rsx2007

October 2, 2025, 2:33pm

47

Will try test button when will be near laser

I loaded cor file that came with EZCAD software when i added bjjcz device along with all other device settings.

But ok, will try to set correction manually.

But very strange, that while using rotate marking, such problem is NOT exist…

Aaron.F

October 2, 2025, 4:08pm

48

Measure the current state first. → Engrave a square of 100mm and measure. I claim it will come out more like 9.5mm

If your scaling is off, the problem did exist in rotary mode too.

It “worked” in rotary mode because of the small splits of 5mm. The splits moved the linear axis precisely 5mm. But the engraving was still squished due to the wrong scale.

1 Like

rsx2007

October 6, 2025, 7:24pm

49

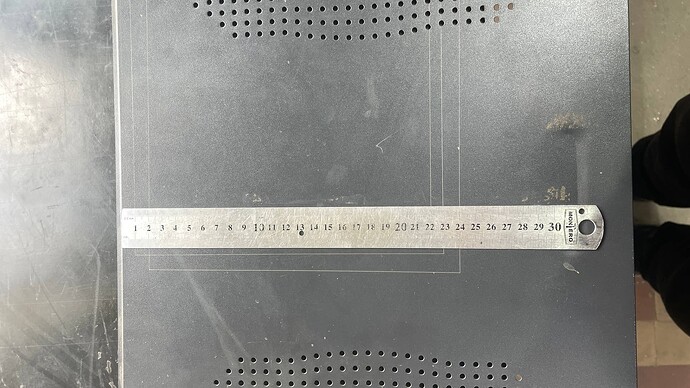

Here’s a test of movement with Repeat Marking .

1 Like

Aaron.F

October 7, 2025, 11:35am

50

That confirms (again) that the Steps per mm are correct. Thank you.

Did you get a chance to measure and adjust the scaling?

rsx2007

October 10, 2025, 8:48pm

51

Have no time and material to test big sizes (sorry), but here some small size info:

10x10:

All looks like almost perfect.

25x25:

Here we already got some shift of approx 0.10-0.15mm

35x35:

Here a bit more - approx 0.25mm

50x50:

and here is approx 0.4mm

Aaron.F

October 11, 2025, 1:28am

52

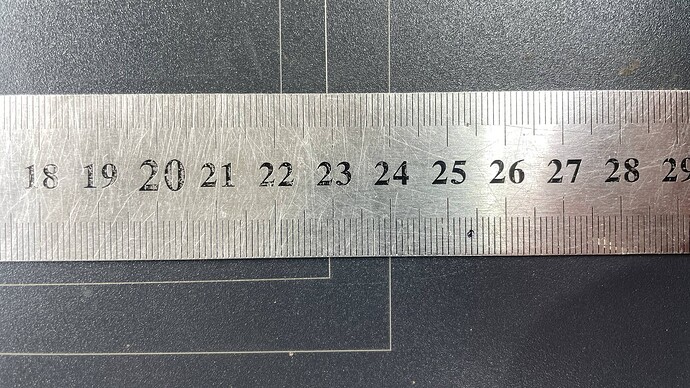

It’s hard to see, what you’re measuring, if you don’t start with 0.

The difference increases with greater distances.

1 Like

rsx2007

October 14, 2025, 3:22pm

53

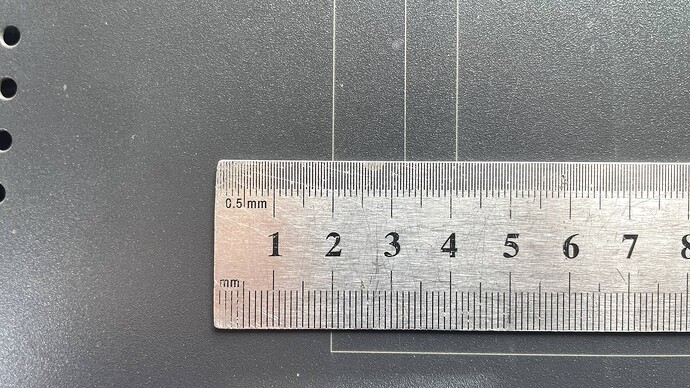

First of all, it’s important to note that the starting point is the 2 cm mark .220 mm .

Start:

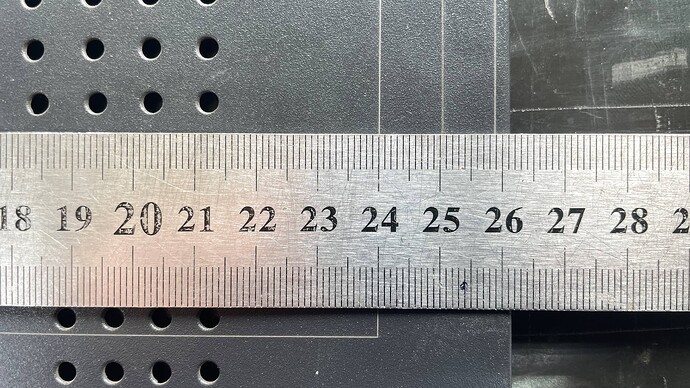

Finish:

