I’ve posed these concerns before, but not in the same light. Originally I thought it was just my CO2 but I’ve noticed the behaviour on my diode as well now. Not all, just the framing problem.

Just wondering if anyone has any suggestions as to where I could start investigating. This is really driving me nuts and I don’t know where to go now to be honest. Likely multiple problems, but hoping it’s all related.

Symptoms:

-

On both lasers my frame command is reversed. It’s a crapshoot depending on the day. One day it works normal (rubber band vs. extents) trace, next they are reversed. Nobody I’ve talked to has ever encountered so I’m just adding this in hopes that someone with good knowledge can connect the dots for me if they all happen to be related. Previous post here: Frame commands reversed and cannot get the rubber band to work properly

-

I’ve abandoned my rotary unit on my CO2 which sucks, there was just too much inconsistency, costing me a lot of money with Yeti’s.

Steps per rotation setting I don’t think should ever change once you know the value for your unit. Mine has to be checked each time doing a test burn. Very erratic

issue. I send my program to the laser (with rotary) and it does one program, send it again and everything can be completely skewed. If you look at this article, it will explain.

Odd behaviour of rotary, also not following conventions

Does steps per rotation change from part to part? -

Once in a while (most often when the rotary is attached, but not always) my gantry runs into the right side at the start of the program when I hit frame and keeps trying to go that way until I hit the e-stop. If I don’t the belt starts skipping over the teeth of the sprocket until I shut it down. Reset and everything is normal. I wired up a selector switch and added an additional connector so that I wouldn’t have to keep disconnecting the Y axis each time I wanted to use the rotary. Wondering if I connected to the wrong source for power and this is somehow influencing this? . Also the power on button has a weird electrical pop/fizzle sound once in a while, but heck I can make the light switch in my bathroom do that most days so probably nothing there.

-

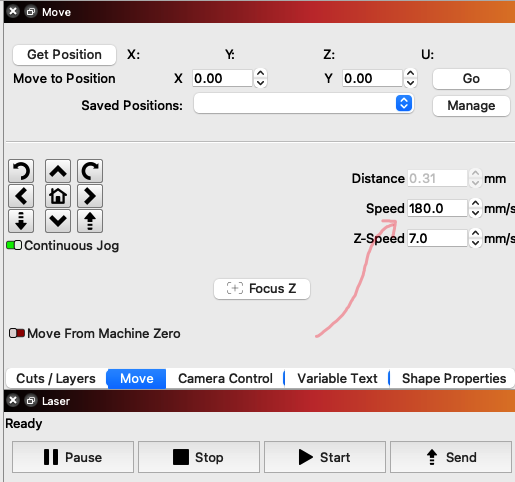

The latest issue is when using my Lightburn camera to line things up, then I frame, I can tell something is off. (This is NOT A CALIBRATION ISSUE, if I shut the whole system down, it will reset and everything is back to normal, pretty sure it is the resetting of Lightburn that corrects it). This is an intermittent problem, doesn’t always do this. When framing my image, what I would expect actually is shifted say 1/4" north (not always, just an example). So I assume the camera is out of calibration so I ignore the picture and trust the frame, I put the piece down on the bed and sure enough, it runs the laser in the path of what looked correct on the picture from the Lightburn camera, not the frame.

-

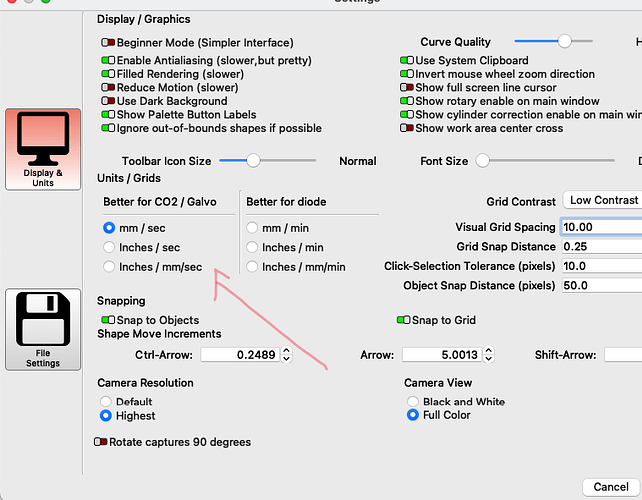

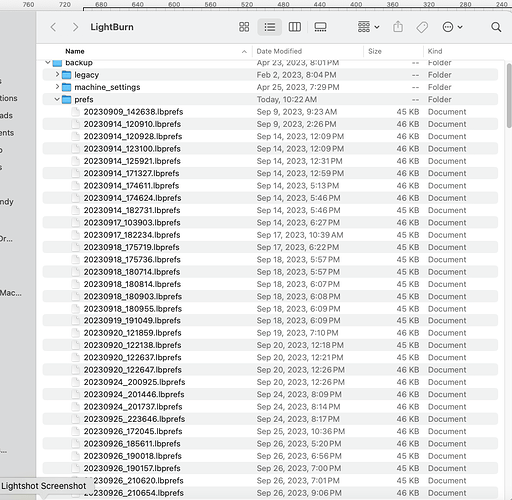

When I shut down my Mac and turn back on, it sets the units in Lightburn to Inches/ mm/sec. I never use these units. It’s always mm/sec for CO2 and mm/min for Diode. The reason I know this is happening usually is because my gantry, when trying to jump to a position, moves at a snails pace. Somehow Lightburn has rest my units. Another giveaway obviously if I didn’t see it first, is the speed units in my layers are screwed up and totally not what I expect them to be.

@lightburn, I’m wondering if you have any suggestions on #4 and #5. Pretty sure this is out of my control. I’d be up for drastic things at this point like starting a fresh install and abandoning all my settings or something. Any suggestions?

I’m honestly wondering if I would be best to hire someone to come to my place and look at my entire system. I know it would cost a ton, but something needs to be done. I’m across the border from Detroit if anyone knows someone good. I’d also be happy to give a reward to anyone that finds the magic bullet for these issues, though I doubt they are all going to be rectified together.

Additional info.

I’m running a Mac mini (which honestly seems to behave erratically itself it seems but it behaved this way when I had a Macbook so I’m pretty sure it’s not that), so my ports are limited, so I’m using a USB hub which my Ethernet is connected to for my CO2, but my Diode is directly to the Mac. Also I changed the motherboard of the CO2 thinking there was something there, nothing though.

My kingdom for a solution!

Thanks if you’ve read this far.