Of course! ![]()

Do not drag the kerf width into the axis calibration fight, because they are not related.

Opinion: folks who tell you to calibrate the axis based on cutting any material do not know what they’re doing. Engraving vector lines is OK, but it’s even easier than that.

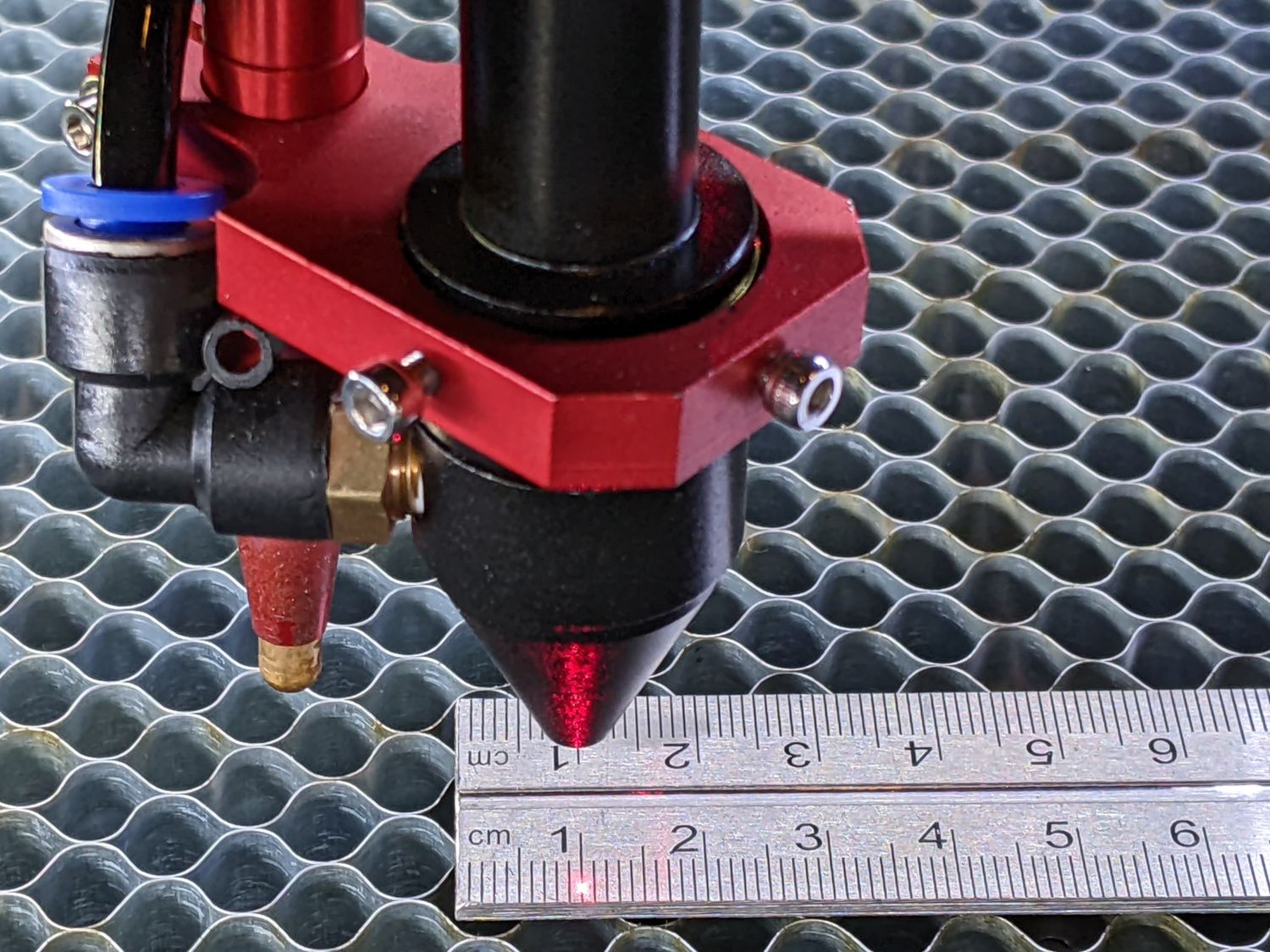

Instead of wringing your blocks, deploy the longest bestest engraved metal scale from your armory:

Align the scale parallel to the axis, align the laser (with its red dot pointer or test pulses) at a convenient division, jog a known amount, and see if the beam is dead on where it should be. If not, tweak as needed.

In principle, the step/mm (mm/step or µm/step for Ruida controllers) is not amenable to tweaking. The stepper driver gives you the step/rev, the pulley gives you belt teeth/rev, the belt pitch gives you mm/tooth, and there’s nothing else to know.

I am unconvinced the tweaks mentioned in that blog post meant anything, but at least I confirmed the machine is calibrated well enough for all practical purposes.

In order to measure the kerf, you must cut something and measure the result. The tool described in this thread works well:

You can find other such tools, any of which may become your favorite.

You must verify the kerf in each material and maybe each thickness, because it will differ: acrylic might be 0.15 mm, chipboard 0.2 mm, and EVA foam 0.6 mm.

With the proper kerf in hand, you can offset whatever shape you’re cutting by half that width to make the finished part come out right.

The size will be correct regardless of the kerf, the kerf will be correct because you measured it, and your parts will fit because you’re fussy enough to care about the details.

![]()