No official response yet - would appreciate some feedback from the dev’s.

Thanks

No official response yet - would appreciate some feedback from the dev’s.

Thanks

I’m active mostly on the snapmaker forum, but I figured I’d create an account here and help those I can over here. ![]() I’ve written a couple guides on using the rotary with lightburn and have had a lot of good results. The two guides are as follows:

I’ve written a couple guides on using the rotary with lightburn and have had a lot of good results. The two guides are as follows:

Standard guide to generate proper gcode and use the USB drive and setup on the machine itself:

Absolute full control guide, not really recommended to start out with and is sorta complex, but great for repeating projects.

Welcome and thank you! ![]()

Thanks for the welcome. ![]()

EDIT: Awe I got marked as spam for linking to my guides and hidden. ![]()

Fixed. ![]() Should be good now.

Should be good now.

Welcome! Happy to have more Snapmaker folks around. We have some incoming as Support machines. The Artisan, in particular. About to order it, anyway.

Thanks, it’s hard being a new user with guides explicitely on another site. ![]()

Thanks! I’d absolutely love to tinker and write guides for the Artisan, but it’s just… waaay over my current price range, had to settle for an XTool D1 Pro 10W for now (mainly because sale + coupon). Maybe my current 2.0 series guides can work with the Artisan?

I’ve passed along a link to the Support team member getting the Artisan for review ![]()

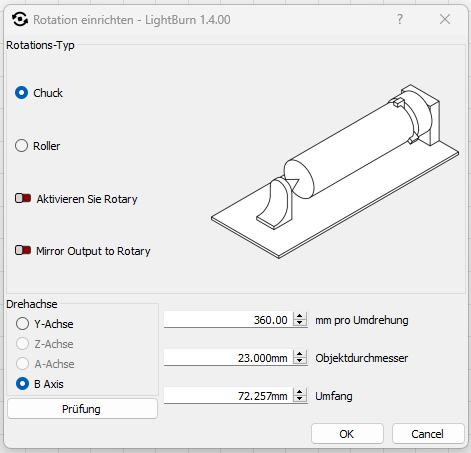

Any news here @Colin ? I am also a snapmaker Artisan user and bought a Lightburn license to work with it. To normal mode is working more or less fine, after some configuration but still problems with the rotary module of the Artisan. The “Test” sequenz spins the rotary (in the settings I can only choose Y-Axis or B-Axis. I chossed the B-Axis but problem is, I can’t use 360°. It shows 360mm/U) If I try to laser something, it moves the x-axis what should never happen. X-axis must be in the middle position all time long (and only rotary should spin). Any idea what the reason could be?

We still don’t have a device on hand, they expect to ship in June

Any advice to my problem? Why I can’t choose the A-Axis? @Colin

I suspect a change needs to be made on our end, which we can do once we have a device on hand for sure. I’ll pass this through our Developers and see if we can fix it before then.

Any Update about Artisan?

It just arrived to one of LightBurn’s support agents, and has yet to be built.

Machine has been set up, and the Rotary module arrives on the 25th

@Colin looking forwaard to Snapmaker Rotary support. If this would work that would be really great. The Snapmaker hardware is perfect but Luban software is horror. If Lightburn would fully support Snapmaker and Rotary module (maybe also camera) would be a big step in the right direction. Thank you for your update.

Hi there, jsut registered as I wanted to try Lightburn for our Company and encountered the same problem.

By setting the console to show everything, I found out that LB sends this command for rotation:

G1 A-10F6000 S0

As in a image shown above, LB only gives us the option to use either the Y or B axis, so why it tries to move the A-Axis?

Running the G-Code with the correct Axis manually results in having the rotary act as required.

G1 B-10F6000 S0

So, it seems to me, that someone messed somthing up in the configuration tool ![]()

Still waiting for a fix. Luban is so buggy … but currently no alternative with the rotary module. Please Lighburn Support let it happen ASAP … Thanks in advance.

You can have them try my guide. I know they “sort of” implemented inline controls on the 2.0, I’ll assume the base code would be the same for the Artisan. The main issue with how they implemented it (and why my guide has custom firmware) is one of the merges has a safety flaw and does not turn the laser off when S0 is called, instead it stays at the last power used. If you replace S0 with S1 it reacts properly and the laser is too weak to burn anything and acts like ‘off’. It also uses a 1mm retap on the homing switches with rapid movements causing it to never be the same (sometimes it hits hard enough the 1mm retap isn’t far enough to disengage the limit switch), I changed this back to 3mm.

As such, maybe try my guide without flashing the custom firmware (it’s made for the 2.0), since it can be assumed inline should be in the codebase, just be aware of that safety problem.