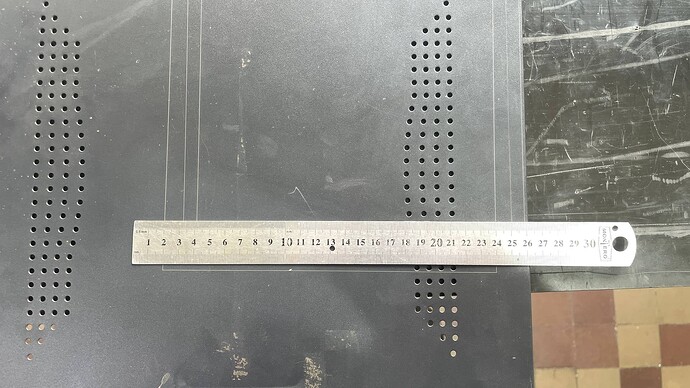

Entire area:

Y axis is perfect.

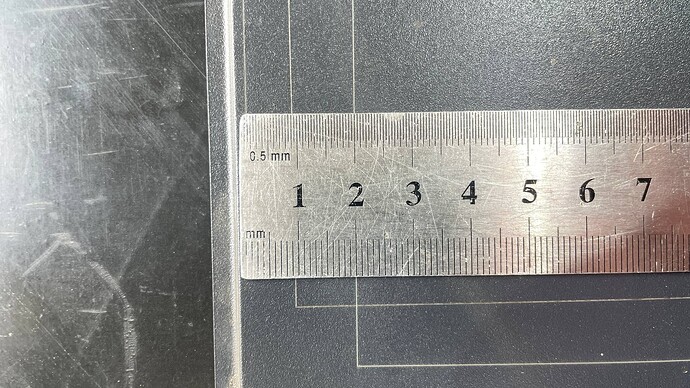

Start:

Finish:

Entire area:

The ruler here is centered, so there’s a small 1 mm difference across this working area (22 cm).

There was also a slight bulge, so I made some adjustments:

However, the result is still not valid — there’s still some issue present:

I don’t understand what could still be wrong…

Aaron.F

October 14, 2025, 3:44pm

54

rsx2007:

Y axis is perfect.

Nice!

rsx2007:

X axis

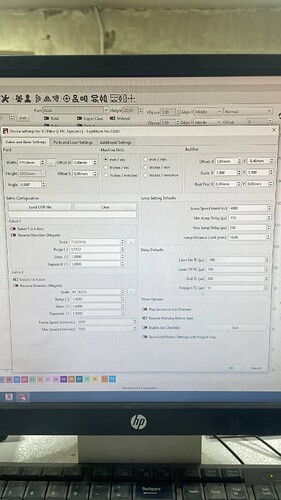

Did you adjust this by calibrating the Galvo scale in the Device Settings?

rsx2007

October 14, 2025, 4:46pm

55

Yes, and test mark of ruler is the result of marking AFTER calibration.

Aaron.F

October 14, 2025, 7:13pm

56

Was this measured before, or after calibration?

As far as I can tell, it’s almost a millimeter off.

rsx2007

October 14, 2025, 11:42pm

57

On this image if you treat it from 1 to 23 cm → so yes 1 mm off, i mentioned that earlier:

The ruler here is centered, so there’s a small 1 mm difference across this working area (22 cm).

But 1mm for 230 is pretty much small in comparison with 1 mm per 10 mm (each repeat element) as you can see on ruler.

Aaron.F

November 5, 2025, 3:03pm

58

For your convenience, we increased this limit in the PreRelease candidate of an upcoming version:

Existing Feature Updates

Increased galvo rotary size limits to 20 meters

The second release candidate for LightBurn v2.0.05 is now available to download here:

1 Like

Aaron.F

November 5, 2025, 3:08pm

59

It shouldn’t be too long before the aforementioned genuine “Split Marking” is publicly available. This should make setting up a linear table much easier, in contrast to the rotary function, which serves a different purpose.

1 Like

rsx2007

November 5, 2025, 10:43pm

60

Thank you!

1 Like

Albroswift

November 6, 2025, 2:03am

61

I see the split for rotary is way over my biggest lens now as well. What is the difference between that and split marking?

rsx2007

November 6, 2025, 2:45pm

62

Well, we tried to test it, but still we are limited to value of “steps per rotation”…

Our motor got 1000 steps per 1 mm, it means for 5 meters we need 5000 * 1000 = 5 000 000.

Aaron.F

November 6, 2025, 6:02pm

63

Split Marking will basically be the same as Rotary Marking, but made specifically for flat linear tables.

Aaron.F

November 6, 2025, 6:17pm

64

I see..

Can you decrease the Microstepping value of the stepper driver? / What’s the current division at?

1000 steps per mm sounds like a whole lot anyway.

Albroswift

November 7, 2025, 2:07am

65

Mine is 320 steps per mm. That still only gives 3.125 meters if there is a 1,000,000 step limit. (which is plenty for an X table but not for your traveler)

Aaron.F

November 7, 2025, 3:10pm

66

You can theoretically set the circumference and the steps per mm 1000 times lower and achieve the same result.

![]()