There’s a new release of the beta above - please redownload, install, and try again

https://drive.google.com/drive/folders/1NlXdR93xibmEnw625vCXf79cPITThy5u

It is now working. I had added it manually with the previous version and that worked.

I did try Find my laser and it did not. I assume that might be due to the manually added version.

Thanks!

Try the new release… It worked for me.

Hi all.

I’ve been testing the beta release for the xtool s1 for a while and so far I haven’t come across any big issues. The air assist comes on when it should it runs at full power but that’s not a problem for me. The exhaust fan starts when it should and runs on after the job is complete for the right amount of time. No sign of the dreaded triangle of doom. The actual size of the work area isn’t as big as advertised but that may have something to do with the size of the 40w module compared to the 20 or 10w modules, but for me, I can live with that. I’ve just got some testing to do with the RA2 Pro, and I’ll give more feedback on that soon.

Cheers,

Steve.

I am running 1.7 with BSL board and UV galvo.

I had a strange issue when pausing a job and then clicking stop the play button kept flashing pause/resume.

I couldn’t get the laser out of this state.

The only way I could solve was shutting down the software and opening again.

I’m finding that I’m getting really different results between my materials test and then if I put those same settings into my job.

I can easily repeat this issue over and over. It’s like my test jobs have a lot more power.

I’m noticing this both for engraving and line settings

Machine is UV 5W Galvo

Edit: this may be more to do with my laser source seeming to need to warm up before full output

The only thing that seems to be changing my sources output is Speed / and fill width.

Edit:

Output works as expected when using normal material parameters. E.g. more power when requested so seems to just be materials test generator

Material warming and starting temperature are also factors.

An infrared thermometer may help standardize results.

This is definitely something strange going on with the materials parameter finder.

If I make my own test squares the result varies exactly as you would expect in terms of power change etc.

For reference I’m testing on the 1.7 version for BSL support if that makes any difference.

This is an important distinction, as this 1.7.00 BSL support is still very much a beta. I am moving this post to the beta section to keep the information together for better tracking of issues raised.

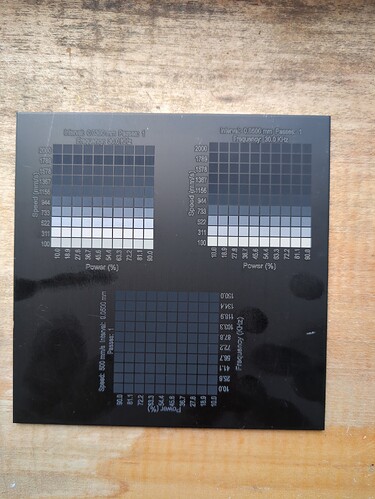

UV laser sources do not use the power % at all, so that’s going to be issue #1 for you. ![]()

They use ONLY Q-Pulse and frequency to control power output. They’re very weird.

Should I change the settings in my device then?

I was told by the manufacturer that I should leave it set as CO2?

Secondly when trying to use rotary it is not spinning during the job.

Using the test function it spins 1 revolution and back again.

Hi @Alex_Laser - can you send a Support ticket in to support@lightburnsoftware.com so we can directly assist?

I have sent in a request.

You should not leave it set as CO2. LightBurn has specific functionality built in for UV lasers - it alters the way the Q-pulse value is sent to the hardware, handles the valid range of values in a different way, and a few other bits.

Thank you for making my Mr.Carve m1 pro laser engraver compatible with your software; Seacad is a scandalous thing. I am testing your software with my machine on a MacBook Air M1 and an Asus Windows, and everything seems to be working well. The configuration was done automatically, and I provided the parameters from the Seacad configuration file. I cannot understand why the engravings do not appear in the first few millimeters. That is, the first part of the engraving does not engrave, and then it starts engraving normally. I am also testing the rotary arm, which at least appears to be moved by LightBurn. I will attach a photo as soon as I can.

With the rotary should I be able to use it both as an X and Y axis on galvo?

I am seeing the same behavior with my Seacad and EZ machine where my rotary will only engrave in one orientation

I tried only on the Y-axis and honestly, it worked on the first attempt. I haven’t delved into how it works yet, but if it runs, it’s “”“”“just”“”" a matter of settings then… I’ll continue testing and see if I have issues with the other axis.

I think i spoke to soon, ive come across an issue where the laser just stops mid burn, its happened a couple of times now.

Any new information to report? Issues like the delayed engraving fixed?