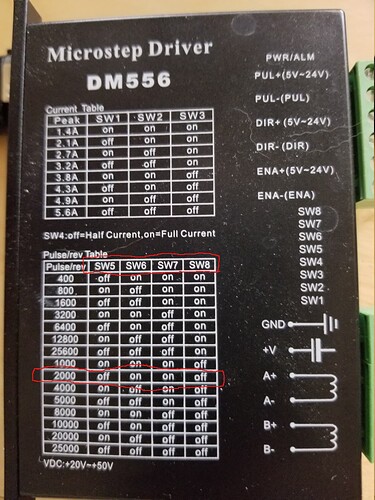

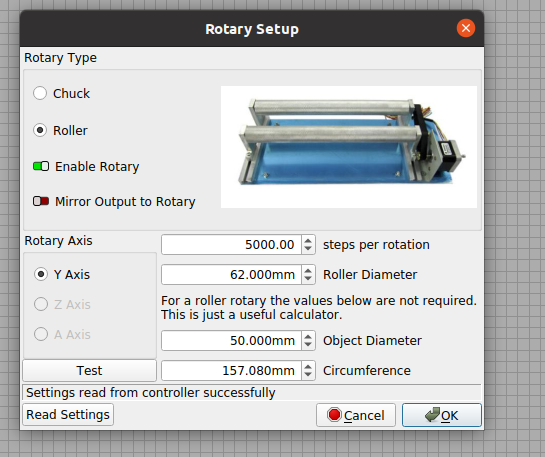

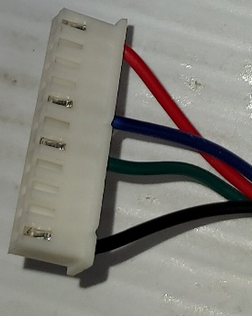

I have a Monport 55w Co2 laser. Just bought a 4 wheel rotary attachment for tumblers. I’ve gone into light burn and plugged in the wheel diameters and the diameter of a test piece “tumbler”. What I’m not sure about yet is the steps per rotation number to plug in. I’m trying to get that from China. Their US support tech doesn’t support accessories, just the laser.

I created a letter H with a fill setting. All I get is a small line being burned into my wooden test tumbler. The laser makes around 6 passes back and forth.

I’ve included a link to the image.

Do I have to “write” the configuration in light burn into the Ruida Controller for this to work? One of my steps per the US tech support tells me that when I’m done with any rotary job, I should disconnect the Y-Axis cable from the rotary, plug in the regular Y-axis cable, and press the reset button on the controller window on the laser.

What am I missing short of the steps per rotation?

https://drive.google.com/file/d/1jX2vzAwxpiKJIYdkIoGhFqLRejkQhX4d/view?usp=sharing