I believe have same machine. I’m 181 cm tall and made table 52 cm from ground. Its fit perfectly for me. Even I was able to install cooler underneath.

Aha! I’m familiar with the concept but didn’t see them from that perspective of the pic. Very good!

Thanks for sharing, it also looks very clean and practical. I also have a CW5000, so of course it must be under the laser machine

If you have time, at some point, I would be very happy if you would share a little of your experience with this laser machine. Was there anything you needed to repair or change? Do you want to install an extra ammeter or are you happy with the built-in? And, can the power supply be limited to suit the individually determined max output to fit the 100% scale in LightBurn?

I have it just for more the mount. I had a problem but not with electronic , mostly problem with adjusting lens and bed. It is cheap machine and sometime need tinkering. I had to change one mirror as was damage. Rest is calibration. Of cores, i will share my experience. If it is 60W laser should not go over more then 19 mW power . I conserve mine under 75% power what is cca 17 mW on mine laser.

… then we almost travel together

I’m well aware that price and performance / quality are closely related, but I’ve got a small cnc machine, a diode laser and a K40 to work quite well, so I hope that I also succeed with this challenge.

… and of course with the help of this fine forum here !!

I hooked mine to spare chimney so i don’t have problem with fan. The stock fan and air compressors are good for me at the moment.

would you please make a picture for me, of that label from the laser tube, thank you

77cm from the ground. Made out of 2" square stock, probably able to park my jeep on it. But I wanted the chiller to sit under it and it to be mobile. It ended up higher than I wanted because of putting the chiller under it.

I’ve worked on it so much, that I’m glad I made it a little too high. Can sit in a chair and work on the electronics…

Jack, do you have an original Ruida or a clone in your machine?

It’s a Ruida 6442G, stock…

Most of the electronics are stock, have modified the inside mechanical (some of the ‘Russ Sadler’ fixes) such as the lightweight head.

Have a motor driver and parts to move the rotary to the U axes, but haven’t got it done yet. Currently working on a High Voltage meter to be next to the ma meter.

The air assist (low pressure) and the extractor fan run off a SS switch driven by the ‘Status’ control of the Ruida.

OMTech guaranteed a delivery date when I ordered mine. A couple weeks before delievery they advised me it was stuck it customs. It was only 2 weeks late. Suspect it was sitting off Long Beach… I asked about the guaranteed delivery and they advised me that I can cancel it…

I have never been able to log onto OMTech site with any of my Linux boxes, even with Opera, Firefox or Chrome on them. I’ve spoke to them about it a number of times. The last one advised they only supported windows. Figured if that was the kind of support they had, there was no point in wasting my time.

ohh, I’m so looking forward to getting started with the machine. An ammeter comes on Monday, along with a small compressor and Russ’s nozzle is on Santa’s wish list.

… I have been in touch twice with OMT but through Amazon’s order site, they responded quickly and kindly but I hope I do not need their service.

They were nice, with the exception of the person that advised they only support windows machines on the web I had no problems with them. My 50 watt machine (45 measured) actually has a 60 watt supply in it, so I can’t really complain.

Which nozzle did you get?

I’ve found the compound lens my favorite for engraving… get the best dot.

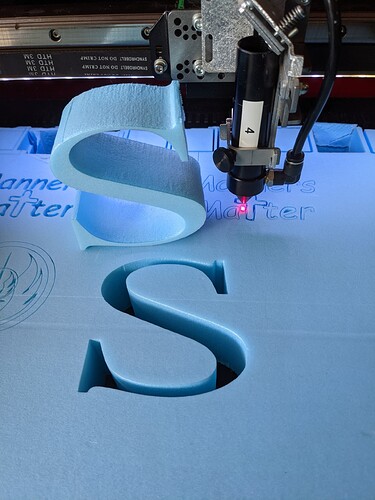

By the way, nozzles …, which lens should I use for thick foam?

I use the 4" if possible. It has a wide kerf since I’m depending on the generally wider unfocused beam to get through the material. Widest, it has a kerf of a couple mm at least.

honestly, I do not know. In the pictures, the machine looks differently configured as in the video on the same advertising sales page …

Did you get more ‘area’ after the head upgrade? Mine allowed me to add 44 mm to the Y direction.

Pushed mine up to 1650mm/s, great fun…

That’ll be the next upgrade once I get back.

While I wait for my machine, I prepare my workshop for this expansion. Today I made a slide valve for the Ø110mm that I use for my upgraded extraction. It’s a prototype with the materials I have for above, but it actually works very well. The ring segments could be replaced with whole rings but it eats so much material.

I’m supposed to glue the valves to the PVC pipe.

It’s great fun, but of little real value.

Anything you can do the remove mass from the head assembly will allow a greater acceleration value and will cut down on the slow down, turn around and speed back up trip.

The only thing on mine that’s drug back and forth is the air tube. I lost the whole drag chain and all of it’s brackets, mounts and other hardware. I think the weight went from about 1.4kg down to about 500 grams. Don’t remember exactly.