Are you happy with the result and the method? Looks great to me. Well done.

Trying to duplicate this…

Am I correct with 3 tablespoons of both PVA and TiO2, then 1 tablespoon of water?

For a 3/3 to 1 water mixture?

![]()

No. That is not what I use. Here is the details of the mix I use.

I’m now using the latest modified formula. For best results with a brush on method measure out 100 ml of PVA glue and I now add 3 tablespoons of water plus two drops of liquid hand soap. Mix thoroughly. Now add one full tablespoon of titanium dioxide to a flour sift. Slowly mix sifted powered to your PVA as you stir. Make sure you mix well. I now strain this mixture through the flour sift into another vessel. Paint on clean tile as you would paint anything with gloss paint. I dry with hairdryer and laser at 1000 mm/m 80% power. 40 watt diode laser.

Thanks… Will give it a shot… I’ve doing this on my fiber laser…

Almost think it’s too ‘hot’…

Will let you know how it works… ![]()

![]()

Hi Ron

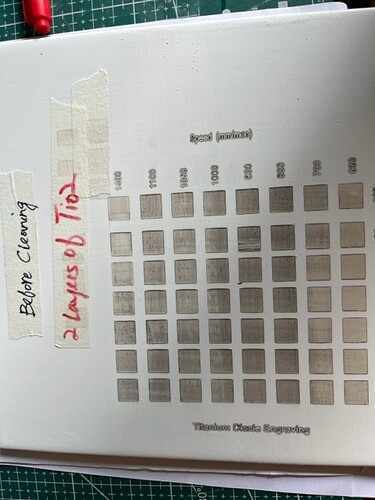

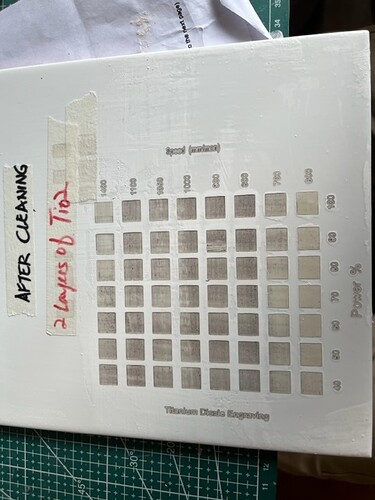

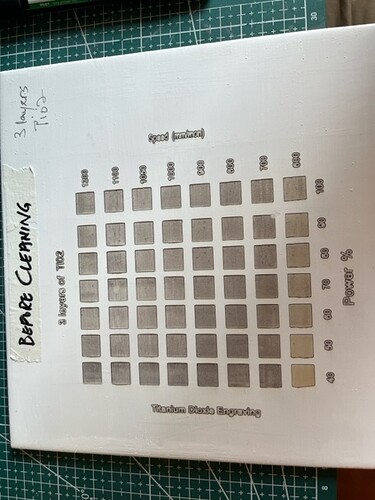

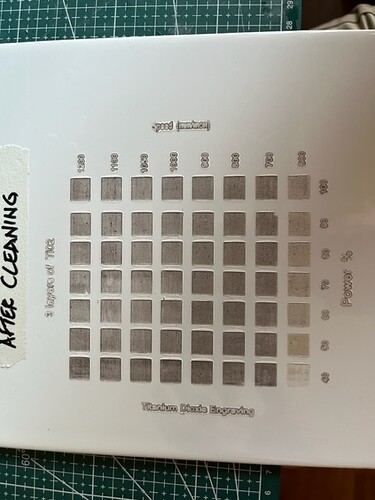

Hope you are having a great weekend. I spend Saturday and 2 x Sundays totalling more than 18 hours trying to do Laser Engraving using your latest method of mixing : 100ml PVA glue, 3 tablespoons of water, 2 drop of liquid soap mixing thoroughly. Then add a tablespoon of fully sift Ti02 powder. After mixing & stirring fully I also sifted the mixture into a container. Everything seems going the way recommended and when using on tiles the layout seems OK.

The Neje Laser Diode I’m using is 10watts with dual laser head & had to do engraving test to determined what Speed and Power is necessary for engraving. Attached are photos of tiles with 2 layers and 3 layers of Ti02 coatings. Somehow it is still not dark enough to be able to do a good engraving like what you have done. I’ve also tested with tiles coated with 4, 5 and 6 layers, but somehow it is still not dark enough. I can buy a higher wattage laser diode unless I know it can do the job, or it will be a waste of money. Although I know how to do engraving using Norton method I still prefer the Ti02 method. Anyway I have not given up yet and will try again. If you have any further recommendations it will be a great help.

Thank you and look forward to your recommendations if any. John

John I do not think we are going to resolve this problem without a little bit more information. So lets first put to one side the mix, which I guess is probably near as dam it right. I know we have different machines and the output could be different, but seeing as you are doing a test with varying speeds and power you should at least get something close to what you desire. Can you send me the test grid file you are using and the speed and power settings you are using for the text in the grid. Also the DPI or line interval settings you are using. I also do not think increasing the layers helps. I only apply one layer. Too many layers will only reduce the ability of the laser beam from penetrating the layers and melting the tile glaze. The process is to heat the titanium and the tile glaze so that they fuse together. Heating the titanium turns it black and melting the glaze lets the two mix. As the glaze cools it traps the blackened titanium and makes the marking permanent. If you are not melting the glaze the blackened titanium will not fuse to the tile and will wash off. Send me the above details and I will run them on my Atomstack and see what results I get.

