Good evening:

I have a sign shop and have added tumbler “engraving” as an added service for my customers. Currently I’m running two ortur 3 10w machines with rotory chucks. The machines do a good job of burning the material off, but the do take a long time. That’s the reason I have two.

My question is, should I upgrade to a 20w ortur module, or an even more powerful third party module like a laser tree.

The other option would be stepping my game up to the next level and buying a CO2 laser. I’d like suggestions on what a good entry level co2 would

Brand, size, wattage, etc. The laser will mostly be used for burning tumblers, but I do think I will be using it to engrave plastic corridor signs (1/16") at some point

Thanks in advance.

If it has to go fast it is a fiber laser I will use.

I’ve thought about the fiber, I just don’t know if it will pay for itself. I’ll look into them more. The ones I’ve seen have been more than my truck.

Most of the time I don’t mind them taking,30-45 minutes to get a nice burn. That’s time I can be working on other jobs. Lately I’ve been getting a lot of decent sized orders from government entities that have short timeframes.

I just figured I’d see what my options are.

Thanks for the reply. I’ll look into them again now.

There’s some pretty nice little fiber machines out there in the $2k to $3K ~20W, starting range. Probably don’t need much power…

I got rather burned out on mugs with the co2, so I haven’t any on the fiber… I’ll have to try that.

I did my lens tubes for the co2 machine on the fiber… There is some beautiful stuff out there people are doing with fiber machines.

Not all of them will allow Lightburn to control them. Don’t want a new machine and a new Chinese software package to learn.

In theory, if you double the wattage, you can double the speed… at least a good guesstimate. The machines you have, if working, may be fine…

![]()

Thank you for the response. That was well articulated so as a moron like I could understand.

I never Thought about light burn not being compatible with a different laser. I definitely don’t want to learn Chinese software. I use illustrator for everything, and lightburn pairs well with it.

Thanks again for the reply. I’m still looking at some of the fiber lasers, but I’m thinking I’ll just try the ortur 20w head at the moment.

Probably a smart move… the most bang for the buck.

That gives you time to learn about fiber machines and make a better decision if they will fit in your work flow.

I was going to post a photo of one of my lens tubes… done on the fiber.

Good luck

Have fun…

![]()

That looks amazing! If you don’t mind my asking, which fiber are you running?

Thanks again for all the help.

If you click on my user name, it shows my profile and lists most of what I have…

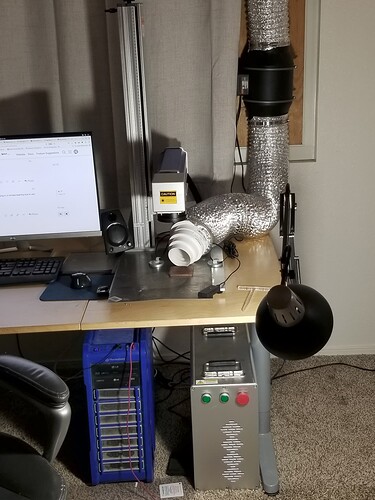

It’s a Cloudray M60 JPT M7 MOPA… Silver box on floor is the source and controller… It has an 800mm column. I have an F420mm which covers 300mm square.

@Bulldog dose some incredible images on his machine… I believe it’s the same machine as mine…

