I have the xTool S1 and I can’t get it to move with the move arrows even with the lid shut. Will lightburn be able to make the software more compatible with the S1? And is there a way of enabling the move buttons?

Steve,

Did you install the configure file from Xtool?

Yes i have used the file from xTool, i have since found out that i need to leave the enable jogging tab disabled. So it works somewhat bit im hoping lightburn will publish a better version.

Oh ok great. I haven’t been able to get my S1 to work properly with LB. I’ve given up and just use Xtool Creative Space unfortunately. The machine works great XCS just doesn’t compare to LB though.

Same here. The config file from xTool is woefully lacking. I’m sure hoping that LightBurn gets “real” support for the S1 soon. At the moment I’ve just given up and use XCS, but that means that I don’t have project portability between my lasers. I was really hoping to use the S1 for prototyping, but that doesn’t work if I can’t reliably use LightBurn to run it.

The Clack Shack YouTube channel has a much improved settings file for the S1. He also has some good tips on the S1.

Maybe real question is when will xTool start supporting Lightburn.

Actually, I think it’s the other way around. When will Lightburn start natively supporting the xTool S1.

Lightburn already supports most of the xTool lasers. The S1 is pretty new and adds some new functionality and features that aren’t available on other lasers. These features need to be integrated into Lightburn. They have stated that they are working on it, but we are still awaiting the release that includes that support.

xTool has released a device profile for lightburn for the S1 that provide basic support. But to incorporate some of the feature supported by XCS requires pretty extensive update to Lightburn, adn that’s on them to implement.

I now use both Lightburn and XCS on my S1. While I prefer Lightburn in most cases, there are some project that are just faster and easier under XCS at this point. And there are some things such a irregular surface engraving that simply can’t yet be done with Lightburn.

I find XCS a very good tool, and defintiely a lot easier for beginners and hobbients. But Lightburn has much better functionality for more advanced users and production operators.

I’m hoping support for these advance features in Lightburn is coming soon. I’d rather use Lightburn for everything, if for no other reason compatibility with my other lasers.

This depends on both companies having a cooperation, and from what i seen Xtool is not very open to do this. Lightburn can only support what in the realms of GRBL.

Anything outside that and proprietary needs to be a 2 way street kind of thing

From my understanding, xTool has a proprietary business model, rather than an open approach. I don’t think Lightburn crew just said we aren’t going to bother supporting xTool for no reason.

XCS is closed, locked, proprietary and xTool controls the content/art created there.

You may find Paragraph 2 Section 10 quite interesting. I did.

https://www.xtool.com/en-au/policies/terms-of-service

The specifications for LightBurn are Documented and GCode is a published standard. Our team is also adding new equipment as quickly as we can. xTool definitely claims to offer ‘LightBurn Compatible’ hardware.

I’ve seen xTool make at least two (possibly three) unannounced changes to their firmware on the xTool D1 / D1 Pro to put speed limits on the GRBL rotary control. Currently, I know of at least two users who are struggling with Rotary devices on their xTool D1 engravers. I can’t tell if the latest xTool Firmware allows GCode control of the rotary device.

When they made changes, or design decisions, historically they haven’t shared this information with us. They’ve got a lot of different machines out there and they seem to be a moving target and securing their IP.

Some new features are scheduled for LightBurn 1.5.xx that should help address some of the firmware customizations. This will allow several users to more readily adopt odd, non-standard hardware, and even custom projects like Drag point engravers, Plasma Cutters, Quilting machines and other wonderful things.

If a Manufacturer of Laser Engravers wants to be less ‘LightBurn Compatible’ than a revitalized drag-point engraver or a quilting machine, that’s their prerogative.

We are constantly moving to support more hardware all the time. We may not immediately support each and every “weird-duck” machine with 1% of the market, but nerds love weird machines so we’ll get a lot of them. The further a design is from the current knowledge base and current standards, the longer it will take. Ruida was a “weird-duck” when LightBurn began to reverse engineer the controller. Ruida had a huge market share and their software was notably… er… uhm… “Inspiring”… ![]() When a Reverse Engineering cycle is required, it can take a while and it can be expensive. It might take us a while but I’m confident that we’ll get there.

