hi all…

my laser is Laser Tree LT 40W f23…motherboard MKS dlc 32 v2.1…working area frame is 600x500…2 motors on Y axis and 1 motor on Z axis.

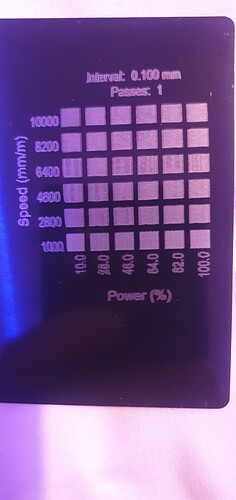

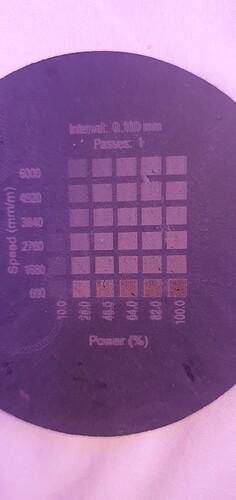

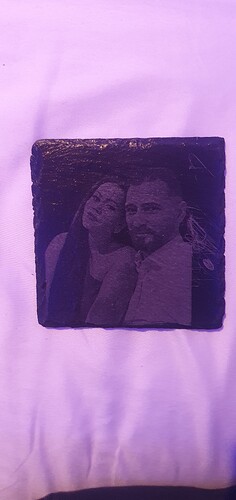

I tried to make material test and photo image on the slate coaster,and it engraved double or unclear.I tried several speeds and powers and it does the same.

Speed mm/min 2000 - 2500 - 3000 - 3500 - 4000

Power 20%

Dithering - Stucki - Atkinson

imagR - Norton black slate.

I have been trying this for 1 week. On plywood is same…on anodized aluminium same …acrylic same…of course other speed and power. I am grateful for the help

Hi Constantin,

A visual example, is always helpful.

Have you checked your X belt tension?

Definitely loose X belts.

To confirm this, try a small engrave but uncheck Bi-Directional engraving on the layer settings.

If ghosting disappears, your X belt needs tightening.

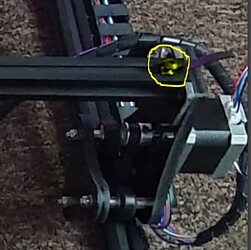

the belt is tight but i do not know how is need to tight it

Loosen this screw, stretch the belt and retighten the screw.

Also check if your laser head shakes in the support, place blocks under material to be lasered and use it a bit higher in a more stiffer position.

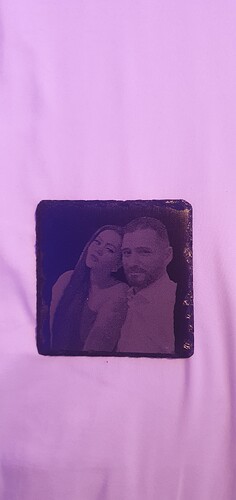

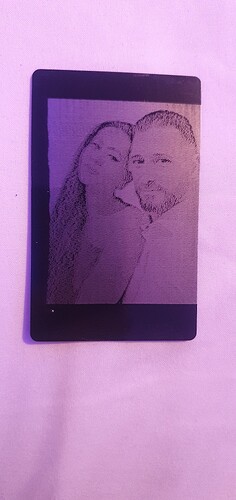

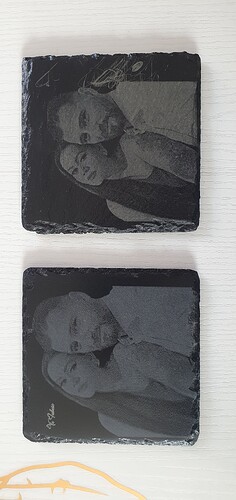

I put a 6cm object under the laser head and raised the laser head higher.

now the engraving is straight but blurry .

I am attaching pictures so you can see the difference in clarity. in both I used the same power and speed . Speed- 2700

Power- 20%

Stucki

318 DPI

the first picture was engraved 2 weeks ago

Hi Constantin

Please be super clear, even if you think you are over explaining. Quality or clarity is highly subjective. Are you happy with your new result compared to 2 weeks ago or not? If not, highlight/detail specifically to us what is bad or wrong, and what specifically you want to see different.

If you took actions, tell us what actions you took. Thank you!

I am not satisfied with either the clarity or the quality compared to the engraving from 2 weeks ago . The engraving from 2 weeks ago is on an unpolished slate coaster and what I am engraving now is on a polished slate coaster. could this be the problem?

I just noticed that the mechanical part on the Y axis has a little movement . how can i solve this.?..

Sorry…X axis

the eccentric part is adjusted to the maximum and still the wheels have a movement from the rail

Hi, I am facing some issues on my Creality Falcon 2 22W laser engraver.

Please find the link to the lightburn forum post:

Could please help me sort this out? I found another forum post where you helped somebody with a similar problem.

Also how do I know if my belts are tight enough?

Until you hear from Gil, here’s something to check out.

The Maintenance Guide from Creality that includes a video for belt tension.

Hope this helps.

![]()

@Woodcraft Problem solved, thank you so much for the article,

I did a couple of things:

-

Rechecked the belt tightness and found that when compared to the maintenance video my belts were too tight.

-

There was a bit of movement in the X axis frame, the M4 screws used to mount the X axis to Y axis are countersink type and over time the hole on the metallic frame has probably got slightly enlarged and it was not holding it firmly even though the screw was fully tight. After replacing it with a Pan Head type screw there was no more play.

-

After all this, the cutout reading stabilised at (-0.25mm). I then used Kerf Offset option in layer cut setting to adjust rather than calibrate axis.

I have tried different cutouts dimensions ranging from 20 mm to 190 mm and the results are accurate and consistent

Thank you ![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.