The exhaust fan wires directly to the power rail on my machine. Always on when the machine is on. I however deleted that fan and went with a larger external fan.

Just so that you who read all this do not get a wrong impression, I am happy with my new machine and I have known that a little optimization work is needed. To be completely honest, buying a machine that just works - anyone can do it. But having a good time modifying and fine-tuning the machine and on top of that saving well over half the money, it’s a pleasure.

I know it’s a tinkering machine. I was well aware of it before I bought mine. I still saved over $5k and will eventually have what works best for me in the end.

You are allowed to have criticisms. Anyone can buy a ready made machine. And if you can afford it? Good for you! I’m starting my journey like you, then when I have money and a stable concept I’ll move on, or keep it as a tool to create trinkets.

I have also found out the same, this also applies to the air pump. It just forces me to do the rest of the installation a little earlier, but I want to see some smoke and fire now !!

I bought this machine because I have read many user experiences, good and bad and it is the same as I am trying to contribute, my experiences and modifications.

I found the test file and ran it, though without laser on. Still, I have found out something ! The trolley I made for the laser shakes. Once the tests are over and the machine is rolled to its final location, I will put the machine on adjustable machine shoes.

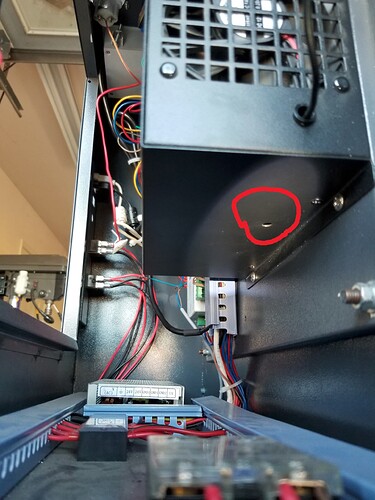

Can anyone confirm that this is the right hole for the potentiometer to adjust one’s laser power max output?

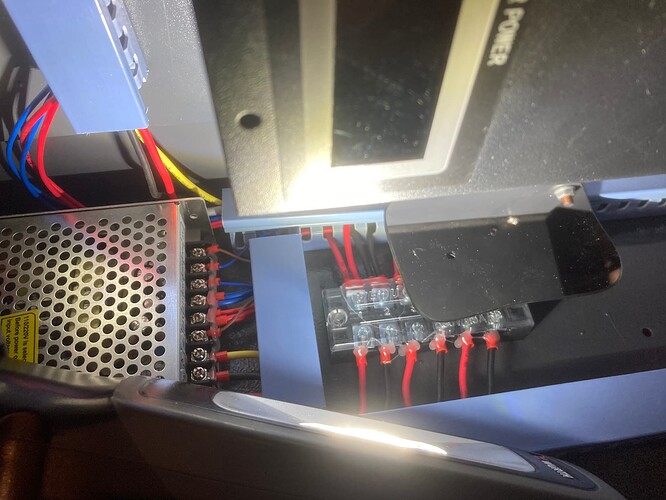

(it is a mirror on the terminal block)

I have a mirror because mine is on the right side, which is down

Taken from here

Pick up one of those sets of mirrors on a handle and you can look in there. Should see a potentiometer in there.

So, now the laser is ready for work. It took me most of the evening to align the laser beam, I could not find my special key for the small screws on the mirrors and the nozzle … Speaking of the nozzle, it was with approx. 0.8mm out of its vertical position, i.e. it pointed to the left, which could be seen very clearly by the nozzle height test.

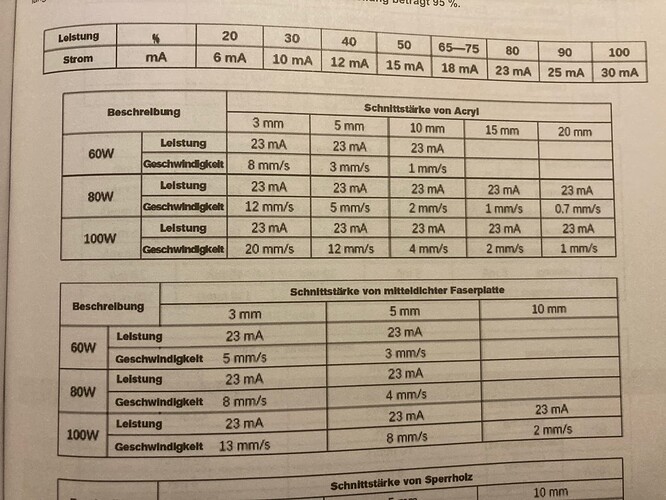

I could not do a realistic power test because I am very unsure about the max values. However, in my accompanying manual, which is intended for a machine other than mine, there is a list, with the conclusion that it is the manufacturer’s recommendation not to exceed 95% of the machine’s max power! Max power is 30 mA and 90% is 25% … see picture.

The laser tube is 1000mm long, has Ø50 and is labeled with 60 W, nothing about mA or similar. I reckon it’s probably a 50 Watt tube, but what’s your experience regarding a sensible max power setting?

It looks like mine exactly and I have used my mirror to photograph the hole

A lot of reflecting going on here!

This is from

https://thinklaser.com/news/5-glass-co2-laser-tubes-tips/

55 x 800mm = 40 watt tube

55 x 1000mm = 50 watt tube

55 x 1200mm = 60 watt tube

80 x 1200mm = 80 watt tube

80 x 1400mm = 100 watt tube

I have an 880mm 50mm diameter tube. It has a placard maximum of 21ma. I don’t run it over 18ma and generally do most of the cutting of stuff around 15ma. It measures about 44 watts with a Mahoney meter.

You have to pick a comfort zone to operate within… ![]()

Have one of these from Russ, might check it out. The doHICky comparator

![]()

… it also fits nicely with my assumption.

Russ, I’m a big fan of this kind and talented man and have, partly out of pure sypathy, seen EVERYTHING he has made. Therefore, however, it is far from certain that I have understood all of what the man has shown.

Have you turned down the max power?

By the way, how hot do stepper motors get during normal operation?

When working on mine, I’ve pressed my arm against my Y motor and was reminded how hot they were.

They draw current when they are ‘locked’, so they get pretty warm…

I forgot that they draw current to hold position and how hot they can get.

Because the timing belts are reasonably tight, to my liking, I was a little worried about my baby having fiber.

Thanks for the reply, that’s why I love the forum!

I’m a little embarrassed to have to ask, but what’s the login password for KT332N?

(I have been through the whole forum with the search function

Try this one.

RX6666

The reality is I’ve tried pretty much every known number EXCEPT this one, given to me by @micrololin

Thanks to you both

Strange that they have “hidden” this password.

The manual or the delivery note does not say anything about it either.

… the manual - mine is for another machine, that’s probably why!

OMTech definitely doesn’t know the password. I tried the three they sent then started doing randoms, you can thank @micrololin for that.