sorry for a sort of cross post from Neje master 2s compatibility - #7 by scruffy1 but my problem is not what that was originally posted about

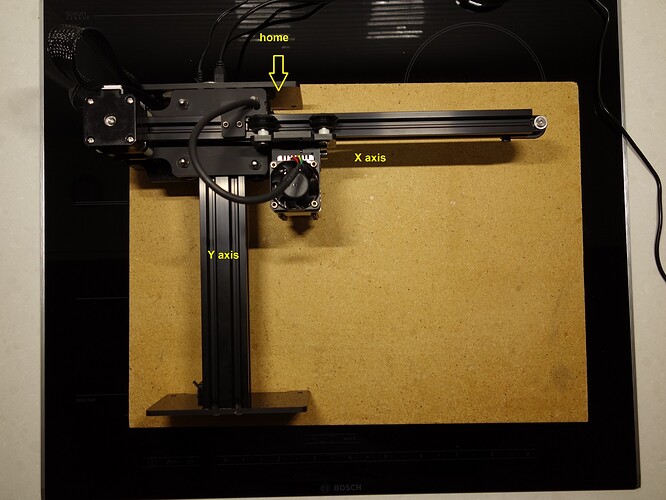

the laser responds to the “home” button by going exactly where it should, as shown below

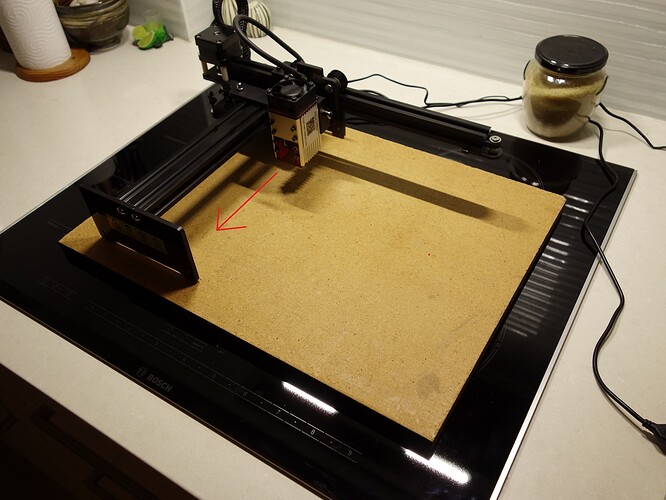

but when i choose “origin”, this is where the laser heads off to (with vile noises that i can’t reproduce in a still photo), before crashing into the barrier where the arrow points

it would seem i am in the same dilemma as the original post here : Light burn neje 2 axis problem motor noise

the crash may be because the laser module is actually larger than the original iteration of the master 2s, and the extra 1cm of space required doesn’t exist, and as such the working area has thus become truncated to x=170mm, y=160mm

the noise i can’t explain, but wonder if the speed of transit is somehow responsible, although the head doesn’t move any faster than when it is quiet framing a defined area

if i get the idea correctly here, then if the origin is 0,0 i will have to recalibrate due to the larger laser module, to accommodate clearance. and home would be (using the same relativity) actually be at 0,160

which raises these questions towards solving my problem :

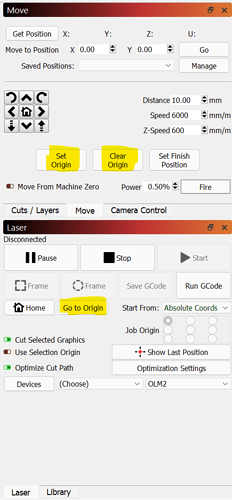

- how do i tell the console to reprogram “origin” 1cm closer to the home position so the bigger laser module won’t run out of space ? (if that’s my issue)

- why does it make the horrible noise sprinting towards what i currently thinks is the origin ?

even when i ask it to frame the project, the initial excursion to the co-ordinates makes the same horrible noise, but after locating said area, it is buttery smooth and quiet outlining the frame

under the neje software it sprints to a defined starting point without any juddering at all… and no, i don’t have both programs open at the same time - lightburn has this issue as the only program open after booting the laptop driving the device

hope that clarifies where i’m at; further assistance is most welcome

i can see the potential, and i’d love to use it