There are two big problems:

- LightBurn does not support a two-axis extension table for galvo scanners (this function is implemented in conjunction with EZCAD2 by the SplitMark2 plugin)

- Few controllers support the use of two axes simultaneously, which reduces the number of devices that can be used this way

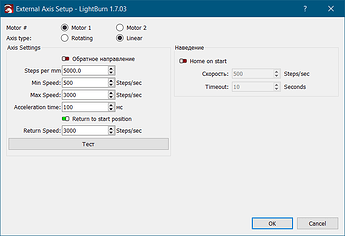

Within the first problem, LightBurn has a solution for working with rotary devices, which is the first step in implementing a full-fledged single-axis table. In addition, LightBurn has long been able to control classic two-axis lasers.

But the second problem, unfortunately, makes it pointless to develop a TWO-axis machine for Galvo, because few will be able to use this function because most lasers are equipped with the cheapest control boards that do not support two X+Y axes.

Potentially, this problem can be solved even with just one axis - signals for X and Y control can be sent using the same output, you just need to split them into “portions” - separately for X and separately for Y.

OR

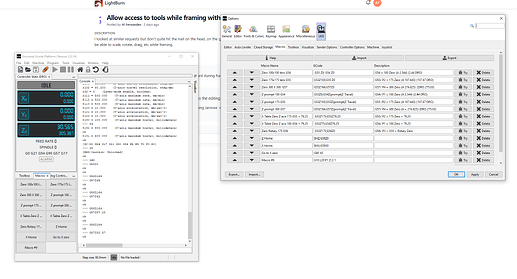

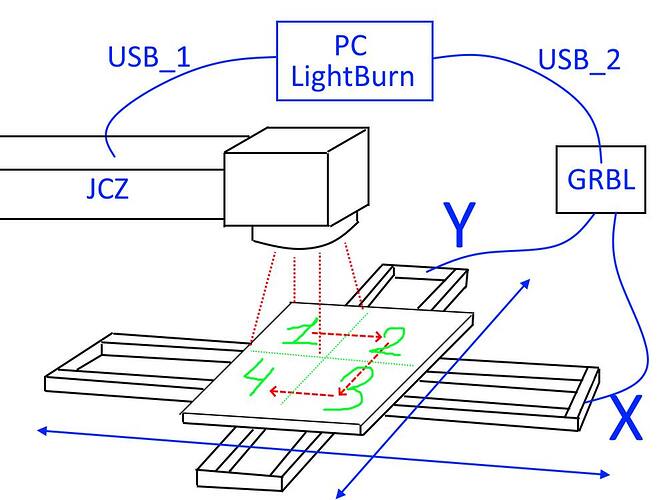

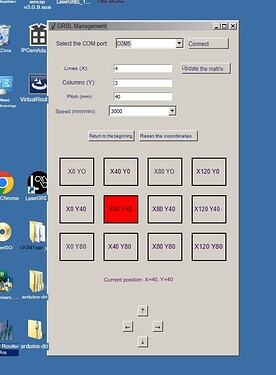

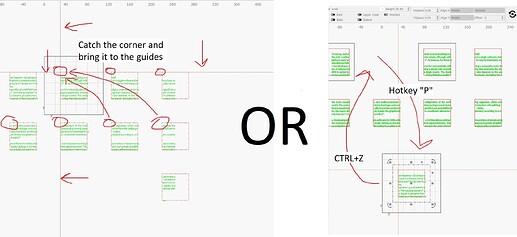

You can simply control another separate device (based on GRBL, MACH3, etc.) and make a software split: first a series of signals for the X axis, then a series of signals for the Y axis, because there is no need for diagonal movements on such a machine (the working area is divided into a grid of 2 * 4, 3 * 6 separate segments, to which the machine can be positioned, you need to send only a few coordinates - 2/4/8, depending on the settings and table size). Thus, all that is required from LightBurn is to make a micro API / console / record in a file of Gcode control commands (for example), which could be used by a third-party controller and would allow moving the desktop in the desired direction. And, of course, it is necessary to solve the problem with the correct movement of the laser machine taking into account the error and the selected processing segment, as SplitMark2 does, because galvo lasers do not work with a point, but with entire areas (70 * 70 mm, 110 * 110 mm, etc.)

In the simplest form, I see it like this: LightBurn generates control commands for an additional USB controller, the controller reads them from the buffer / file / API channel or receives them directly via USB, the desktop moves in the form specified by the command (which has long been supported by LightBurn), engraving occurs, then LightBurn sends the next batch of commands to move the table to position “2”, to a new place, and engraving is performed again, after which the movement to position “3” is carried out.

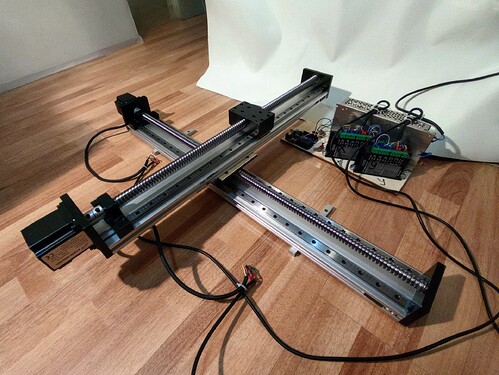

Perhaps this is too ambitious for the LightBurn team, but it would be a truly unique offer on the market - a controller that can solve this problem on its own would cost at least $500-700 (just because of the extra axis, I’ll have to buy it for work), while the quality of the EZCAD2 software that I’ll have to work with is unlikely to satisfy anyone. A controller for EZCAD3 would cost more than $1200. And that’s without taking into account the mechanical components. If you follow the described approach, it is enough to buy or use an existing two-axis machine (I know that almost everyone has a machine that they started with ![]() ) on MACH3/GRBL ENTIRELY for $ 100 and get a function that only expensive devices can boast of

) on MACH3/GRBL ENTIRELY for $ 100 and get a function that only expensive devices can boast of

Perhaps someone already has such developments - then I would be glad to learn more about them. As far as I can tell, Albroswift is a user in this area – it would be nice if he has something to say about it

Here I saw a note on this matter, but the discussion is already closed: