I’m mulling over getting silent compressor to replace air pump. Looking at the lauded Hyundai type silent compressors, but cant run anything too powerful (wiring in the shop).

Some compressors come with one motor/pump but small tanks (25l tank, ~700w pump).

Would it keep up with cutting duties with small tank or do i need to look at bigger tanks (100L+)? Shop is small, cant just plop down 200+L tank here… Also, since it is small shop i dont want a noisy beast sitting here, hence silent type… Any silents with bigger tanks and only one pump and will it keep up ?

Silent air compressor? You will not find a silent air compressor.

I’ve just ordered a 50l silenced air compressor (XCORT brand). I was tossing up over the 30l, but decided saving $100 wasn’t worth the risk of it running out of puff halfway through a job.

It really depends on how long your jobs take to cut, and how long you wait between jobs for tank recovery.

One important point; make sure it’s an oil-free compressor. That air rushing past your lens needs to be clean.

I recently purchased this Emax compressor and it is working quite well. It is not completely silent but a lot quieter than most compressors. It also has a small footprint and at the 8+ cfm it is able to keep up with the air assist needs of my laser. It can be found online for under $400.

https://www.homedepot.com/p/HULK-POWER-10-Gal-2-HP-Portable-Electric-Powered-Vertical-Silent-Air-Compressor-HP02P010SS/302691861

Hi

I use exactly that, a Hyundai Silenced 24ltr air compressor. It’s dedicated to my laser and is very quiet.

Its the 750W/1 HP 5.2CFM version and at 1 to 1.5 bar it kicks in after a minute but does catch up and turn of, then a minute or so later kicks in again. At 2bar is keeps up for 15 to 20-minutes that I know of as that’s about as long as the longest cutting job I’ve had.

So far very happy with it.

Upgraded from a 24ltr to a 50ltr, thought it would keep up, big mistake. Go for the 100ltr at least, my Hyundai silent oil free 50ltr runs almost constantly on 20psi jobs.

How big is your nozzle? >5CFM with 20PSI is a lot of air to blow away sub_mm dust.

I think you must have a problem with that 50 lltr model. That’s a 11cfm compressor. When my 5.2 cfm is running at 2bar (29psi) it’s not quite keeping up but never drops below the 2bar. When the air assist cuts off the compressor receiver is back up to full pressure and turns of after a minute or so.

The nozzle is about 3mm across, I run 20psi when cutting 6mm ply. I fill the the tank before I start the job but 5 minutes in and it’s on and off regularly.

Ok. So you meant ultra quiet. I am aware of the noise suppressed compressors, but many of those (including the one linked in the post above) are still very far from silent.

