We have a 100w Prytec 1060 laser, I am having an issue while cutting.

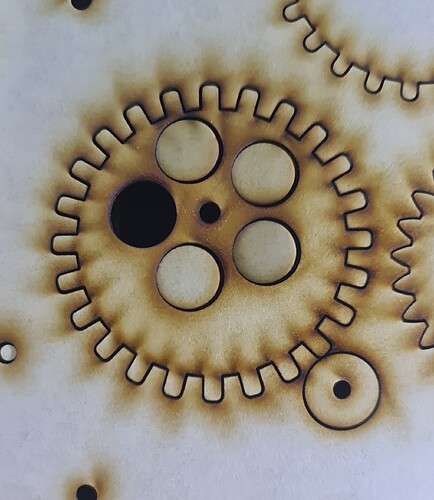

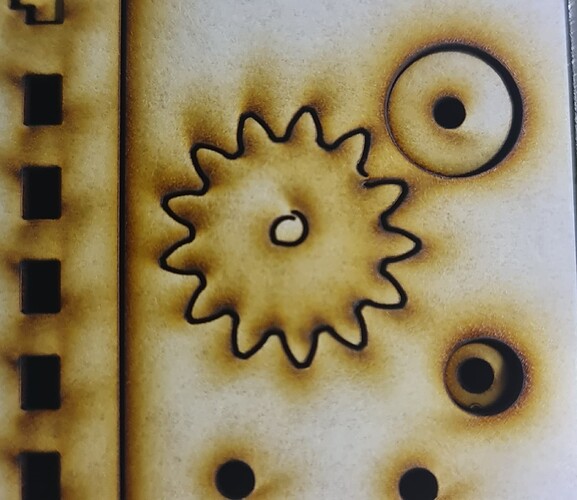

When I send the file, (a mechanical box that opens with a gear driven set up. file has 89 parts) the laser starts cutting fine then it is like the material moves and the inside and outside of parts are not aligned.

I have tried sending the file out in smaller sections, using colour mapping, I still have the same issue.

If the laser cuts the inner and outer of each part together, I don’t seem to have a problem, but it often cuts the inner part and moves off to cut somewhere else on the table and comes back later to cut the outer of the part, by than it has moved, and the inner and outer parts no longer align.

I have spoken to Prytec but they seem lost as to what the problem might be, they have said Possible causes maybe, bearing issues, belt slipping or a software fault.

I have found a lot of loose screws and a loose drive cog, I have now tightened all of these, but the issue remains.

The controller is a RDC6445G(EC)

Prytec supplied Engravelab 10 software with the laser, I have it installed on two computers, I have sent it from the two computers,

and I get the same results from both, I also installed the trial version of Lightburn and get the same result when sent from Lightburn.

Has anyone seen this issue before?