DSP Ruida RDC6445GZ (Firmware RDLC-V15.01.27)

My machine is setup for a y-axis swap (not driver for a U-axis). not looking to add that just yet.

I would like to be able to use LightBurn Software with this 6445 control panel.

It is compatiable with LB, which is why I bought it but I cannot get the control panel to respond properly to tests with rotary enabled.

I have read this thread on how to use LB with a 6445 on /U/-axis. But I am trying to use it on the Y-axis.

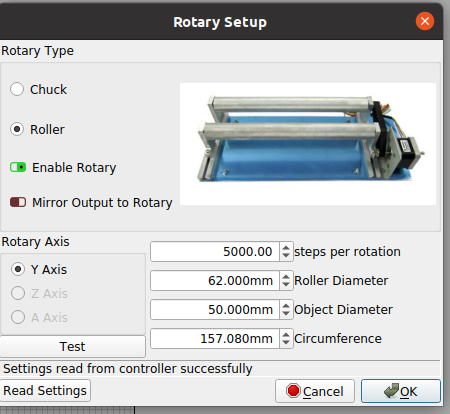

I have both a chuck and a four-roller style rotary, and trying to setup the four-roller.

I am clueless on how to setup rotary attachments, or what I need to do to make it work.

If it were as easy as putting in the diameters, I think I could get it done, but it is not that easy.

When using rotary setup: enable rotary goes green… read settings, that works…

ensure head is located and LB settings are set to ‘current position’ (thats a check).

HERE is where it goes wrong:

I hit the ‘test’ on rotary setup screen, and it moves the X-axis just a bit… rotary axis does not move. WTH?

What are my options here guys and gals?

THANK YOU!

edit:

I was able to get by using a video for how to setup using a K40 laser using the Y-axis as a rotary… I mean… sure it works technically… If you don’t mind calibrating it every time… oh and shrinking the image in the Y-direction by the % needed, so it engraves correctly… In one case it was a scale factor of 21.8% and in another case it was 22.2%.

So changing the settings via rotary setup does not seem to change anything with the laser. I hit ‘ok’ after rotary setup, and then use move command in Y axis, and it does move the rotary. The issue may be that Lightburn must think my rotary is on the U-axis of this controller. but it is not, it is not, it is the Y axis. This theory is proven out by changing the number of steps per rotation in rotary setup, and verifying it does nothing to the scale of movement in the Y axis.

If I don’t setup the rotary, and just let the laser run the rotary as if it were the Y-axis stepper, it obviously accelerates and moves waay too fast for a four-roller setup and just throws off the cup/glass. So that is something else I had to learn – lower the idle movement speed and between line speed down to 20 mm/sec. save settings. then when done suing rotary, reload old settings.

but I paid alot of good $$ for this equipment to work right. Seems like I am missing something important… would be great if I could just input the diameter of my workpiece and have lightburn engrave to the correct scale…