You don’t need to paint glass to get it to etch. You simply use a laser transfer tape. Once your etching is done, remove the tape and hit the glass very lightly with spinning wire wheel to remove the shards in the etch and it’ll come out beautiful. I really don’t know where this whole paint thing came from.

Link to tape: https://amzn.to/3b7zUGO

I use cold galvanize paint - has metal in it. Much easier to remove with a Brillo pad under running water that using paint thinner. Works well on white tile also.

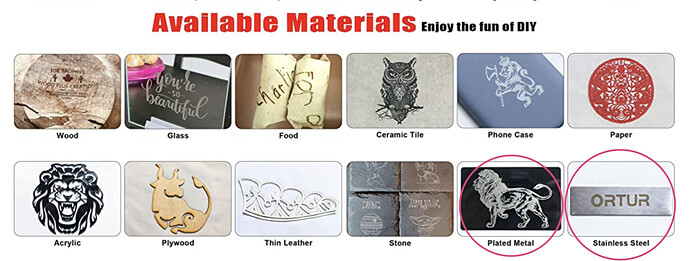

Thanks everyone! I’ll try these ideas and do some digging  Now I can’t get it to engrave metal either, even though it says specifically:

Now I can’t get it to engrave metal either, even though it says specifically:

“ORTUR Laser Master 2, Laser Engraver CNC, Laser Engraving Cutting Machine, DIY Laser Marking for Metal”

SUPER frustrated with my purchase… have only been able to do wood so far.

stainless steel marking may work, i do not have an ortur but I have done some stainless with my diode laser.

But you need a good lense and some patience as the focus is very important

color anodised or painted metall you could mark too. Testing and patience is the keyword you did not buy magic that can do it by itself.

If you want to do metal, that gets tricky. My sons have a shop with a couple of fiber lasers which engrage metal beautifully. I have a CO2 laser, and if I want to do metal, it has to be either anodized or painted, or I can use a marking spray (like Cermark), which is what I typically use. It doesn’t work on all metals. I don’t think your diode laser will do much with metal unless it is painted or anodized, where it just burns off the coating. That isn’t bad - there’s still a lot you can do, but you need to consider what you really want to do and plan accordingly for a possible future laser purchase to meet your needs.

With Stainless Steel you can use the Mustard trick. A thin layer of yellow mustard on the stainless where you will be engraving will have a chemical reaction between the stainless, the mustard and the heat. Doesn’t work with other metals.

I have engraved glass with a 20W diode laser. First painted black acrylic paint. I brushed it on but spraying would apply a more even coat. It takes a while for the paint to dry on glass. You could probably use a hair dryer to speed things up, but I didn’t. After engraving simple wash off paint with water. Also once painted be carful the paint scratches off easily. Good luck and have fun.

I always paint mine using black but any color will work. Then use thinner to clean it up. You only need to cover the area you are engraving.

Thank you all so much!

I see ceramic tile also on the list of “available materials”, and that’s another one that you probably wont make any serious mark on without applying some kind of coating to the tile first.

But when you get to that, search on this site for “norton method” and you’ll learn a technique that folks are using to do some amazing work on tile with diode lasers. (and CO2)

Just thought I’d toss that out before you get there. ![]()

Makers Mashup (youtube account) has a very simple and effective work around for this problem. its 11min long and very easy to follow. cheers.

Hi All. I’ve had a great deal of luck engraving glass using a zinc coating before hand. I can’t post any pics right now, I’m 1000 miles from home. But for the best effects on glass I tried a lot of different products to coat it with. After many failed attempts I found a product that works really well.

“Rust-Oleum Professional cold galvanizing compound.” It cleans off the engraved glass with just water and a brillo pad. No acetone or paint thinner needed. Give it a try.

It is probably etched from the back. It’s the only way that I’ll engrave a mirror. Just flip image in LB and engrave. If it looks like it’s black it was probably painted black to do the etching and left that way.

I was curious so looked up the video (https://youtu.be/s0sBeAsHyNQ).

Worth watching. I have a CO2 laser so I’ve never explored painting the glass, etc.

As for metal, I’ve used Cermark and even purchased the chemicals for DIY mix. Both turn out OK. However, nothing works as well as a fiber laser for marking metal. At least based on my limited testing with my C02 and fiber lasers.

Don

First, you have to get yourself some Gloss White Spray Paint and some Gloss Black Spray paint. One coat of each with full drying times in between. Once completely dry depending upon your laser. Set the image engrave to either Jarvis, Stucci or Grayscale. 250 DPI, .111 resolution, and 3000mm/m. Give this a try and adjust to your liking.

I have had success using a 3000mw laser etching on clear acrylic, trick was to use a black dry erase marker on the surface to give the laser somewhere to focus/index on. Just color the surface in, but don’t scribble over what you already colored in as the marker tends to smear around if you go over it multiple times.

I followed the Youtube video on etching Plexiglass. Used a sheet of metal, sprayed it with medium grey primer, let it dry. Put it under the plexiglass, and begin etching. Not too slow though, since you are effectively burning the grey paint and will leave a smoke residue on the bottom. Simply wipe it off with a damp rag.

I’ve etched glass and mirrors. For glass, put the painted side down on a material that will not absorb the heat. For mirrors, it depends on the result you are looking for. You can etch from the back of the mirror. This will remove the “mirroring” material and leave see-through glass where you etched. If you want a frosted look, paint the face of the material, etch that surface, and remove the paint. As others have said, the cold galvanized paint gives good results on both glass and mirrors since it has a high zinc content and gets quite hot where you hit it with a laser.

Remember, when etching glass, focus your laser on the material that the glass is sitting on, not the surface of the glass. The beam is passing through the glass, so it needs to be focused on the back of the glass/surface of the bed.

It makes no difference what the ad says. Some vendors also claim to sell 20 and 40 watt lasers. No such thing in a diode. 7 watt actual optical output is the best you can get staying within manufacturer guidelines. Whatever you do - DO NOT believe all that is in writing on the internet. There really are liars out there.

They have changed the listing. Or at least on my amazon it has. It now says film-coated glass. as far as I know glass very tricky. I read an article that said that engraving glass with a laser was basically the laser making tiny fractures in the glass as the heat builds up. So I can see why you would need paint ( film) to make it work. It has been said that the Norton method might work since it works on ceramic glossy tiles.

Good luck and welcome to the club!