The weather is miserable, around freezing point and it is raining … ideal conditions to have a good time with your machine.

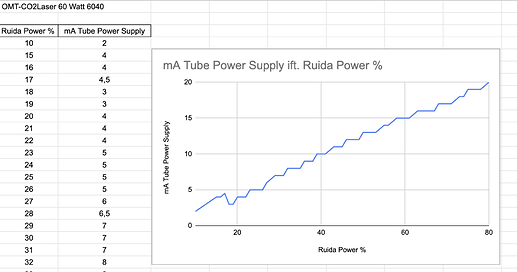

I have done a power test, all settings are made with the machine controller. Pulses of 999 ms have been used. I would like to have done the test with 3 second pulses, I think it gives a more accurate result, but I could not figure out to set times longer than 1 sec. For mA reading I used the built-in ammeter, I have not been able to drill a hole for my external ammeter, in the machine yet.

Interesting is what happens right at the beginning at approx. 17%, it actually goes down in effect. Otherwise, it’s relatively linear, I think it’s a lot different than the measurements from my K40.

I did not dare to go over the 80% / 20 mA, I am a chicken in that respect.

If there is anyone who wants the whole list of my measured values, then I would like to share it.

In the picture with the acrylic block, the values are: from 10% to 70% in 5% steps. Deepest result (at 999ms) is with 10 mA / approx. 40%.

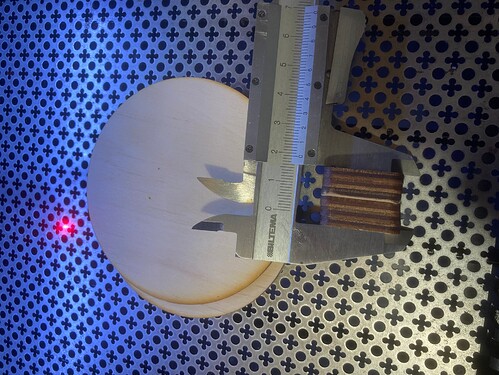

The last picture shows how deep the machine penetrates plywood with 999ms and 80% / 20mA. There is actually a small hole in the bottom round disc as well.

I am fricking jealous. My alignment was off by a hair, barely noticeable so I decided to re-align after making some wooden targets to track laser hits.

Now it’s off by a lot. ![]()

I couldn’t cut that thick of wood if it was butter and with a hot knife right now!

Also, that’s a very fancy table. Did that come with it?

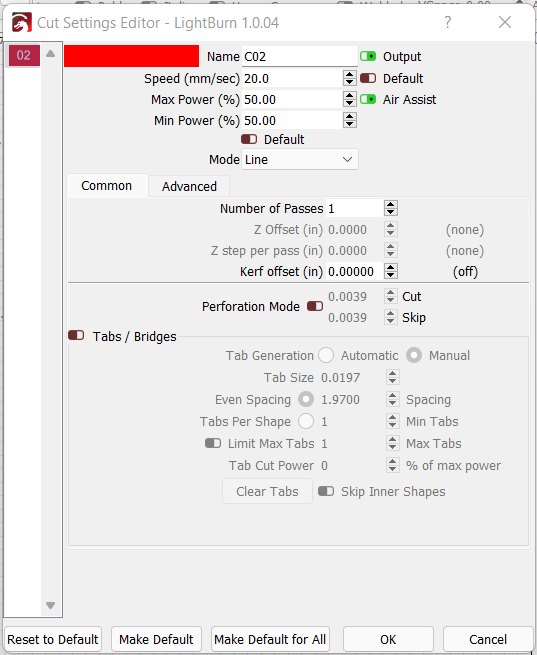

I’m actually not 100% happy with my alignment but it’s going well enough for now. But I have not cut anything because I do not want to install RDWorks and on the other hand my LightBurn activation is not working yet.

If I can cut 6mm “build” plywood which is not specifically designed for laser and is also not very expensive, then I will be happy.

The result will hopefully come soon.

On the table is a perforated plate to be used with my magnetic Punk Spikes

I have used it a lot with my K40.

Something that you’ll want to consider, and everyone who uses the stock air pump location, your machine is pumping unfiltered air through the lines and onto the lens.

It’ll be my first upgrade when I get back.

Now I have made the first realistic material tests, with the result I have hoped for. Standard plywood 5mm to 6.35mm (1/4 ") cuts this laser tube at 15-18mA and 750-650mm / min. (However the edges are not as clean as I would like them to be). Although the values are not optimized yet I am however, really happy with this result.All my “normal” 3-4mm BB plywood, MDF and HDF cut the machine significantly faster.

The ramp test I did showed that the focus height matched perfectly with what the Chinese have found. Now I make myself an angle tool again, which has the appropriate height, measured from the upper edge of the x-axis profile. I have good experience with this little handy tool from my K40.

