Hi.

You’re welcome.

While LB forum engine is one of the best (of the few  ) that I’ve came across, it still has its peculiarities.

) that I’ve came across, it still has its peculiarities.

But I feel that us xTool owners are in the same proverbial leaking boat, so I’m confident that when problems arise, there’s always someone who can point us in the right direction to patch at least some of the holes.

So the folks at Makeblock must’ve done something to rectify the issue  .

.

Or the focus varies a lot between the units  .

.

In any case, on Yours it’s better, but obviously not perfect.

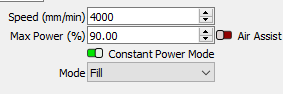

While the IR head (or any laser for that matter) will work to a degree when out of focus -either intentionally or unintentionally- power has to be increased and/or speed reduced, sometimes rather dramatically.

And as I said earlier, contrast always suffers.

That’s worse, but if the rise is linear, all You have to do is to shim the legs or to fabricate adjustable feet.

If the rise is not linear or if a straight edge test reveals that the gantry is bowed, a warranty claim might be the best solution.

While the xTool frame does look very pretty and well thought of, there’s always room for improvement and fine tuning with anything budget oriented.

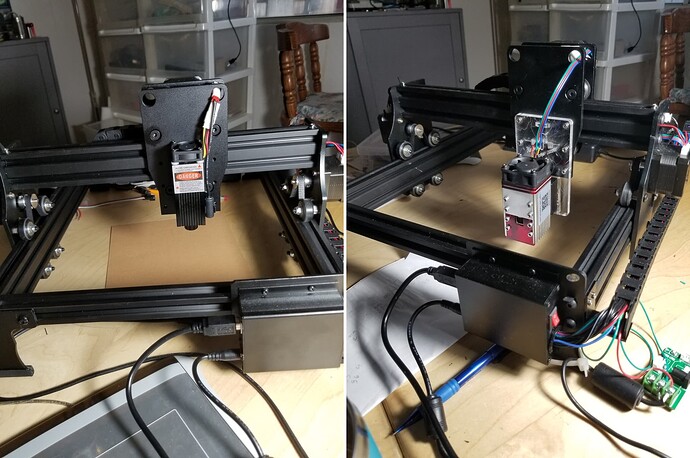

My only experience is with xTool frame, but it did require some squaring up in assembly stage.

Very little, but still.

From what I’ve read over the 'net, most of the budget machines/frames need much more tinkering to get everything absolutely right.

Because of the way I wanted to fabricate the enclosure for mine (ATA style), I did turn adjustable hard plastic feet on a lathe for mine to fix the machine rigidly onto the bed for transportation.

All the initial testing was done with the 20W “Blue” head, so I didn’t find any problems with the feet lengths measured and equalized only with a vernier caliper.

I assumed that I have to revisit them anyway when I start to use the whole bed with the IR head.

And again when I eventually make the bigger ATA style enclosure to be used with the extensions.

I somewhat regret choosing Makeblock as well, but for different reasons  .

.

I was a bit blinded by the pretty and well thought of looks and features, and the praising (paid?) reviews.

But, for the more budget oriented hobbyist like me, I feel that D1 Pro still offers a good -perhaps better than the competition- platform for improvements.

If I’d bought the machine solely for making profit, I would have looked for industrial machines with 10 times the budget.

Could the marketing be more truthful: Yes.

Could the price be lower: Always.

Could the work area be larger: Definitely.

Could the XCS work with older less powerful laptops: Heck Yeah.

Etc.

But…

Given the fact that both the 5W+ and especially IR diode lasers are very much in their infancy, I for one gladly take what is offered, for a price I can afford.

I would really much like that there wasn’t any tinkering required and I could just design and cut/engrave/mark since for me the laser is just a tool, but at this price point it won’t happen.

A degree of realism is always needed when diving into something brand new, no matter the claims the marketing departments or paid reviewers make.

OTOH, It’s been a quarter of a century since I studied industrial scale lasers more throughly while at Poly, and those beasts did require a lot more work to optimize the productivity.

And both the cost of the system and the running costs were astronomical.

And any downtime for whatever reason did cost the company dearly.

Also, no-one in their right mind would’ve assumed that in a few decades first the CO2:s and then other lasers capable of precisely cutting anything tougher than a sheet of paper would for a reasonable price be available to the general public either.

So, even if it doesn’t always feel that way, I for one think we do have everything very well indeed  .

.

Regards,

Sam