That’s only a few…

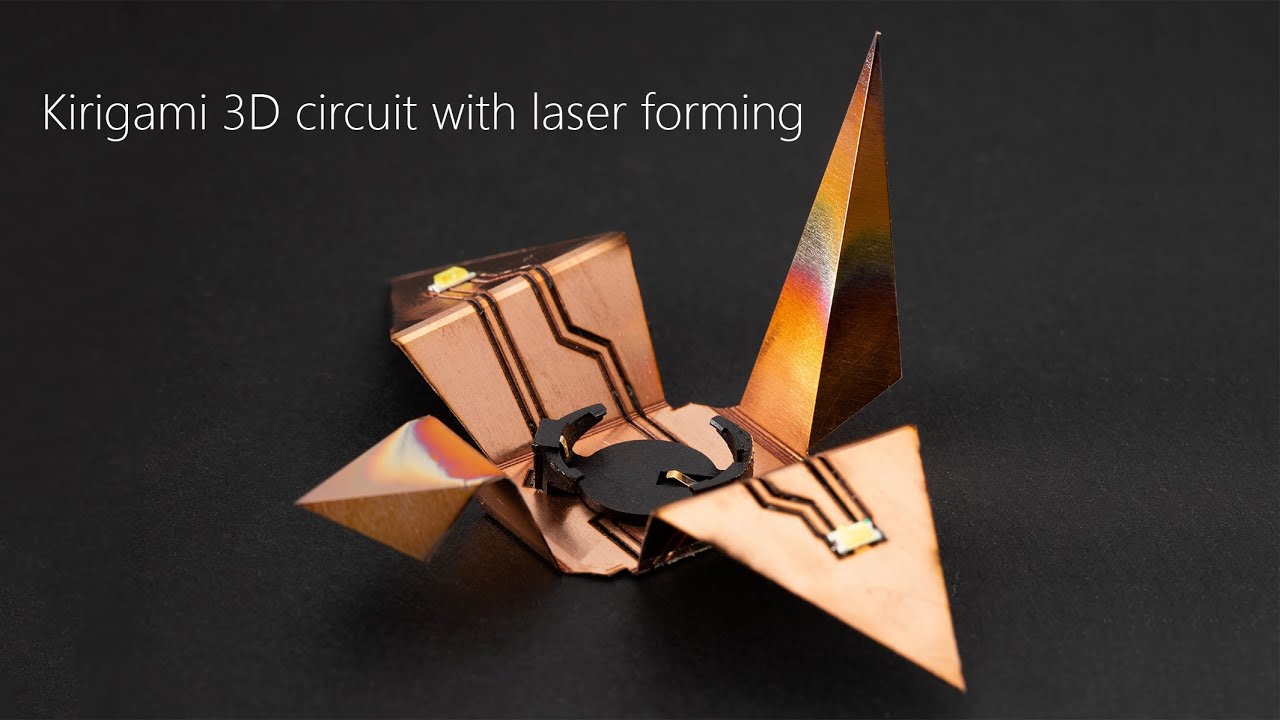

This is a neat video, never imagined doing what they do here. In the first 20 seconds they are soldering the components to the board…

Good luck - have fun

![]()

Wow that’s one heck of a setup! Thanks for giving me more information. I’m going to look into it more later today. I have to do some shop upgrades Today, but I’m sure I’ll be wanting to take some breaks. The current budget I have planned for it is $3k. I realize to some (like my wife) that sounds like a good deal of money. As we all know, that doesn’t go far with quality equipment.

Thanks again.

When I got my fiber, I had an acquaintance that has had a commercial fiber for about 5 years. I think his is built in the US or at least one of the western countries.

He concluded I have at least as good of a machine as I do… I paid $7k for mine, he paid $70k and has to run their software…

Deals are out there… it’s best to at least ask here first … might save you some money and headaches down the road.

Good luck

![]()

If you happen to live in the Utah area I may have a fiber laser you might be interested in. It will be local pickup only

I will not ship the laser.

Thanks for all the helpful advice guys. I think I’m going to try the 20w module on one and see how it does.

I wish I lived in Utah. Unfortunately I live in commiefornia ( closer to Oregon, but still commiefornia.

Thanks again for all your usual advice. This is by far the best forum to ask questions on.

Be aware that moving up to a quad diode (20W) will increase your spot size, so details might become more difficult. Depends on your designs/sizes/expectations. I started with a 20W and had to add a 5W for more detailed work. About the best I can get out of my particular 20W is a .09mm interval on hard materials. Just FYI.

Thanks for the info. Most of my designs are low in intricate detail. Part of the reason it’s taking so long with my current machines is that I have the intervals set to .05 to get the cleanest burn. I do multiple passes and they come out very nice, id just like to have a bit more speed on last minute jobs.

I’m only going to convert one of the machines at first to see how I like it. I figured I can always put the other module back on if the job calls for it.

Thanks for the advice. I really appreciate it.

Might be just the ticket then! Defocus a bit to soften the edges or run an outline pass to remove the “jaggies” and you should be able to more than double your throughput. More power for a faster speed plus half the number of scan lines…

Thanks. I’m probably going to order the ortur 20w today. I’ve been looking at the laser tree stuff, but would like to keep everything the same brand for ease of compatibility.

Thanks so much. You’ve been a tremendous help!

Well just to let anyone who’d like a follow-up on what I decided to do. I purchased a k30 for one of the machines.

Thanks again for all the knowledge and help. I’m sure I’ll be back to annoy you with more questions.