them jiggling around. Is there any possibility that could have shorted or burned something out by any chance?also when I opened it up to check the pcb I noticed that the black wire next to the mosfet that burned out came undone so I had to solder it back together. I’m not sure if when I unscrewed it tho if that might have made the wire come loose or if that could be the issue and if so do u know what else that issue could have damaged in the process of it frying that mosfet? Again I really appreciate u taking the time to help me out with this man