The company I work for just bought some cheap Chinese lasers I was wondering if there was a lens assembly that is recommended that will help with the dust on the lens. And what kind of Grease do you recommend to use on the bearing rails?

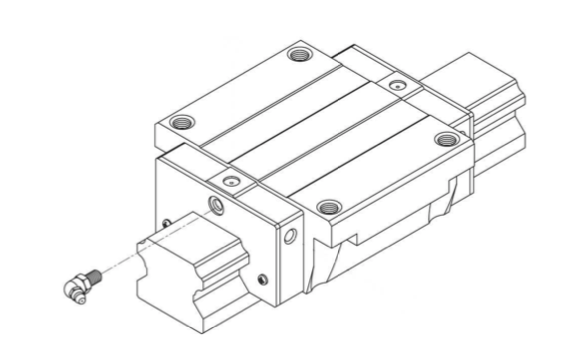

Any good light machine oil for the bearing blocks. If you ever pull the head, the decent ones have a plug to put oil directly in the bearing block. Otherwise, a little oil on a soft cloth, wipe on wipe off.

Excessive dust on the top of the lens is a sign of bad / wrong air flow through the cutting cabinet. You can’t eliminate it, but good air flow across the work for engraving, and over and down through the cut when cutting is the objective. If it comes in the front and out the side you have swirling air flow and that puts bits and pieces all over the place.

That’s what I’ve been using on our Universal laser machines. But did not know if there was anything better. Each machine has its own blower that vents to the outside maybe don’t have enough CFM or something is blocking it. The machines run 2 shifts for 8 hours a shift and The operators don’t like to clean them. Already had a lens crack in half on the Chinese machines. The Universal machines don’t get as dirty engraving.

just a note for owners of new machines.

they get shipped with grease on the rails.

this grease is only to protect the rails during shipping. the grease must be removed before use, and the rails oiled with light oil , like 3-in-1 oil.

Bell Laser sells a decent replacement tube.

I can cut MDF all week and just need a wipe, but acrylic, leather, glass, gets the outside of the tube filthy in no time.

As long as you have decent air-assist, nothing should get into the tube to the lens.

Watch the smoke from the cutting. Straight across and you’re good. Anything else and you need to start checking.

It depends what the ‘grease’ is. White lithium is what we use to lubricate and clean, it’s perfectly fine to leave it.

3 in 1 attracts dirt and can harden to a varnish - my hobby is restoring 1930-50s Swiss sewing machines.

that’s very helpful info Bo, thank you.

i wipe down our rails and re-oil at least twice a week, sometimes once a day if deep engraving traffolyte.

but you are right , that oil can harden after some time.

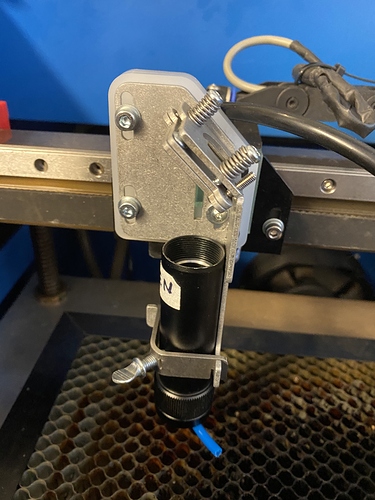

I have/had that same head assembly and my mirror/lens were rarely dirty as long as I had good air assist and a good exhaust blower. When I say “good” I don’t mean the ones the machine came with. I use this blower:

iPower 6 Inch 442 CFM Inline Duct Ventilation Fan HVAC Exhaust Blower for Grow Tent, Grounded Power Cord https://www.amazon.com/dp/B009LCEUEK/ref=cm_sw_r_cp_api_i_z6teFbM9KB2N9

And I use this California Air Tools compressor for air assist.