John,

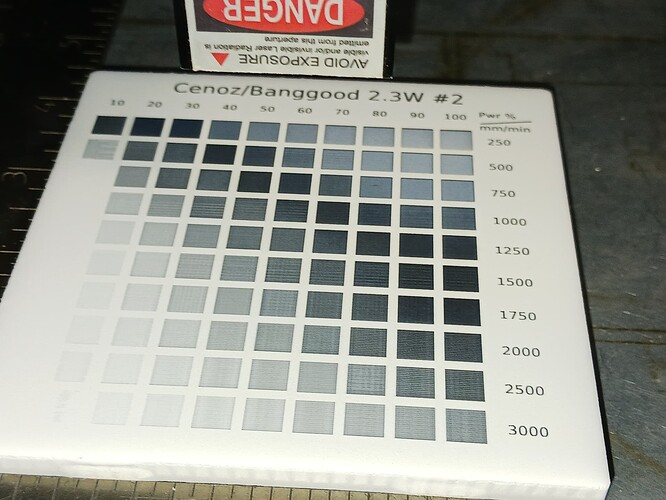

I think you are using way too much power and completely destroying the glaze… leaving the raw ceramic exposed below. I have the same Neje A40640 laser as you and it does not give nearly the good result as my little Banggood 2.3W laser…

It looks as though you’re stopping at about 40% power on your test matrix. Start your test from 10% and I think you’ll start seeing the “blacks” you’re looking for.

For reference, my 2.3W laser gives the “best black” at about 1500-1750 mm/min and 100% power…

Since the Neje A40640 (~10W) laser is roughly 4X-5X the power of my 2.3W laser… possibly you should start seeing decent blacks around 1500-2000 mm/min and 20-25% power? As Ron said, you’re trying to melt and mix the glaze and TiO2… not blow it away. Also, don’t use air-assist, if you have it… though I keep a small personal fan gently blowing across the worksurface, just to blow the smoke away and keep the lens from fouling.

My $0.02.

– David

I don’t think we are melting glass here… Might be melting the TiO2 causing it to molecularly bond to the glass or glazing.

If you could melt glass, you could cut it. We know these lasers can not damage glass directly or we’d have less need for TiO2 to be painted on the surface. Even the CO2 doesn’t melt glass but will damage it by fracturing pieces of it away…

If you attempt to heat any one point of the glass to the melting point, it will fracture long before you ever get there.

![]()

I would not argue with you regards the melting of the glaze. I’m only going by what apears under a microscope. To me someting apears to be melting, but I’m no scientist and can only discribe what I see. What ever happens it would seem that the titanium fuses with the glaze. How else would it become part of the glaze and not be removable buy scrapping. Is glaze the same as glass? I don’t know enough about it to say if there is a difference.

A glazed tile has a liquid glass or enamel that is melted onto the tile… generally to seal it…

The whole tile is heated, not just the top… If you don’t heat the entire tile it will break from thermal expansion… Same as heating a spot.

I think what you see in the microscope is the melted TiO2. As you know you can’t really lase a porcelain tile as the glass won’t absorb the led wavelength.

The TiO2 bonds to the glass, there isn’t a melting mixing operation like welding of metals…

Make sense?

![]()

Sinter is what you’re looking for…

That’s the process going on here. It’s not to the point of melting, rather bonding at the molecular level.

Sorry but no I can’t see why glaze, which you say is a liquid glass, would not melt with sufficient heat. Heat is applied to make glass molton when used in glass blowing, so would it not react the same under the intense heat of a lase. Maybe it’s just my 85 year old brain can’t think clearly. All the same this is not really the place to hold a discussion on such technical matters. So I’ll accept your superior knowledge on the process of tile engraving.

My take on it would be staining the glaze. Kind of like spilling red wine on a white carpet. Sure, you get harsh enough chemicals you can get it out, well probably just most of it.

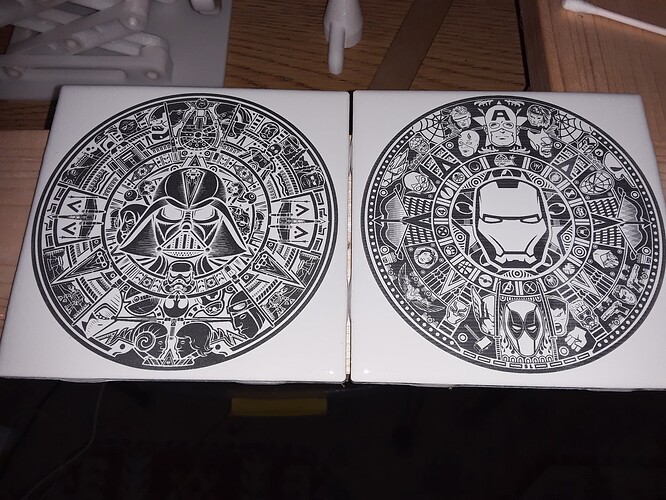

Whether “glaze = glass”, melted or sintered, or whatever… I don’t know. You folks are far more up-to-date and technically strong than me, an old man (though 9 years behind Ron at only 76 ![]() ). But I can show you what I’ve done and how I did it… even if I can’t be entirely technically correct in describing what’s really going on.

