Thanks for the help BTW

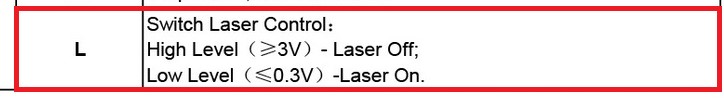

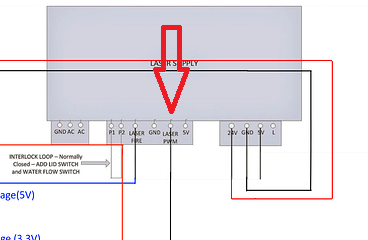

Ok So maybe most of my confusion is about which pin naming and which PSU pins do what… I notice in Yassin’s original image, there is nothing connected to L at all.

It was my understanding (and how I had it working in Marlin) that:

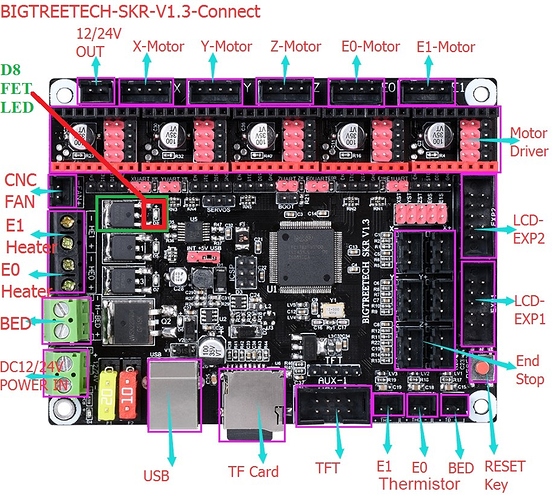

SKR - LPS

PWM -> IN

ENable -> L

Is this wrong? I just spent an hour going over tons of old posts. Some mention controlling power via PWM signal on L and holding IN at 5V. Some have It connected the way I did, Some have “Laser Fire” connected to En as Yassin did. Now I think I may have been doing it wrong all along.

In our current discussion, It says in one comment to connect PWM from MCU to L and another comment says to connect to IN.

Even more lost than before. This whole time, I’ve been using IN to control power level and L simply at 3.3 or GND to enable and disable laser.

So IF I’m understanding you correctly “Laser fire” (I assume is k- or k+ on mine since I don’t have a pin labelled “fire”), and THAT pin should be connected to whichever pin (2.3 in this case) I use for PWM out of the controller board. Then the other pin which is labelled as “PWM” on Yassin’s drawing os the LPS, actually isn’t pwm, but just high/low enable switch from the controller… Am I even close yet?

So the FET should be connect to L, NOT “in/pwm” correct? And use that pin as PWM in Smoothie config, then connect Smoothie Laser_fire pin to the “laser fire” pin. This leaves nothing connected to “IN” in my case.

Is this correct?

MCU - LPS

Pin2.3 - L

FirePin - Laser Fire

I guess the question is, Which pin is “Laser switch control terminal”?? I have a rough understanding of how PWM and duty cycle works as far as varying a signal and that the lower the voltage, the higher the power on the laser… I just need to know WHERE to put the PWM signal and where to put the On/Off Signal since it sounds like I had it all wrong.

Which Pin does “fire” connect to on this LPS? And do I Leave the In pin disconnected? I know this is a super simple thing, I just don’t know and cant afford to buy replacement parts from guessing haha

Ignore the crappy soldering, it’s temporary LOL

Edit: OMG I just noticed there are TWO “L” pins The one I have as k-, also has a label showing L, that I never noticed until I sent this photo, The Blue one on the far right is the L pin that I’ve always used.