Quiet Flow 4.7 Gal. 1.0 HP Portable Electric Oil-Free Air Compressor

https://www.homedepot.com/p/305524481

I have a two solenoids connected on the output side of my compressor. One runs with the “status” pin on the controller is energized and lets a little air trough to keep smoke out of the head and the other solenoid is connected to the “wind” pin of the controller and is activated when the cut layer has air assist selected letting as much air through as I have my regulator set to (usually about 15 psi). Doing this my compressor doesn’t run constantly, which it isn’t rated for. Having said all of that I recently modded my machine to use Russ Sadler’s lightweight head design, but my air and blower has not changed. The other thing I did was put little stick on rubber bumpons under the lid of my machine so it doesn’t entirely close, gotta put air in if you plan to suck air out. You could also drill holes in the front panel of your machine to let air in, and some machines come that way. With good air flow across the work you shouldn’t have much settling in the head (maybe over some time, but minimal).

Air assist setup I’m using, two solenoids and a small valve to adjust the tiny bit of air I use when not using true air assist:

Left solenoid wired to “status” pin, right solenoid wired to “wind” pin.

New lightweight head and #2 mirror mount:

Dan

Yes, it’s not the oil you can see, it’s the gunk inside the rail blocks with their myriad tiny ball bearings.

Even counterfeit HiWin rail blocks should have an oiling point, which you can use to blow out old muck and relube. I tent to give it a bit of mineral oil, a blast with air to blow it clean, then re-oil.

Lithium grease doesn’t dry out and tends not to migrate much, so you can wipe and re-apply, giving it a clean in the process. The mineral oil just lubricates the balls in the bearing blocks.

Even if you haven’t got hiwin, their lubrication instructions are great: https://www.hiwin.com/pdf/lubricating_instructions.pdf

this is such valuable information Bo

thank you for sharing it.

i’m going to change my workflow.

Very welcome.

A couple of points - unless youre making really dirty stuff (like metal cutting or lots of plastics), if you use lithium, you shouldn’t need to clean as often. I recommend a twice yearly wash-down, relube. If you’re running two or three shifts a day, doing it monthly.

Phenolics like Traffolite, aren’t particularly difficult from a lubrication perspective - but the little bits can cause the balls to rumble and stall in a CNC router implementation. A wipe down with a greasy rag after a shift is wise when lasering, as it will build up on the surface of the lithium and can clump if left to build to any appreciable amount and cause chatter.

Thank you guys for all the replies. We are engraving on silicone. We have a couple of Universal Lasers and Full Spectrum these don’t get as bad as the cheap Chinese laser do in fact the I Universal is never really dirty when I check the lens.

I haven’t noticed any ports to put grease or oil in the Chinese lasers that we have.

They are usually sealed, even on the genuine hiwin, and need to be opened up and an appropriate nipple fitted

Yup, 3-1 can get pretty gooey after some time.

That sounds like a cool hobby. My mother had a very old sewing machine as well as a newer (1950-1960’s) machine that she inherited from my grandmother. I learned to sew on that machine when I was 9-10 years old (48 now). I own a current day machine and the quality is in a completely different world. It works, but compared to my mothers machine it’s like comparing beautiful handmade antique furniture with IKEA. My older sister still has my grandmother’s machine, it’s a really nice machine and still runs like a top!

Dan

I’ve got one very early machine(1930s) that, once the motor was repaired, whizzes along like new.

They over-engineered them and used quality metals.

My wife is a very accomplished seamstress and won’t use a modern machine.

It all started when the machine her mother gave her broke when we moved internationally and needed repairs. Now I’ve got a shed full

I’ve got an old New Home machine that belonged to my mom. Her dad bought it used and gave it to her when she was a teenager in the 50’s. Probably a 40’s? vintage machine. Or 30’s? Dunno.

Looks just like this one:

Well I’m definitely not an accomplished seamstress, but my wife’s Girl Scout troupe comes to me to sew on their merit badges and no one has complained🤷♂️ I made friends with the parachute riggers when I was in the military and they let me use their machines (after I could prove I’d fix anything I broke). Made all sorts of gear bags and tool pouches for the flight deck crews. I probably still couldn’t sew a shirt without one sleeve being too short, but I enjoy it when the need arises. Always interesting to see what other hobbies/businesses people have in addition to laser work…I’d list my hobbies, but the internet doesn’t have enough storage space to hold that list, haha!!

Dan

That’s in great condition, and with provenance!

I can’t see a treadle - is it electric?