). But I can show you what I’ve done and how I did it… even if I can’t be entirely technically correct in describing what’s really going on.

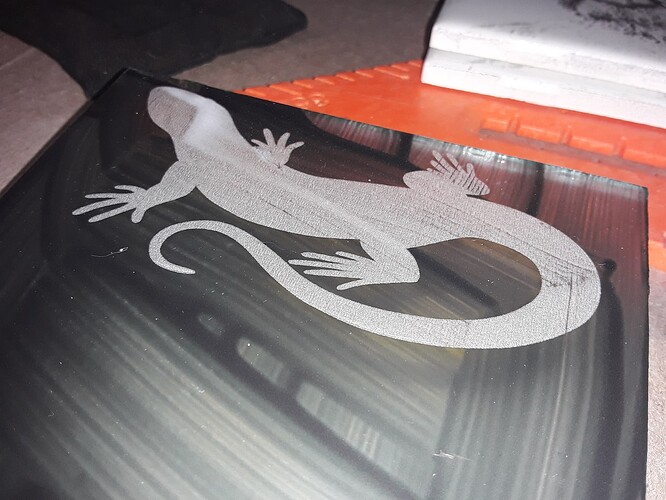

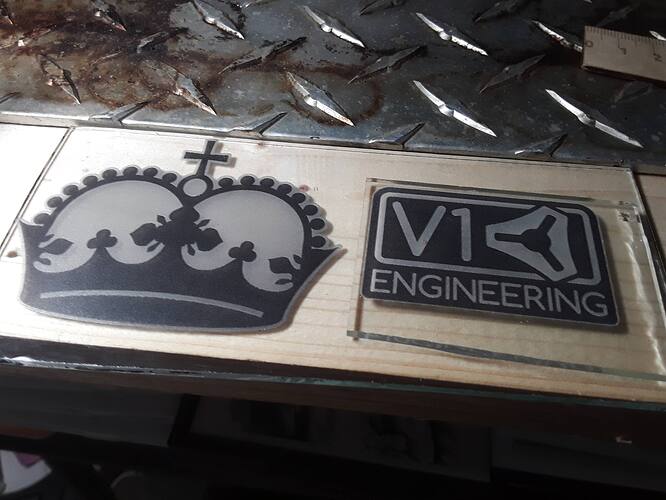

The same NWT process on ceramic tile can be used on transparent window-pane GLASS. Painted (here using Krylon flat-white spray paint)…

and, after cleaning with acetone, a fused-to-the-glass black image…

By contrast, painting with black paint (here, poorly applied tempera) and all else (power, speed, etc) being the same, the lasered image is etched (ablated?) into the glass…

Ultimately my interest is in the end product… not so much, whether I can accurately, technically describe what is going on to make it happen. So I can’t argue my position (and don’t want to try) but I can show what can be done…

Though the “recipes” are functionally similar, I know there’s a definite difference in what’s technically going on “underneath”… the black image is a raised (embossed?) image on the surface and the frosted image is a relieved (ablated?) image in the body proper of the glass.

Again, no argument here, one way or the other. Just my observations… and my $0.02.

– David

True, but it’s the whole thing… Try heating up a glass bottle and attaching a handle on it without heating all of it …

Glass is a poor conductor of heat, when you heat a portion of it up, that part expands and the other doesn’t, so it cracks or shatters. This is how a co2 laser engraves glass, it shatters it. The uneven heating shatters the glass.

I take mine and run steel wool over them to ensure they don’t end up in someones hand or worse.

If you could melt it, you could cut it… You’ve never poured something hot into something glass and have it shatter?

@dkj4linux … Your laser cannot directly engrave glass, you are using an indirect method of engraving glass by heating something in near proximity and that heat damages the glass… You can do the same with putting something black under the glass, lase through the glass… You’ll have to flip the image since it will be on the back side.

The black image is just TiO2, again, molecularly bound to the glass.

![]()

Jack, I’m not sure why you are so insistent that we understand we can’t melt or cut glass with a laser… or why we can’t directly engrave glass with our lasers. But that’s not what we’re trying to do here, either. This thread IIRC is about using the NWT method – an indirect method – to engrave tile… and Ron’s “recipes” for using “raw” TiO2 rather than commercially available white spray paint.

I’m also aware of the no-paint, thru-the-glass, method… check it out in my thread.

– David

Preach, brother!

This is not true.

We are not melting any glass (glaze) only TiO2.

Seems like you keep bringing it up ![]()

![]()

I stand corrected, Jack. I apologize for my ignorance and technical inaccuracy.