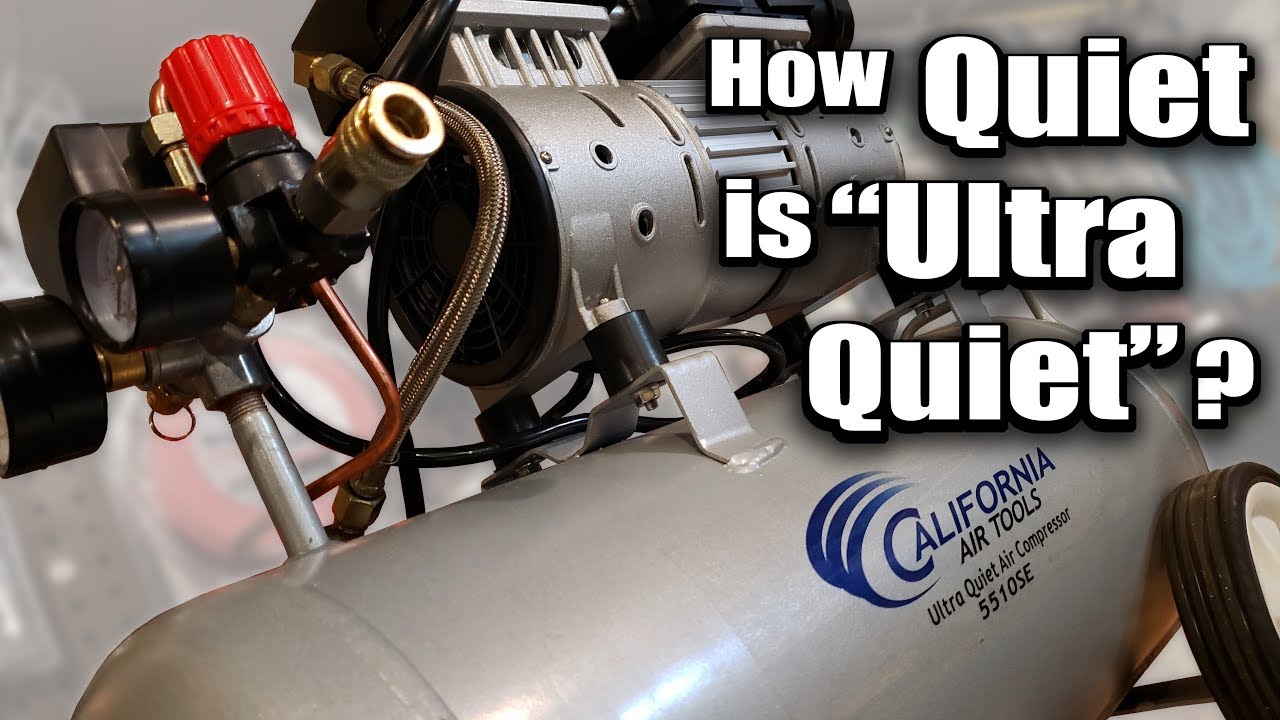

I have seen videos of the California Air Tools Ultra Quiet Air Compressor that really impressed me. I’d say that it is no stretch of the imagination to name this compressor “Ultra Quiet” .

The compressor itself look to be identical to my Hyundai one.

It is extremely quiet

The air needs to be dry.

… and blowing that air on your lens.

Still, if your air supply is sputtering droplets of water onto your cut line, you may have issues with your cut quality.

I’ve been using a California Air Compressor for several years on a small CNC mill for a power draw bar and for Fog Buster lubricant dispersal. The Fog Buster only needs 20-30 psig but the drawbar needs to run at 100+ psig discharge pressure so that’s where I have the compressor discharge set. I use it very intermittently, perhaps a few times per month for several hours at a time and I’ve had two failures so far, one in the pressure switch and another in the pump itself. The company told me that these are not intended for continuous duty, which might be a problem if you are running a business. The assembly itself is fairly easy to service and I had no special problems replacing either the flow switch or the pump itself. I have noticed that the pump gets a lot noisier as the tank pressure exceeds 50 psig, but that may not be a problem for only laser use.

I had exactly that problem. Water in the air lines. I live in Queensland Australia, and the air here can get really humid - up to 100% humidity at times. Anyway, I managed to get water on top of the lens (about 1mm thick) and started to get vaiable  results.

results.

.

I was talking to Russ Sadler about it and he told me to forget about using the big air compressor, just use the putt-putt one that came with the laser. - So I did, and all is good now.

I have slung it under the laser on a couple of bungee cords, and I can barely hear it.

More isn’t always better.

Consider putting it outside. Compressors do explode. *AIR COMPRESSOR WARNING* - YouTube

Air bags deploy sending shrapnel, lithium ion batteries spontaneously ignite, car ignition switches melt down and combust, steering wheels fall off of the steering column, battery packs on electric vehicles cause massive recalls because of runaway reactions, Diesel engines can runaway and self destruct, and if you cross your eyes or make that face too long you will get stuck that way.

Edit: don’t forget that laser light causes permanent eye damage.

(But I do keep my compressor in an adjacent compressor shed for the noise).

Drain and maintain.

In fifty odd years of working around compressors, I have never seen or know of one that blew up. Putting a compressor outside in a humid environment will compound the difficulty in getting dry air to your tools.

Hi, I recently bought the Hyundai super silent, same as David L above and it works great.

Depends on how quiet you want it.

Able to talk over it without shouting.

Yes it does.