Try 115,200bps. I think I can remember that some had to do it a few times to make it work.

thanks,i will try

where did you get that NEJE software update tool forbreflashing?any instruction please,i have the same problem

same Problem, Neje Master 2S Max stopped afther an Houer or more. Updated with Neje_v.56exe . same Problem. Switched different length of USB Kabel. Reduced Power or Speed. It runs longer or shorter but same Problem. E-Mail to Neje no response. Negativ Statement on Shop Site was deleted. So there my Question here. How could i manage to Print from a Broken Point with Lightburn. I downt now how i could start at any Point of an G-Code with Lightburn. In other G-Code Sender is an point like Start G-Code from Number xx. And if i run on 115200 there in the G-Code Console Monitor this lines f x^??fx .Is this an error code ? The Problem it self, the Print Stops, i could only Stop the Job, afther this the Laser runs normal wit no issues, without reset or Power OFF On. I think there is an Problem with the data transfere from USB. I will Order a new Board from Neje. My SN is from Feb. and i think 1 of 100 like in the Post. Sofar How could i start a Broken Job with Lightburn.

First, you can’t start a broken job, you have to restart from the beginning.

Try to update the firmware a few times, I solved the stopping problem with that.

But after I had the problem with the stepping motors.

Don’t expect anything from the neje service. I had to send them a lot of videos, and I already knew that problem was the motherboard. So maybe you have the same problem. After no response, I wrote 2-3 more emails until I got the answer that my motherboard was broken. But since I got it from Amazon, they are not willing to send me a new motherboard. So I have to send back the complete laser to Amazon to get my money back, and then I should order a new laser. If I don’t want to do that, I have to by myself a new motherboard from their site.

hey Arun.

first ist this Step Problem only on x axis?

could you check the Temp of the Steppermotor Driver ? put your finger on it, it must be warm max 50°C not hot. or fist tip your finger at the Steppermotor, same not hot.

could you messure the current at 4000mm/ min ? its 0.7 amp Laser off.at 12 V

Make an big rektangle as big as your PNG pic in your vids, Laser Power down 20%, full speed 4000mm /min , check X Achxis Motor Temp. it should be less than 50°C

Maybe one of the ball bearing is defekt and the Steppermotor need to much current, and then the stepperdriver stops for milisecconds.

so cool down the driver with an heat sink.

Loosen the x belt an move fast the sled with your hand , bevor this unplug the steppermotor cable.

The steppermotor moved by hand could damage your Stepperdriver, he works as Generator.

If you move the sled with Hand, you shouldnt notice any jerks.

The new firmware http://www.neje.club/download/20210601/neje_grbl_uploader_v3.7.exe dosent fix my problem. at 115200bps.

but i have no Stepper looses, i am laser on mirrors and for one large pic ,all PNG, over 8 hours, i needed 5 attemts to finish. Always from Start, there was no offset. But i needet 24 hours. So the 5th attemt was the whole 8 hour job.

Just ordered and received new board. Installed and Same test burn is going now. I’ll report back soon on status

New board, first run: Ran 100% without any issues.

one in a row is a good start.

The problem is on both axis.

The problem can start also immediately, so the temperature shouldn’t be a problem.

I have sent a lot of videos to Neje, and they said that this is a mainboard/motherboard problem.

Morning.

My Neje 40W DoubleDiode draws 0.7A when moving home with 3 axes, only x in motion also 0.7A and stop motors also energized 0.7A.

The Laser Diodes draw 3.2A at 100% with a Fan. The Power supply delivers 4 A. That is a tight thin.

Yes , with 3 motors only drive 0.7A at the same Time, the rest goes to the laser. Thats just 0.2A / motor. My first Problem, the Neje Logo was on the x axis, and on the x axes home trip, the engine stuck on the logo. not enough power to move to the switch.

from neje Forum : Hello, the official current setting is 0.9A. There is a layout chip on the back of the motherboard for heat dissipation, and the temperature is controlled at about 55°; 42mm 34mm thick stepper motor is used.

Well at least NEJE responds to their forums

Any news?

My neje master 2s max has the same problem.

Did we miss your specific question? Please try again.

Same problem should use same resolution. ![]()

If you are having a different issue, we are here to assist, but please make a new post. We want to avoid missing it. Tagging on the end of something, saying “…same problem” does not explain the details of your particular issue. It helps us all help you get sorted and going as expected. Thank you.

Hi.

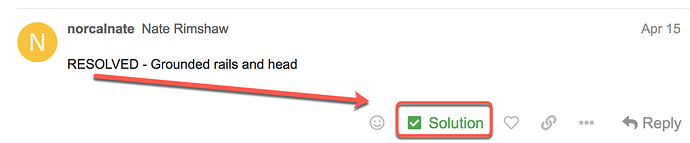

That is not the solution, it is wrongly marked.

The next day the author wrote:

[Apr 16]: I spoke too soon. same issue is back!"

U can start from preview window, move cursor till surtain spot and then start print from here

Can also be the neje firmware, they have a firmware stating that solution for that probelm

Hi, I know this post is old, but I started to run into the same issues these last days, and it got worse and worse. Ended up I couldn’t even cut a circle 20mm diameter without stopping in the middle. Strangely, straight lines (rectangles or right angles shapes) were working far better (but big shapes wouldn’t end correctly).

I tried all tips (firmware etc.) on this post to no avail. Then someone spoke about the power supply, and I just thought “straight lines keep the laser on the whole line, but diagonals or circles make the laser ‘flash’ spot by spot. During raster engraving, same ‘flash’ work while the head is running.”

So I decided to unplug the laser head and start the engraving process and saw it went smoothly until the end. The power supply stood cold. I remembered on “right angle shapes”, each time the machine stops was on a direction change, where the laser may be turned off then on again. The power drain of the laser seems high (fan is slowing down when the laser turns on at high power, I have the 40W head).

I had a 12V 12.5A power supply laying around for a future project, so I decided to wire that to the machine (keep attention to polarity, positive in the middle of the plug), and started testing, I managed to engrave a whole sign, half an hour job, without issues.

The faulty OEM power supply made the machine stop after a minute or two, sometimes after just a few seconds. But when the issue started, it happened after more than an hour. Things got worse day after day.

So for people reading this post and having this issue, just test another power supply !

My hint : use a 12V at least 4A power supply. Original is 2.5A and I would say it is less harmfull for the hardware to oversize it a bit.

Hope this helps!