When a Reverse Engineering cycle is required, it can take a while and it can be expensive. It might take us a while but I’m confident that we’ll get there.

It is possible to have Lightburn drive an S1 via WiFi? I know it works as I did it with XCS, but setting it up in Lightburn is not obvious.

I don’t believe this is known yet. We can communicate with several controllers over wifi, but xTool tends to do their own thing. If xTool selected standard GCode for their controller and a standard TCP connection to communicate with it, I could say yes and walk you through the connection procedure.

I have an active MKS-DLC32 on my desk communicating with LightBurn over WiFi. MKS controllers are made by MakeBlock, xTool’s parent company. It works as expected… ( Well… the screen didn’t work ‘out of the box’ and I had to flash it with their new firmware - but it’s fine now.) I ran it for a couple of days - it’s nice and stable.

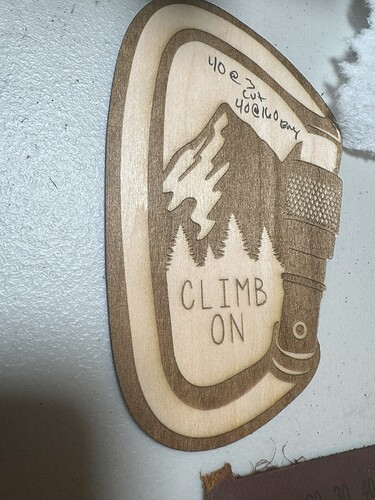

Well ive been playing around with the lightburn settings for my xtool s1 40w, and these are some of my findings, enabling fast whitespace scan makes the laser speed run erratically when engraving, so thats turned off. Enabling the jog button in settings means the jog control button under the move tab won’t jog, so thats turned off and continuous jog doesn’t work either way. So come on lightburn your software is still better than xcs in my opinion but it still needs work to be even better with the xtool s1 40w .

Have you also hit xtool up and ask why they claim they are Lightburn compatible when they aren’t?

Perhaps it would be better for LightBurn to concentrate on the machines / controllers from the manufacturers who offer their cooperation and the necessary data to be able to integrate these machines into LightBurn. It will save a lot of frustration and free up resources for existing partners and customers.

I’m sure in the future it will say they are “verified” for LightBurn on laser machines, or customers will find other brands.

I was using Lightburn for about 1.5 months until I just got an XTool S1 20W. I really like the Wifi connection so just used XCS but really struggling with the output quality of the S1 not being anywhere near my Creality Falcon 2 22W.

I’m trying Lightburn now with the S1 and it works ok. I’m wondering if people noticed changes in quality between platforms or strictly just different features?

While the S1 has a number of issues by all accounts it seems to be mechanically sound. What specific quality issues are you seeing? Showing some comparative photos of the output between the machines may allow others to comment on what might be going on.

Every laser will have its own characteristic properties but I wouldn’t expect drastically worse output quality from the S1 vs other flagship models.

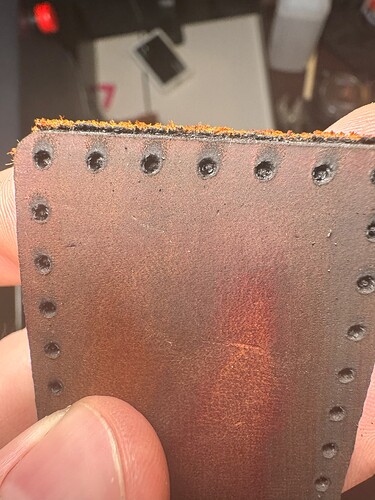

I am seeing lots of issues with scorching and smoke staining. My biggest issue right now I am working with their support on is this leather that wont get a clean cut like my Creality. We tried everything so far, speed and power tests of course, adjusting focus, multiple passes, etc. I got near perfect results at 85 @ 4 mm/s on the cCreality and can’t even get close to that on the S1. For wood, it always seems like the smoke stream goes towards the vent which makes sense but causes smoke stain on wood for most settings. I have air assist and tried auto and manual on all settings…

Interesting. Following closely as the S1/F1 combo is on my short list of likely replacements for my dead CO2.

I know it is not 100% with LB but it will either get better or I’ll have to work hybrid for the odd times where I want to do uneven surfaces or any of the other fancy things that they claim can only be done through XCS