Because I have not had it before, I think the cooling water alarm is very fine, the machine just does not start the laser if the relay is not activated.

For those who are interested in it, the material used for the laser tube foundation and the frame from the machine bed and all the doors are the same. I have measured the thickness to 1mm, if I subtract the paint we are down to 0.8mm. My old K40 has a 1.25mm wall thickness. I find this unfortunate because it detracts a bit from the overall impression and function of the otherwise quite fine machine.

What speed/power do cut 3 mm Baltic Birch ply at? Despite mine saying it’s a 60 watt, it’s the same exact tube you have. So mine’s really a 40 watt.

Oh yeah, some 60 watt I’ve got! thanks for verifying what I should be able to hit. Just a couple more hours of aligning and I should be right as rain!

Here are some gauges…

CompoundLensFocusGauge.lbrn2 (38.7 KB)

Beam Checker 2.lbrn2 (12.2 KB)

50mm-step-guage.lbrn (63.1 KB)

focus-step-gage.lbrn (61.3 KB)

My second tube for my K40 is a “real” 40 watt tube, I think and with it I cut 3mm plywood with 750mm / min x 32.5% / 8mA.

When your tube has Ø50 and is 1000mm long, it should be at least a 50 Watt laser tube. I assume mine is a real 50 Watt tube. I’m shut down for work today, it’s soon 1am. But I think I was at double the speed with my new machine regarding 3mm plywood, tomorrow I will do tests with proper documentation and keep you informed about it.

Thanks for today

Good night

Thanks for that, I know them well except Beam Checker, I have seen it at Russ but can not remember its use.

I have removed the solution mark, every time I write something LB says that there is already a solution to all my problems ![]()

Don’t let it keep you up at night.

We value your input.

![]()

I wonder if the power supply can handle an actual 60 watt tube?

My 50 watt machine from OMTech, which has a 44 watt tube (880mm) with a power supply for a 60 watt tube. It came that way.

Good morning

My power supply is also labeled with 60 Watts, just like the tube itself. It is possible that they are very close to the limit of what they can handle (PS) and therefore so often fail. With the tubes, it is almost pre-programmed that sooner or later they lose much of their effect. But if you are lucky and have a measured 50 Watt, quality tube with the equivalent PS and run moderately with it, the reserves or service life are significantly longer than a poorly fabricated 40 Watt tube, which on top of that is rated as a 50 Watt tube … The problem are without the correct gauges we do not know what we have got. On my tube it says, as I wrote before, 60 Watt and not any other technical data so I have to treat it as a 50 Watt tube.

But, friends, below the line, our “25%” problem is nothing compared to the “new 40-80 Watt” diode lasers sold today.

Generally this is a maximum current. Mine is 21ma. It doesn’t specify wattage. I guess you get what you get.

My understanding is that if you run it at max amperage it will produce, as in your case, the 60 watts.

Assuming you couldn’t find it on the internet. You could probably measure the watts out at 50% along with the ma meter and have some idea of max ma.

I have mine set so 85% is 18ma. I usually don’t exceed about 80% which is ~15ma, where I can cut about anything I’ve needed to cut.

Interesting. With the tests I did yesterday I get at 80% -20mA and at 75% -19mA and at 73% -18mA,

so I would think that about 73% will be my self-determined max power.

The manual says: recommended max power 95%, it seems incomprehensible to me.

Should not your scale be below mine when you have a 60Watt PS and a 50Watt tube? - I do not understand the logic of it.

Here is the first material test. For reference, there is a sample from my K40. It corresponds to 12.5 mm / s. (I am about to switch to mm / sec)

The test itself I did a little too conservative, with 60 and even 70 mm / s it is probably also possible to perform a clean cut with 65% and 73% at 40mm / s or faster. The label at the top unfortunately does not quite fit the reality, 75% corresponds with my tube to 19 mA, which I probably will not use, max 18 mA will be safer, I think.

The row with 10 mm / s is quite dark in cutting, however, without it spreading. The cuts are really nice from 30mm / s and up. 45% at 40mm / s could be my favorite. (45% corresponds to approx. 11.5 mA) The new laser machine is over 3 times faster for the same task than my K40, it is a bit impressive for me.

Here’s what I achieved beyond my “normal” work today. The 1/4 "plywood is a construction site material and the result is not beautiful either, but still cut in one go. For the other materials, the trend from the first 3mm plywood test can also be seen here, everything happens a little softer and somewhat faster, it is nice.

I am missing the ordered punk spikes, it is quite clear to see that the items are much dirtier than “normal” when I cut at a distance to the bed.

Tomorrow I will in my free time explore a bit how max / min power works, right now I have set both values to the same, but I have no idea if it is okay. With Gerbil there has not been this feature for my other 2 lasers. If there are any wise ideas regarding this subject, I am very responsive.